MEMS microstructure plane displacement measuring method

A technology of displacement measurement and microstructure, which is applied in the direction of measuring devices, special data processing applications, instruments, etc., can solve the problems that the measurement resolution cannot meet the requirements of MEMS microstructure planar motion measurement, and the calculation amount is large, so as to improve the accuracy and high The effect of precision measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

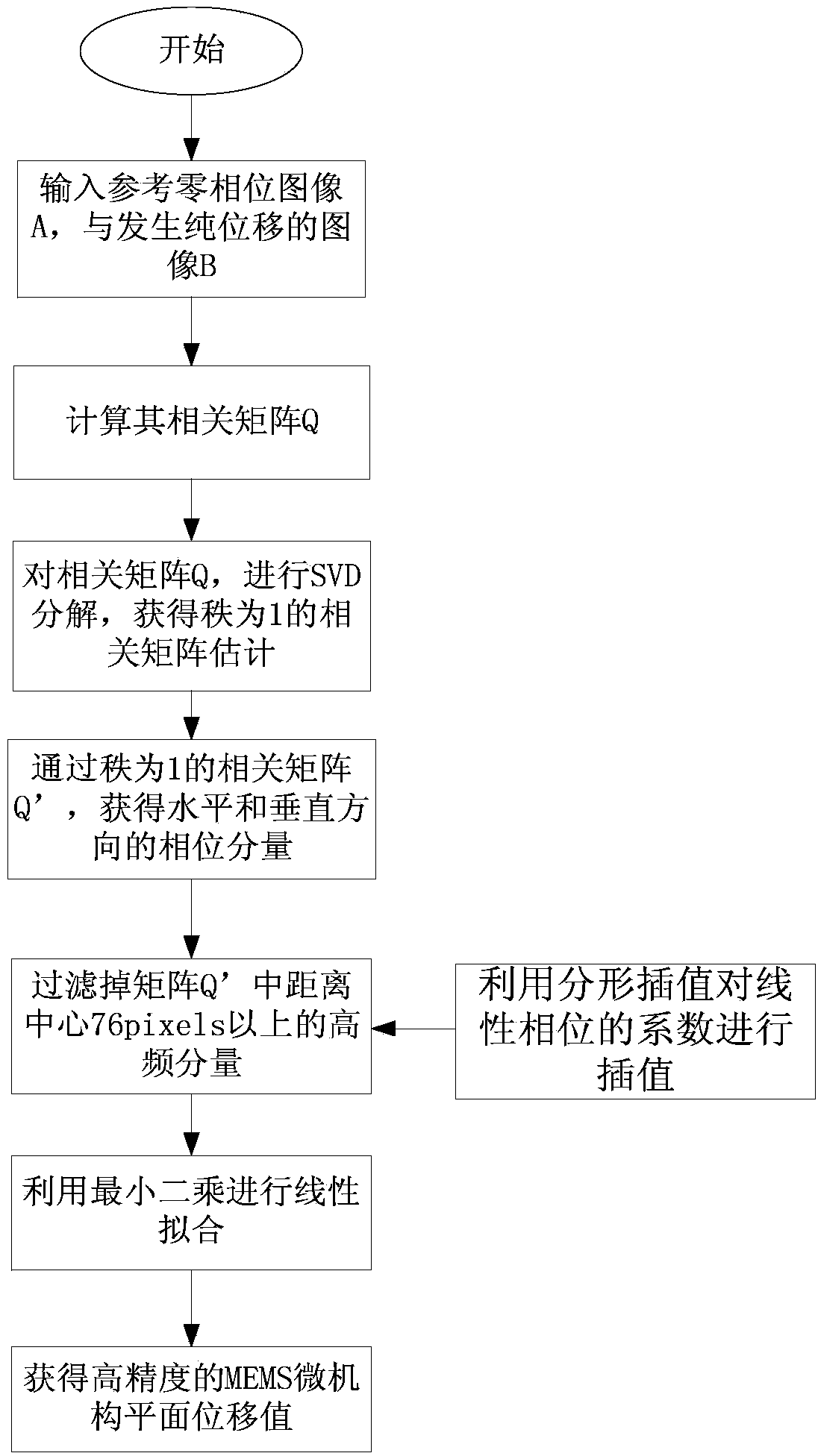

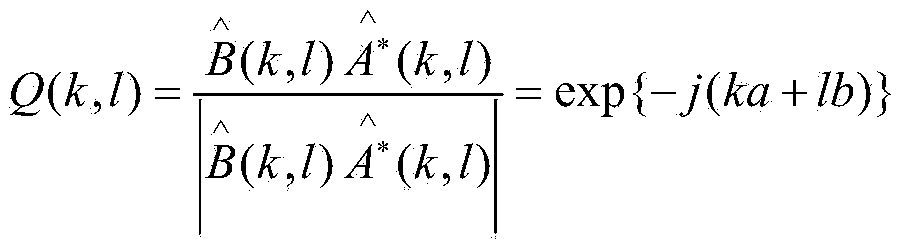

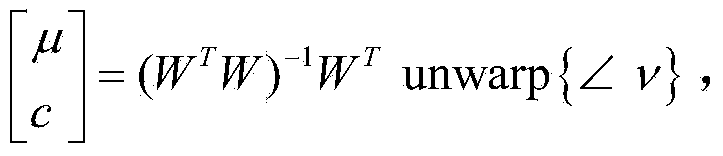

[0013] By adopting the method of the present invention, the influence of different lighting on the collected images is avoided; since the rank of the phase correlation matrix of the image is one without noise interference, the singular value decomposition technology is introduced to reduce the amount of calculation in the phase correlation measurement method, and the linearity obtained The phase coefficient uses fractal interpolation to reduce noise and improve the measurement accuracy. The least square method is used to fit the linear phase coefficient of the singular vector to obtain the slope of the fitted line to achieve high-precision MEMS microstructure plane displacement measurement.

[0014] Below in conjunction with accompanying drawing and specific examples the implementation of the present invention will be described as necessary, as figure 1 It is a flow chart of MEMS in-plane displacement measurement in the present invention. Including the following steps:

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com