Friction nanometer generator

A nano-generator, friction layer technology, applied in the direction of triboelectric generators, etc., can solve the problems such as the inability to realize automatic separation and contact, the limitation of the range of receiving external mechanical energy, and the complex structure of the generator, which is beneficial to popularization and application, simplification Structure and preparation process, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

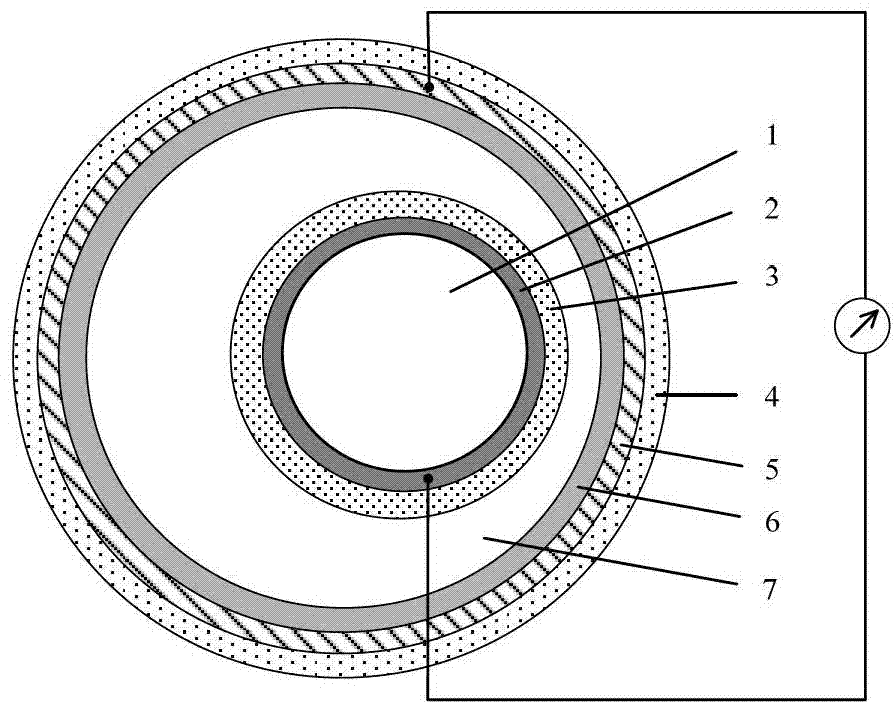

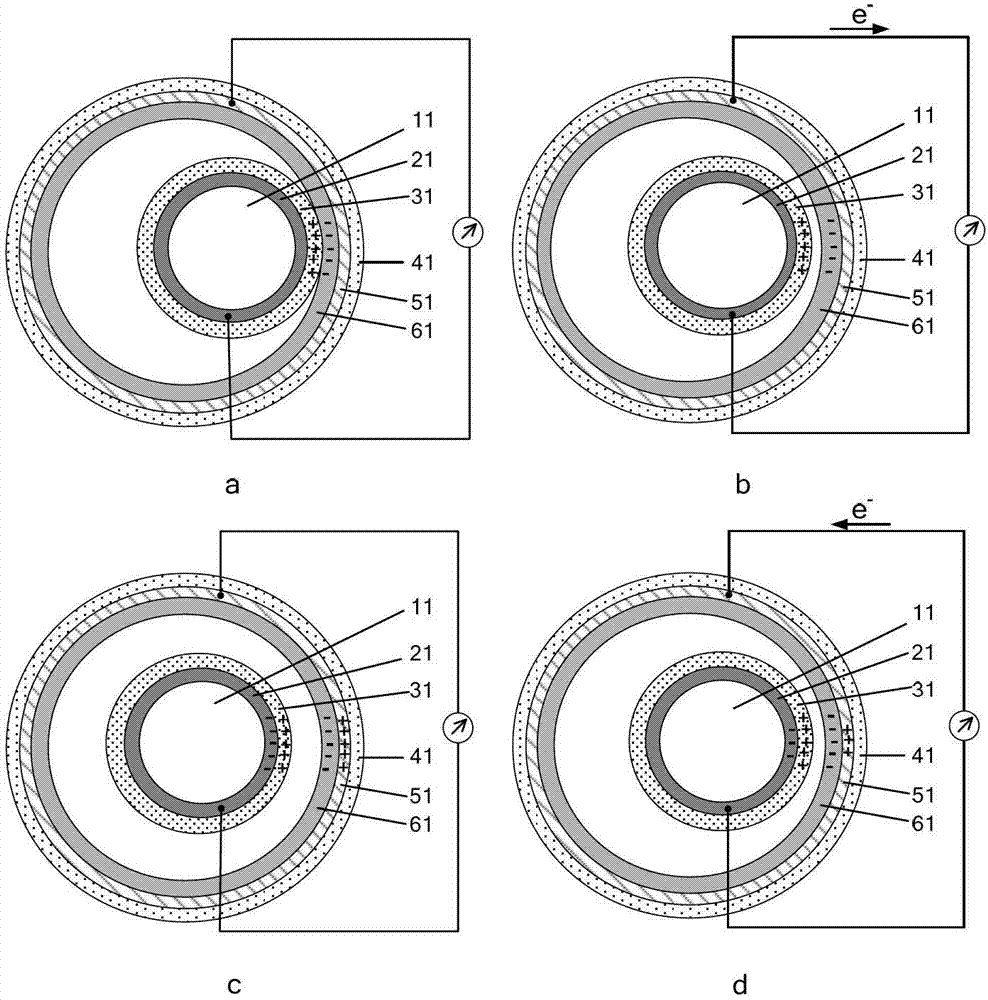

[0068] see figure 1 , a typical basic structure of the triboelectric nanogenerator of the present invention includes a casing and a core body, wherein the core body sequentially includes: an inner core 1, a first conductive layer 2 attached to the outer surface of the inner core 1 And the first friction layer 3 arranged in contact with the outer surface of the first conductive layer 2, the outer surface of the first friction layer 3 faces the cavity 7 of the housing; the housing includes in turn from the outside to the inside: the shell 4, attached to The second conductive layer 5 on the inner surface of the housing 4 and the second friction layer 6 are provided in contact with the inner surface of the second conductive layer 5 , and the inner surface of the second friction layer 6 faces the cavity 7 . The triboelectric nanogenerator structure also includes electrode lead wires that are necessarily related to the triboelectric nanogenerator structure, and are used to lead out ...

Embodiment 2

