Arrayed micro gas chromatographic column chip with super-large contact area

A micro-gas chromatography and chip technology, applied in the field of chromatographic analysis, can solve problems such as difficult separation, small attachment surface area, and limited ability of chromatographic columns to separate components, and achieve the effect of improving the ability and increasing the attachment area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

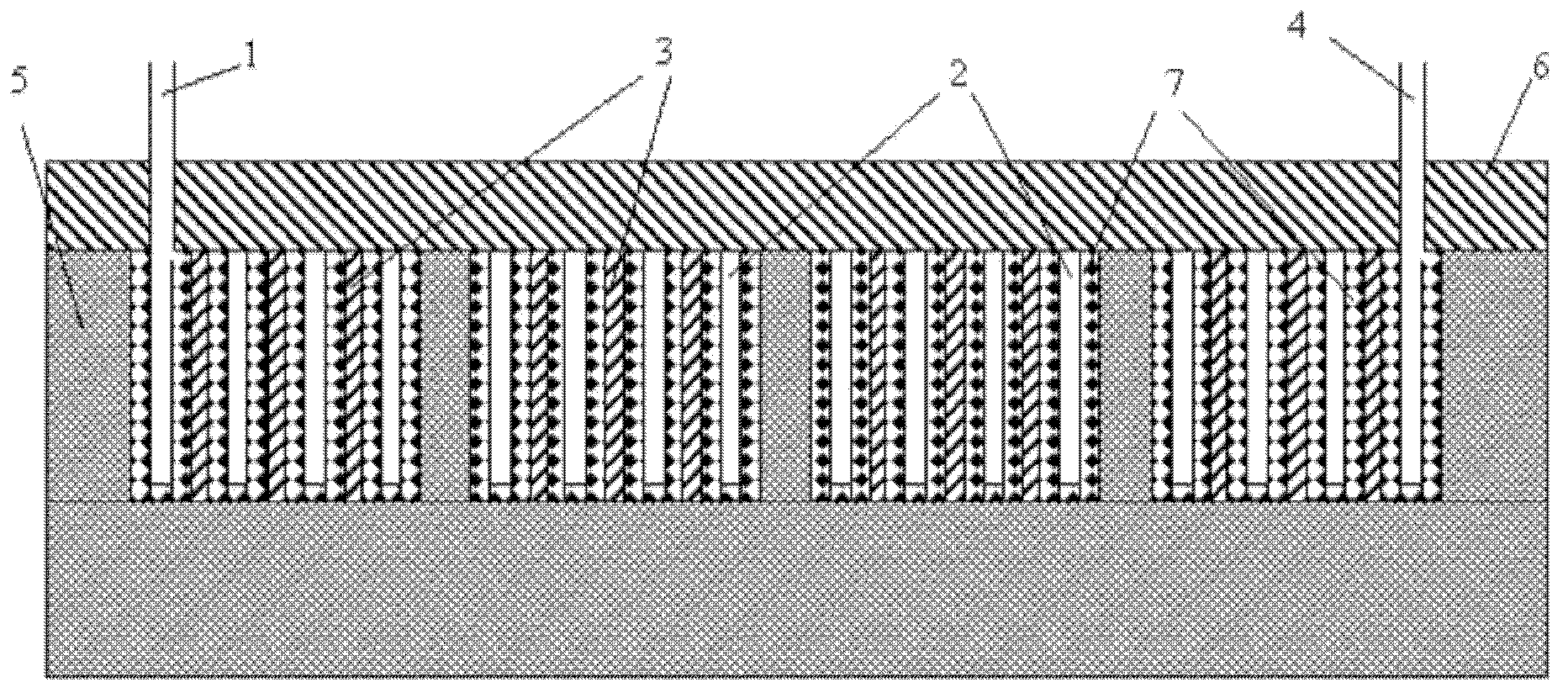

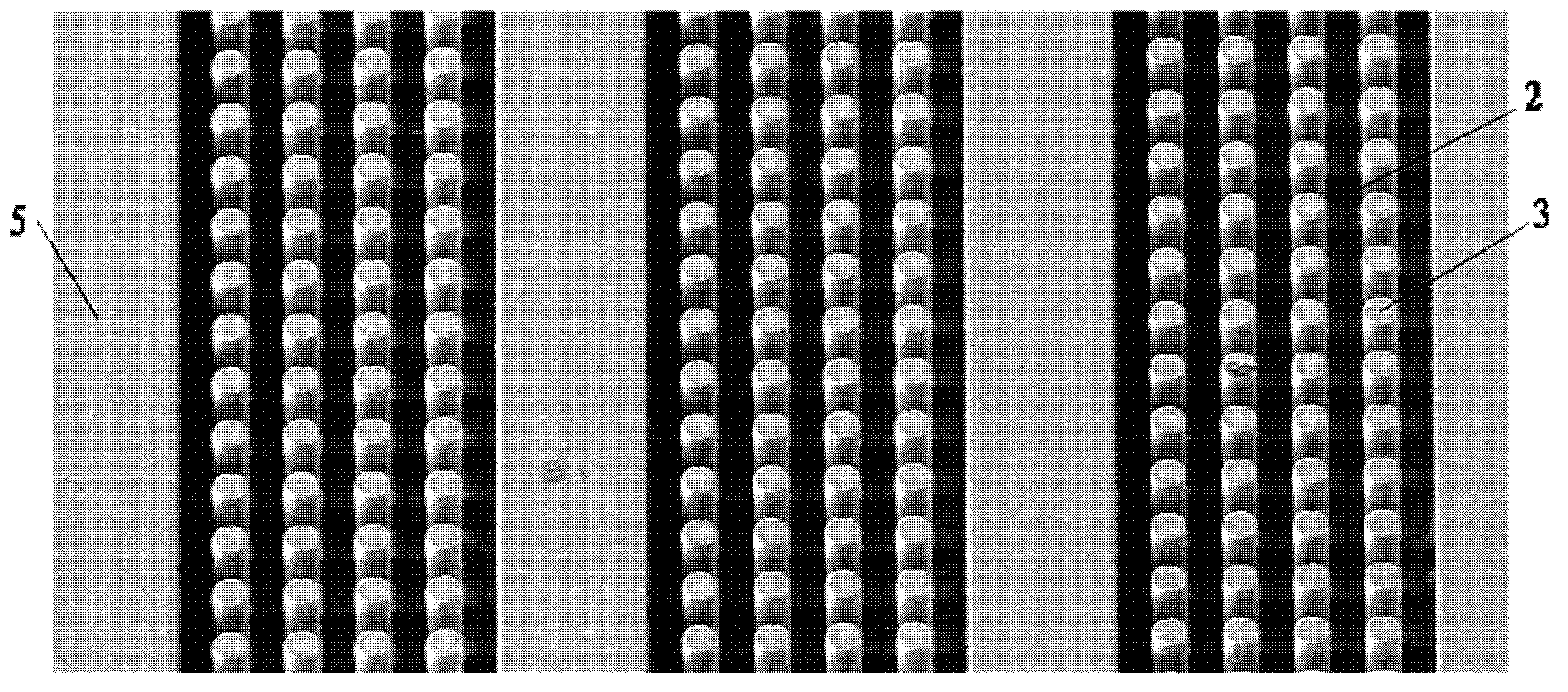

