Machine tool working condition real-time monitoring system based on wireless sensor network

A wireless sensor, real-time monitoring technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of less data parameters, affecting the working stability of machine tools, motor life, and impact on machine tool production, etc., to achieve comprehensive monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples.

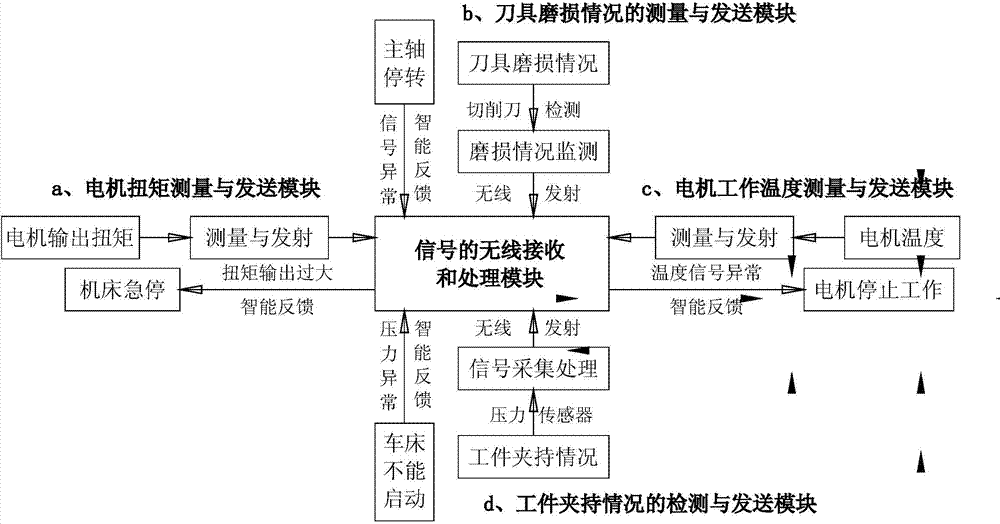

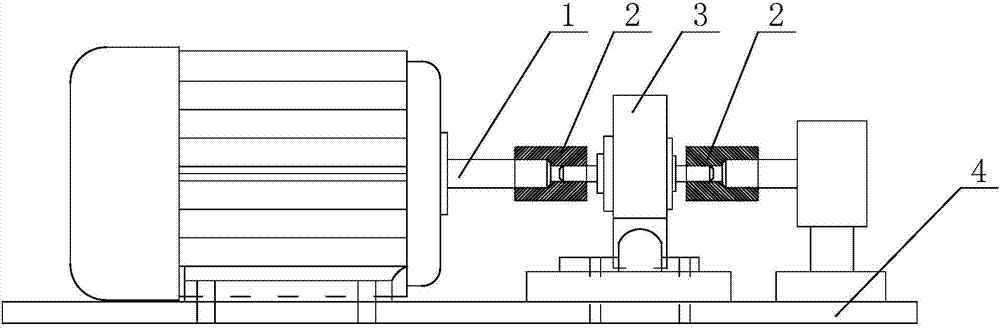

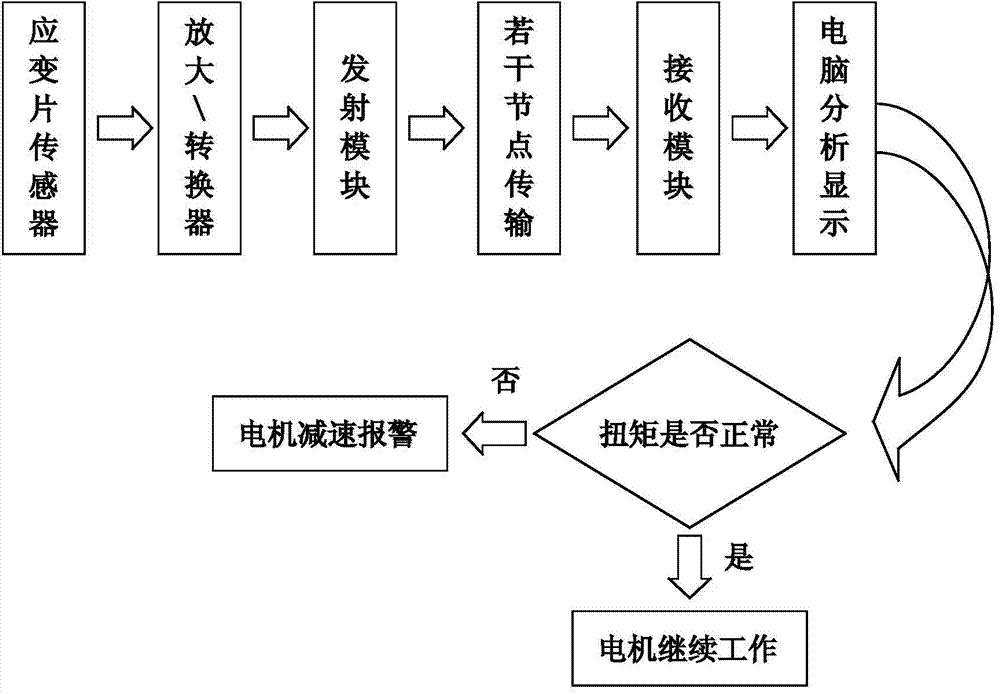

[0029] exist figure 1 , figure 2 , image 3 In the first embodiment shown, the measurement of the machine tool motor torque is carried out with the strain-type wireless torque sensor as the core component, and its main structure is to add a wireless transmission module on the basis of the dynamic torque sensor. The resulting strain-type wireless torque sensor is small in size and simple in structure, has the same characteristics as a dynamic torque sensor, and can convert the collected non-electricity signal into an electric quantity signal, and then transmit the signal wirelessly to the network node through single-chip processing and control place. The torque signal is transmitted between the nodes, and finally reaches the host computer terminal. The upper computer will use relevant software to reflect the signal in the form of a graph, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com