[0092] In the first embodiment, the first friction layer 3 and the second friction layer 6 of the triboelectric nanogenerator are continuous structures, and the difference between this embodiment and the first embodiment is only that the first friction layer and the second friction layer have at least One is a discontinuous structure, that is, the first friction layer includes a plurality of first friction units that are not connected to each other, and / or the second friction layer includes a plurality of second friction units that are not connected to each other. The materials of each part of the generator can be exactly the same as those in the first embodiment.

[0093] In the present invention, the first conductive layer is the electrode layer of the first friction layer, and the second conductive layer is the electrode layer of the second friction layer. Therefore, in this embodiment, the first friction layer includes Correspondingly, the first conductive layer also inclu...

Embodiment 3

[0103] In the second embodiment, the movement of the core in the casing is not restricted, and can move in any direction in three-dimensional space. The difference between this embodiment and the second embodiment is that the core can only move in one dimension in the housing. The materials of each part of the generator can be exactly the same as those in the first or second embodiment.

[0104] see Image 6 , the generator includes a shell and a core placed in the cavity of the shell, wherein the inner core 14 of the core is a cylinder, and the upper and lower surfaces of the inner core 14 are respectively provided with first conductive units 241 and 242. The first friction units 341 and 342 are arranged in contact with the conductive units 241 and 242 respectively; the structure surrounded by the inner surface of the shell 44 of the housing is also a cylinder, and the second conductive units are respectively arranged on the upper and lower bottom surfaces of the inner surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com