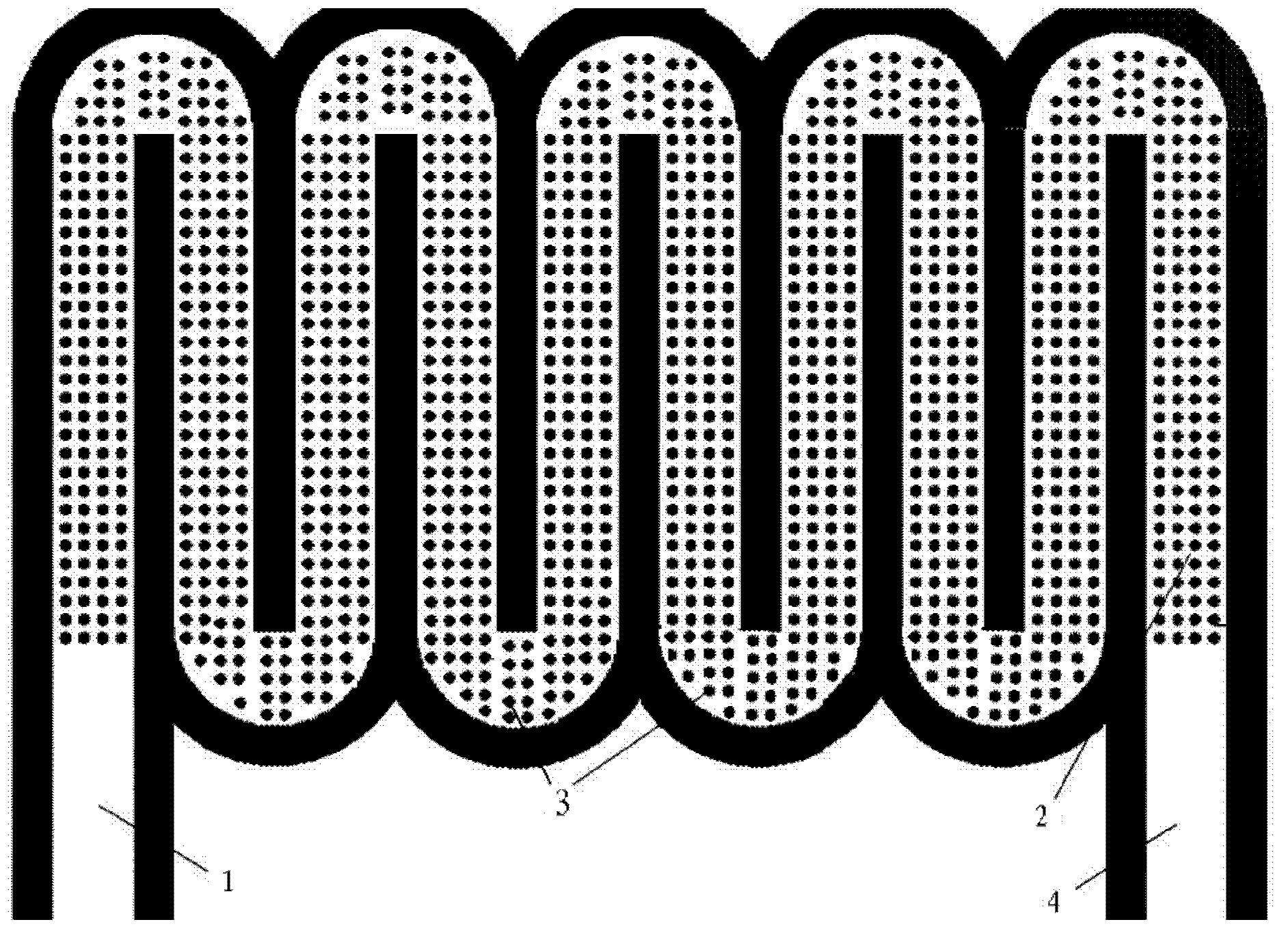

[0029] The present invention proposes an arrayed micro-gas chromatographic column chip with an ultra-large contact area. By setting arrayed columns in the channel of the micro-gas chromatographic column, and through electrochemical corrosion, the surface of the micro-gas chromatographic column channel and the array A layer of porous silicon is grown on the surface of the chemical column. Because the structure of porous silicon is loose and porous, its surface area increases by tens of thousands of times. Therefore, fixing the stationary phase on the surface of porous silicon can greatly increase the attachment of the stationary phase in the chromatographic column. area.

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the arrayed micro gas chromatography column chip with super large contact area and its preparation method of the present invention will be described in detail below in conjunction with specific examples and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com