Method for manufacturing micro model of real rock core, and used grinding holder and adhesive

A technology of microscopic model and real rock core, which is applied in grinding holders and adhesives, making high-definition real rock core micromodels, and ultra-thin fields, which can solve the problems of low simulation degree, low imaging resolution, and reduced imaging resolution, etc. problem, to achieve the effect of clear boundary and high imaging definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

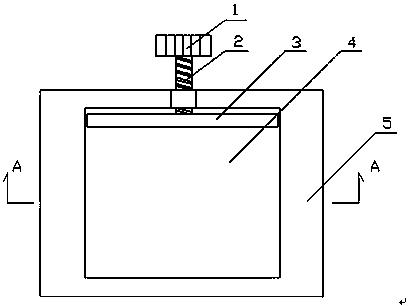

[0031] The real rock core micro model making method comprises the following steps:

[0032] 1) Select the cylindrical core for the experiment, measure and record the permeability and porosity;

[0033] 2) Put the core into a glass tube, add an appropriate amount of rosin, and heat (>180°C) to saturate for 10 hours;

[0034] 3) Cool at room temperature, cut the core into 2~3mm thin slices with a diamond core slicer, smooth and clean the surface of the core, and do grinding pretreatment;

[0035] 4) After mixing cyanoacrylate and rosin in a ratio of 1:1, the core slices are glued and fixed on the chrome glass;

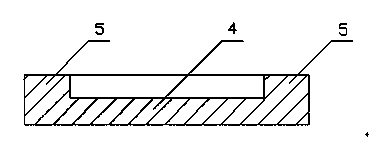

[0036] 5) Fix the chrome glass with the core slice attached to the grinding holder, grind the surface of the slice, first use coarse emery to rough grind on the grinder, and grind the specimen to a thickness of about 200 μm. After that, finely grind with fine emery to smooth and polish the surface. When the fine grinding reaches about 80μm~150μm, the sample is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com