Emulsion matrix stability detection device

A technology for emulsification of matrix and detection device, which is applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of destroying the emulsion to be tested, long measurement time, insufficient measurement accuracy, etc., and achieves a simple device structure. , The effect of high measurement accuracy and convenient maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

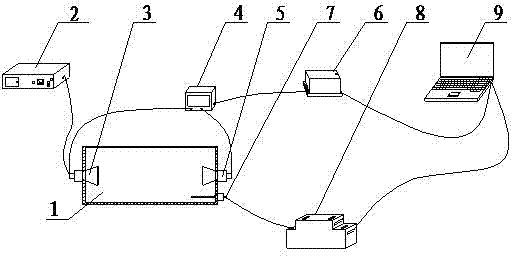

Method used

Image

Examples

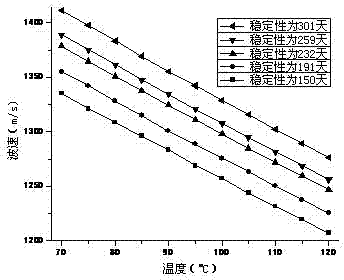

Embodiment 1

[0044] Prepare emulsification bases with the same formulation and different stability as the tested emulsification base 1, and use ultrasonic waves with a frequency of 40 kHz to measure the ultrasonic time of emulsification bases with various stability at different temperatures and with a sound path of 50 mm. The experimental results are shown in Table 1; The ultrasonic wave velocity converted from the above formula is shown in Table 2; the ultrasonic wave velocity standard curve of each stable emulsified matrix at different temperatures is shown in Table 2. figure 2 . The measured emulsification matrix 1 uses ultrasonic detection with a frequency of 40kHz. The temperature sensor measures the temperature of the emulsification matrix 1 to be measured at 105°C. The ultrasonic wave is measured by the ultrasonic transmitting transducer, ultrasonic receiving transducer and timer at a sound path of 60mm. The propagation time in emulsification matrix 1 was measured to be 46.7 μs, an...

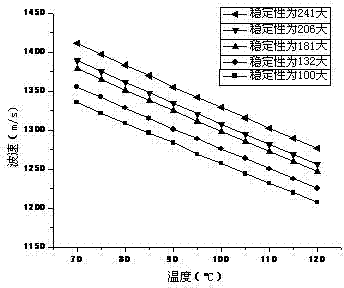

Embodiment 2

[0056] Prepare emulsification bases with the same formulation and different stability as the tested emulsification base 2, and use ultrasonic waves with a frequency of 28 kHz to measure the ultrasonic time of emulsification bases with various stability at different temperatures and with a sound path of 90 mm. The experimental results are shown in Table 3; The ultrasonic wave velocity converted by the above formula is shown in Table 4; the ultrasonic wave velocity standard curve of each stable emulsified matrix at different temperatures is shown in Table 4. image 3 . The measured emulsification matrix 2 is detected by ultrasonic waves with a frequency of 28kHz. The temperature sensor measures the temperature of the emulsification matrix 2 to be measured at 90°C. The ultrasonic wave is measured at a sound path of 80mm by the ultrasonic transmitting transducer, ultrasonic receiving transducer and timer. The measured propagation time in the emulsified matrix 1 is 57.3 μs, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com