Split combined plastic hanger

A combination and plastic frame technology, applied in the field of daily necessities, can solve the problems of poor work safety and reliability, and difficulty in guaranteeing normal working life, and achieve the effect of ensuring normal working life, significant economy, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

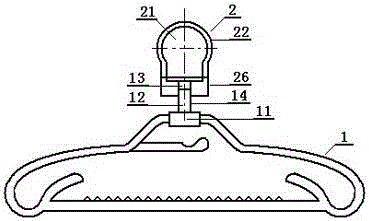

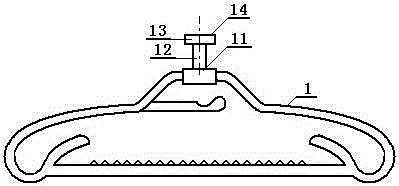

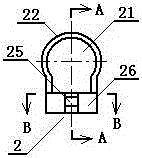

[0019] exist figure 1 , figure 2 , image 3 with Figure 4 Among them, the main body of the split combined plastic clothes hanger of the present invention is composed of a frame body 1 and a hook 2. The split type is formed by holding, wherein: the frame body 1 is fixed on the hook setting position 11 with a T formed by interconnecting the vertical rod 12 and the convex chuck 13 coaxially arranged on the top end of the vertical rod 12. Type hanging rod 14; the main body of the hook 2 is L-shaped, with a straight hanging end 22 provided with a closed hanging hole 21 and a convex-shaped clip on the T-shaped hanging rod 14. The head 13 and the vertical rod 12 correspond to the movable extensions, and are formed by the horizontal hanging end 26 of the buckle hole 25 formed by the horizontal stepped counterbore 23 and the vertical guide groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com