Injection device for injection molding machines

A technology of injection device and injection molding machine, applied in the field of mechanical industrial equipment, can solve problems such as single structure, no heat preservation device, cumbersome work, etc., and achieve the effect of easy application in production, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

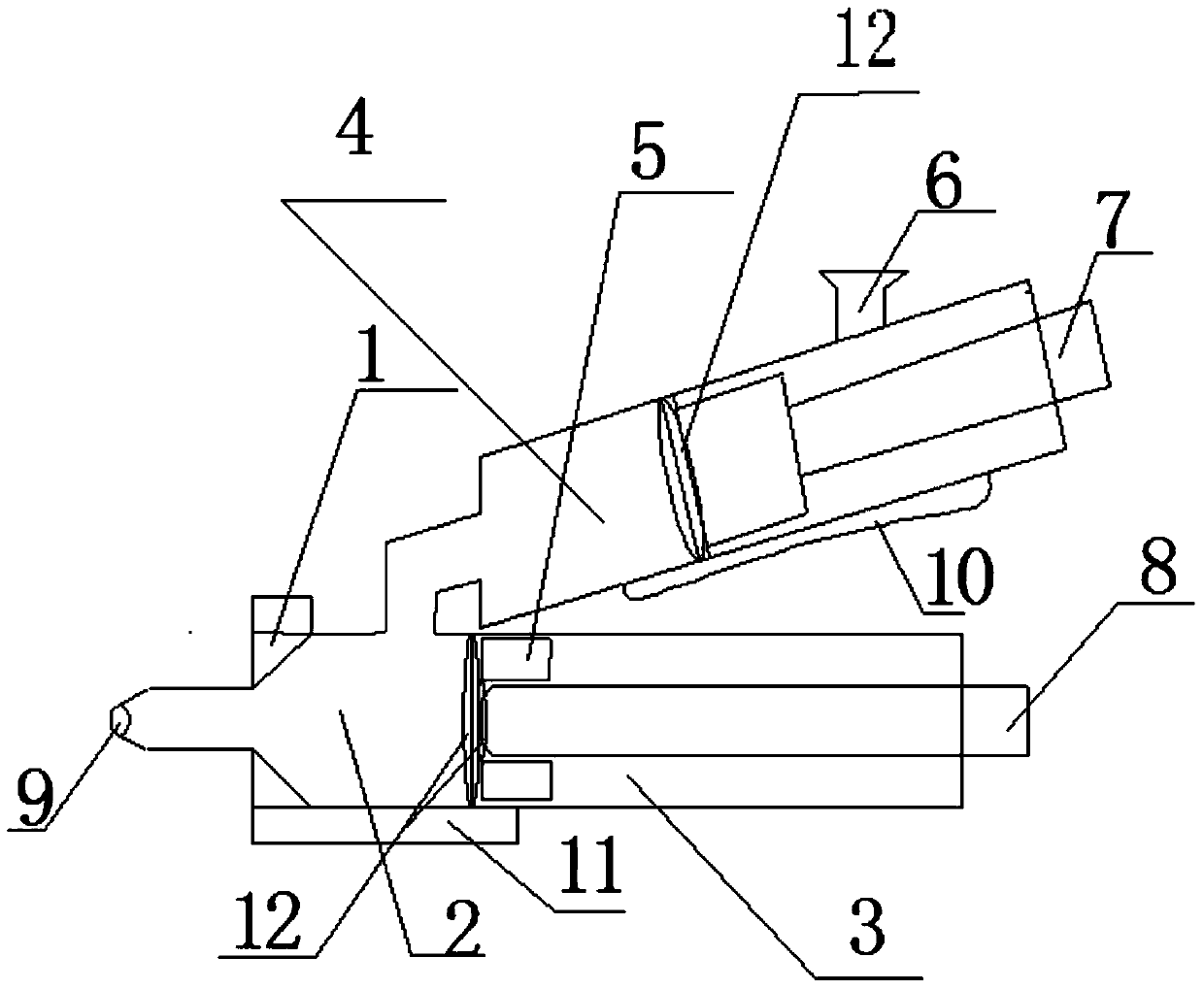

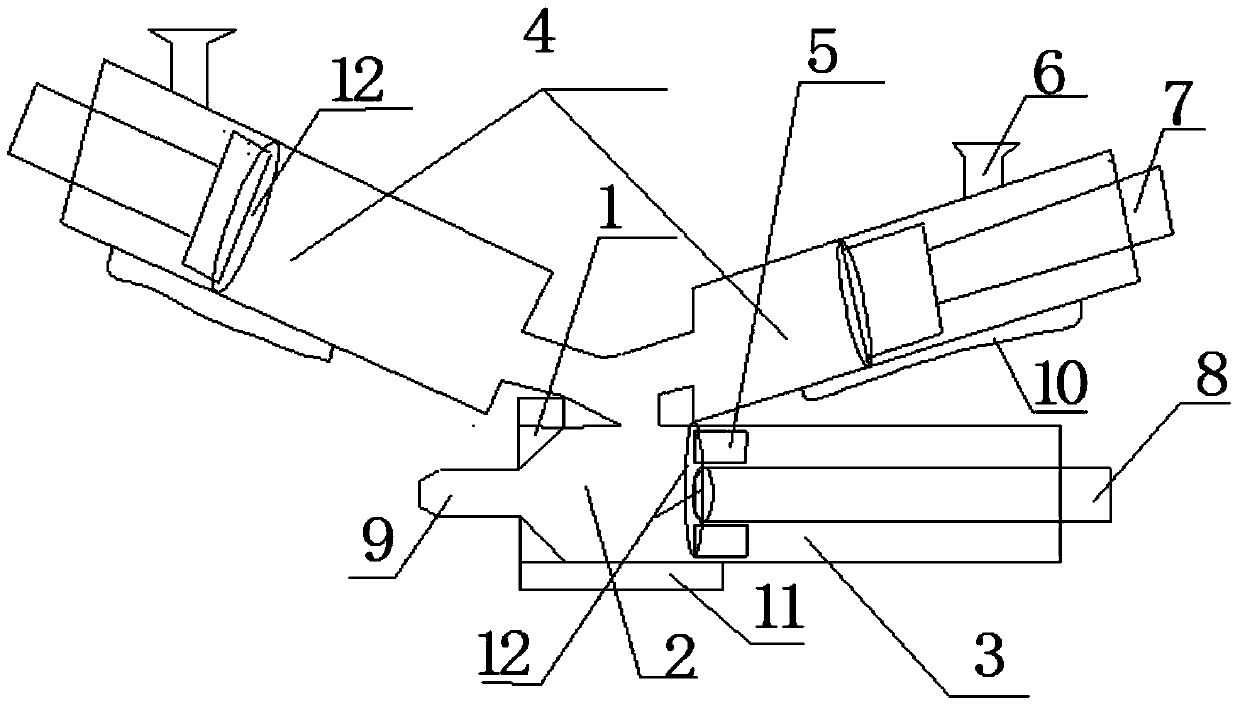

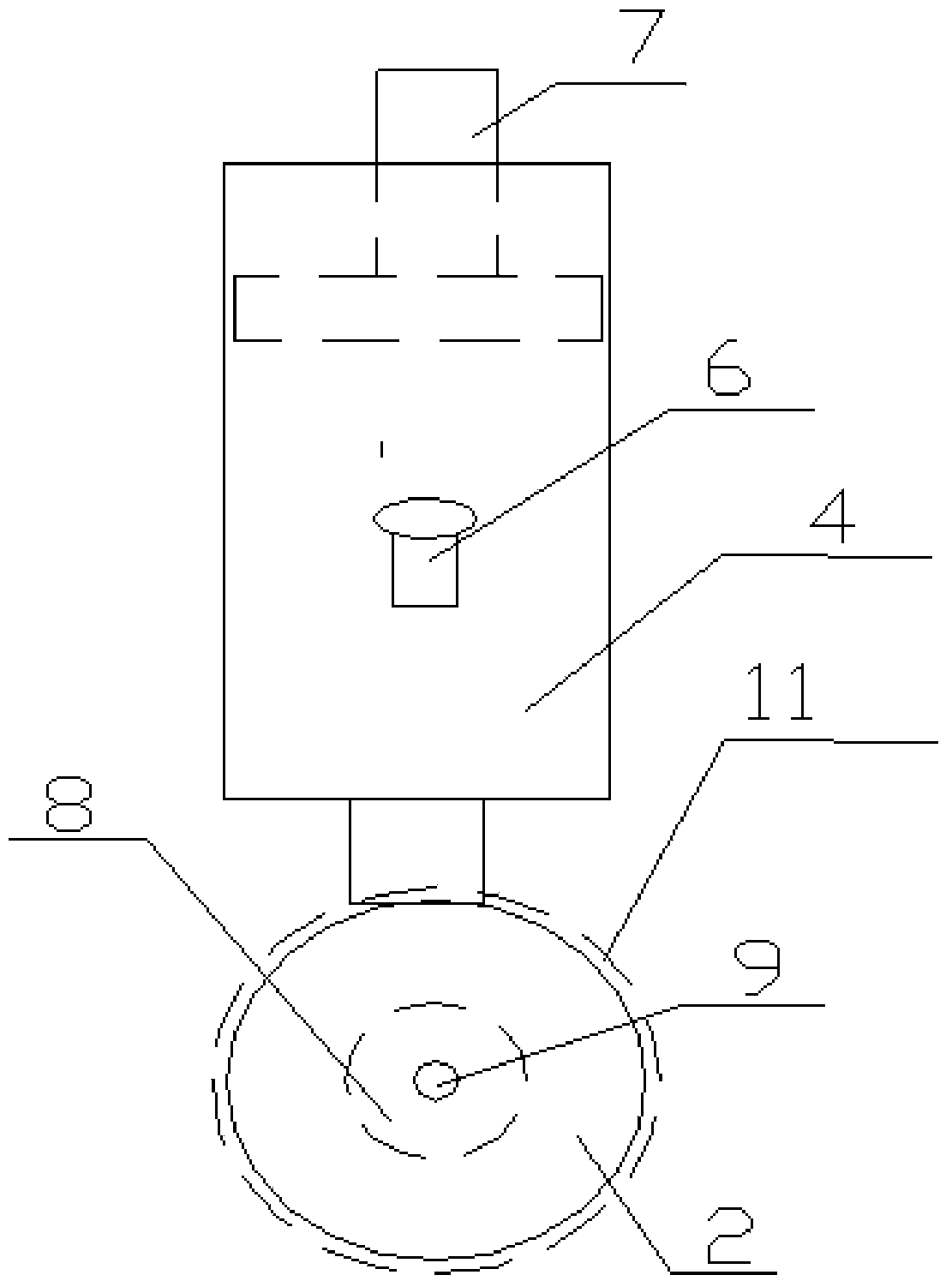

[0015] Such as figure 1 As shown, an injection device of an injection molding machine includes a connecting body 1, a storage cylinder 2 and an injection barrel 3, and one end of the connecting body 1 is connected to the storage cylinder 2, as figure 2 The upper part of the shown storage cylinder 1 is provided with several feed cylinders 4, the inside of the storage cylinder 2 and the supply cylinder 4 are all equipped with pusher pistons 5, and the top of the storage cylinder 4 is provided with a feeding port 6 , the feeding cylinder 4 is provided with a feeding screw 7, the storage tank 2 is connected with the injection cylinder 3, the injection cylinder 3 is provided with an injection screw 8, and the other end of the connecting body 1 is connected with Nozzle 9, such as image 3 The nozzle 9 shown is circular and has a diameter of 50mm-100mm. It is equipped with a material storage cylinder 2 to prepare for loading raw materials befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com