A small drying box

A drying oven, small technology, applied in dryer combination, drying solid materials, drying and other directions, can solve the problems of single material placement, uneven drying, low quality, etc., to achieve good material quality, convenient material drying, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

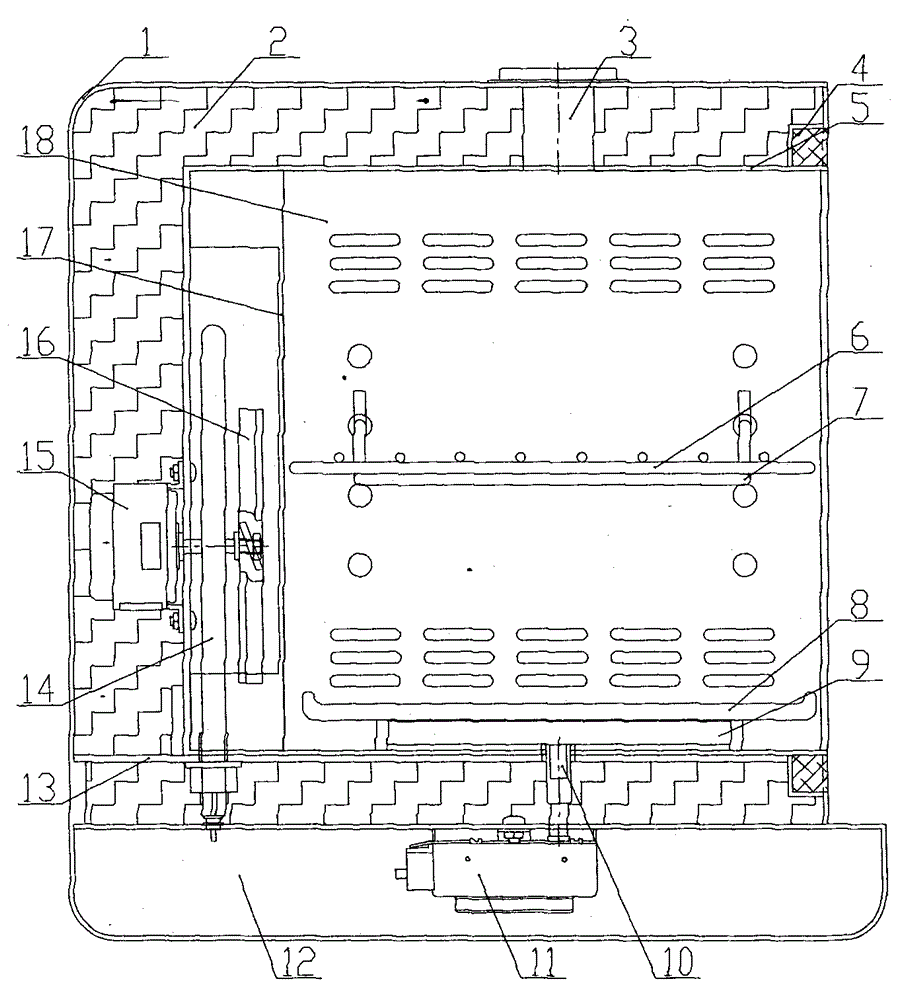

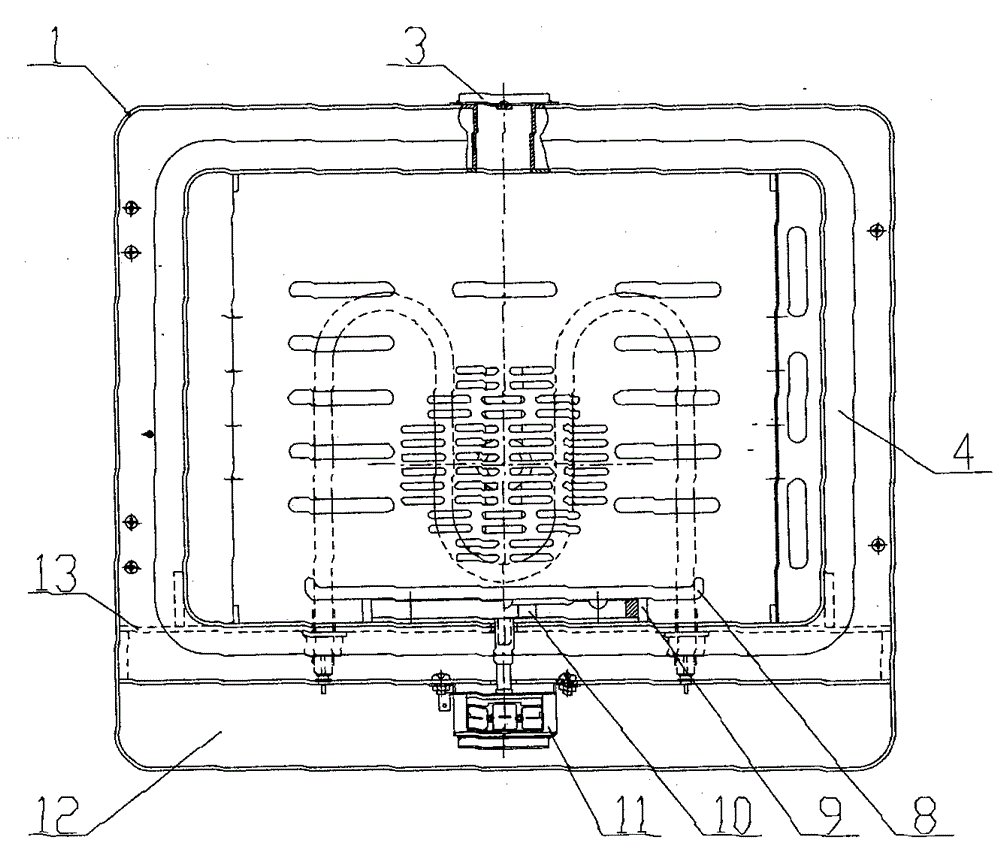

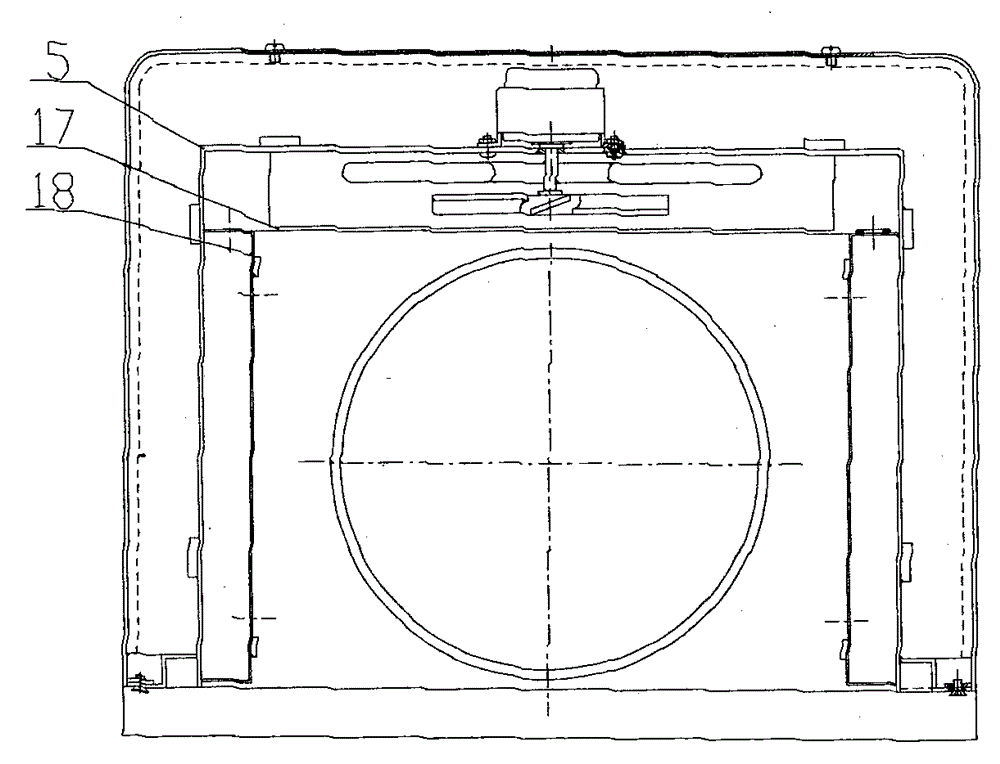

[0022] combine figure 1 , figure 2 , image 3 and Figure 4 , The small drying box of the present invention includes a drying box body 1 and a drying chamber 5 for drying materials. The heat insulating material 2 is filled between the drying box body 1 and the drying cavity 5 .

[0023] The drying box 1 includes a drying chamber 5 , a carrying plate 13 , a driving motor 11 , and an electric control box 12 . The upper side of the drying box 1 is provided with an exhaust hole 3 through which the humid air is discharged. The drying chamber 5 is installed above the carrier plate 13 and fixed by positioning pins on the carrier plate 13; the driving motor 11 and the electric control Casing 12 is installed on the bottom of drying box body 1, and drive motor 11 is fixed on the drying box body 1 by bolt, and the vertical rotating shaft of drive motor 11 enters in the drying cavity 5 through the inner plate of drying box body 1 and carrying plate 13.

[0024] The drying chamber 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com