A combined stacking die head for a film blowing machine

A combined type, film blowing machine technology, applied in the field of die head, can solve the problems of uneven plasticization time of molten plastic, short plasticization time of molten plastic, poor quality of extruded film, etc., to extend the length and extend the plasticization time , uniform plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

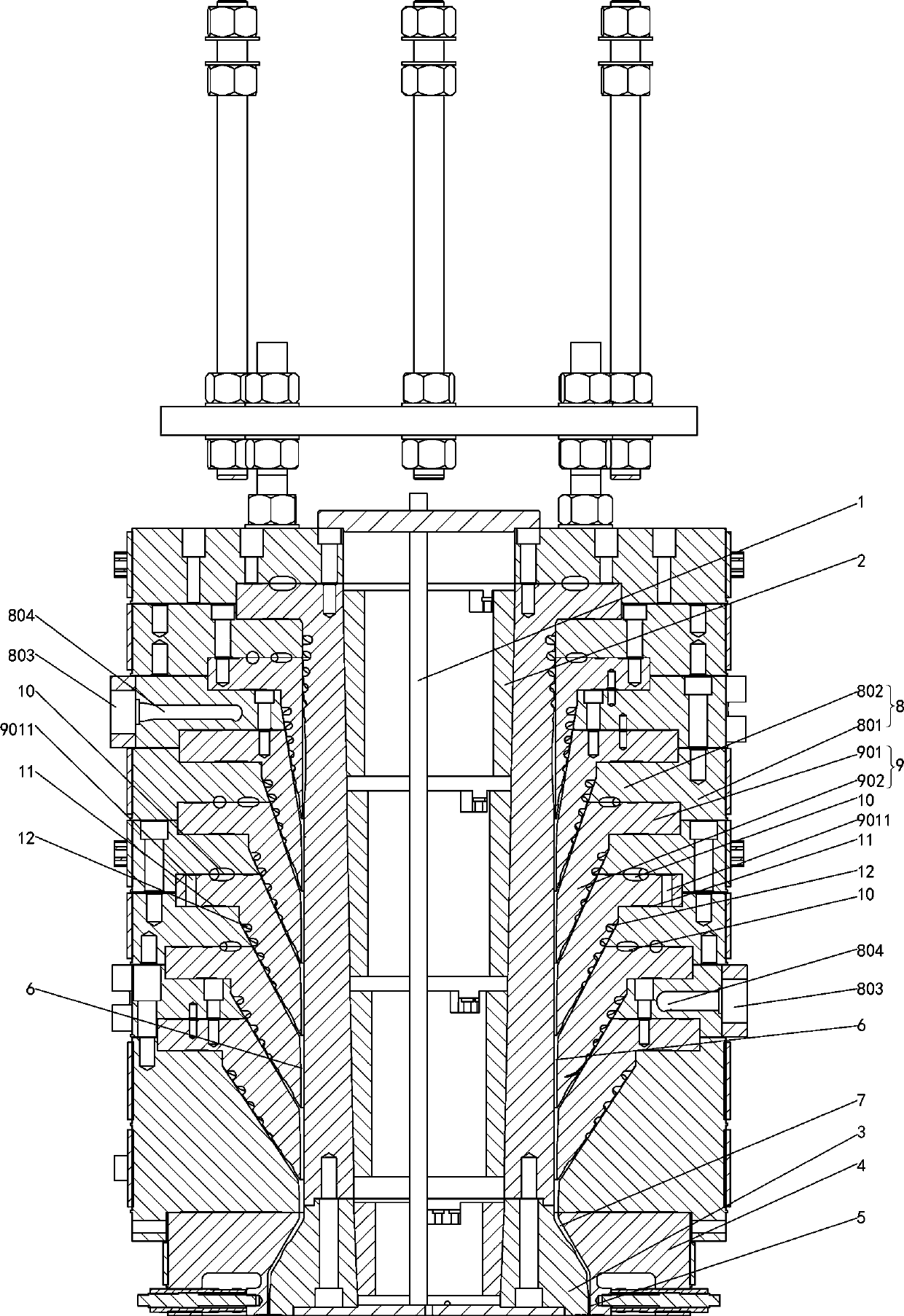

[0011] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0012] Such as figure 1 As shown, a combined superimposed die head of a film blowing machine includes an air pipe 1, a mandrel 2, a plurality of runner seats, a core nozzle 3 and a die lip ring 4, the air pipe 1 is arranged in the mandrel 2, and each flow The channel seat is stacked on the outside of the mandrel 2 from bottom to top, the core mouth 3 is set at the lower end of the mandrel 2, the die lip ring 4 is set at the lower end of the bottom runner seat, the mold core mouth 3 and the die lip ring 4 The die mouth 5 is formed, and a secondary flow channel 6 is provided between each flow channel seat and the mandrel 2, and a main flow channel 7 is provided between the mold core mouth 3 and the die lip ring 4, and each secondary flow channel 6 merges into the main flow channel 7 The starting end, the end of the sprue 7 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com