Toner, development agent, toner container, and image forming apparatus

A toner and colorant technology, which is applied in the field of image forming devices, can solve the problems of image quality deterioration, heat-resistant storage or fixability reduction, base soiled images, etc., and achieve good heat-resistant storage and fixability, The effect of suppressing the deterioration of image quality and maintaining the coating effect for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0260] [Developer X1]

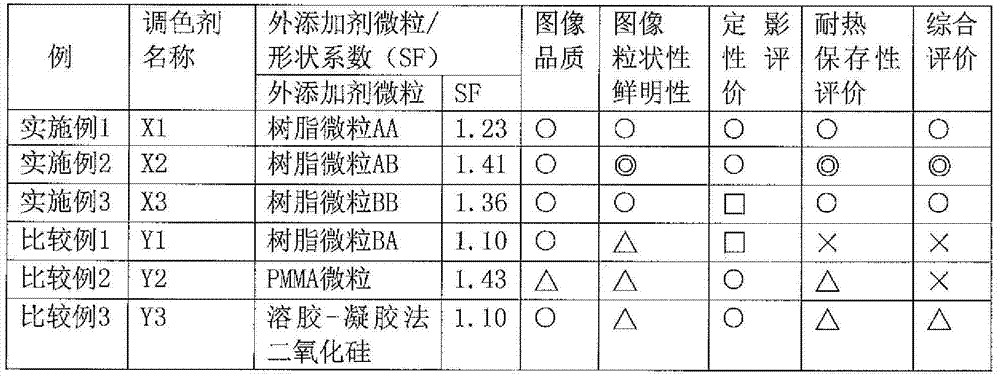

[0261] (Toner master particle A) 100 parts, and 0.75 parts of rutile-type titanium oxide treated with isobutyl with an average particle diameter of 15 nm. In the Henschel mixer, the peripheral speed of the stirring blade is 35 m / s mixed under conditions. Thereafter, 3 parts of resin fine particles AA having a silica layer formed on the surface were mixed in a Henschel mixer at a peripheral speed of a stirring blade of 35 m / sec to prepare [Toner X1]. [Toner X1] The shape factor (SF) of the resin fine particle AA when attached to the surface of the toner mother particle fine particle A was 1.23. It is reported together with the value of SF in Table 1 described below.

[0262] 7 parts of [Toner X1] thus obtained and 93 parts of [Carrier] were mixed and stirred to prepare [Developer X1] having a toner concentration of 7% by weight.

Embodiment 2

[0264]In Example 1, the peripheral speed of the stirring blade of the Henschel mixer was changed from 35 m / sec to 55 m / sec, and the same procedure as in Example 1 was obtained except that the resin fine particles AB for forming the silica layer were mixed [Toner X2]. [Toner X2] The shape factor (SF) of the resin fine particle AA when attached to the surface of the toner mother particle fine particle A was 1.41. It is reported together with the value of SF in Table 1 described below. 7 parts of [Toner X2] thus obtained and 93 parts of [Carrier] were mixed and stirred to prepare [Developer X2] having a toner concentration of 7% by weight.

Embodiment 3

[0266] In Example 2, [Toner X3] was obtained by the same procedure as in Example 2, except that the silica layer-forming resin particles AA were changed to using the silica layer-forming resin particles BB. [Toner X3] The shape factor (SF) of the resin fine particle BB when attached to the surface of the toner mother particle fine particle A was 1.36. It is reported together with the value of SF in Table 1 described below. 7 parts of [Toner X3] thus obtained and 93 parts of [Carrier] were mixed and stirred to prepare [Developer X3] having a toner concentration of 7% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com