Ink pot device

A technology of ink pots and inks, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as difficult cleaning and ink residue, and achieve the effect of improving reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the inkpot device according to the present invention will be described in detail with reference to the accompanying drawings. In the following embodiments, although various limitations are made to constituent elements, types, combinations, shapes, relative arrangements, etc., these are merely examples. For example, the present invention is not limited thereto.

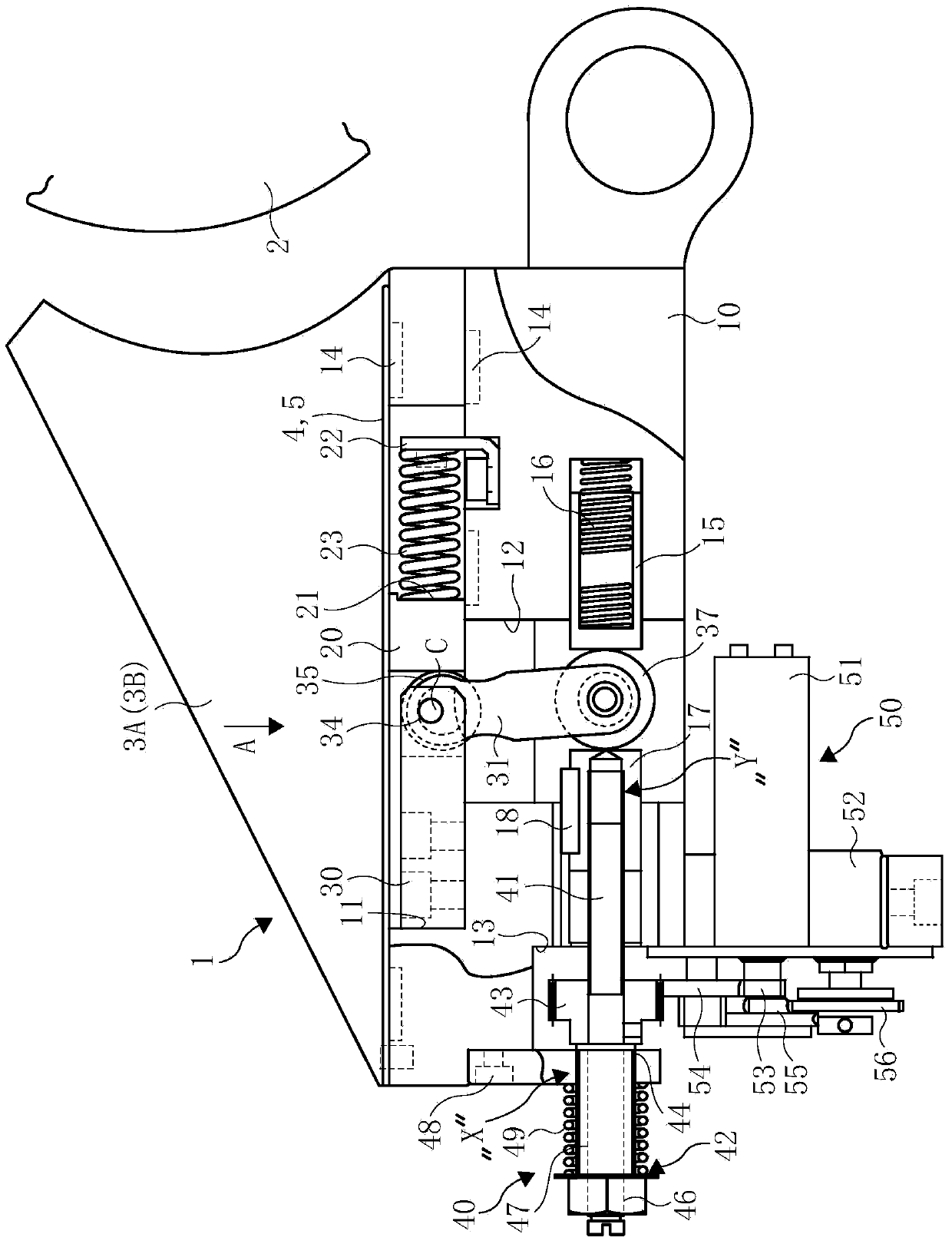

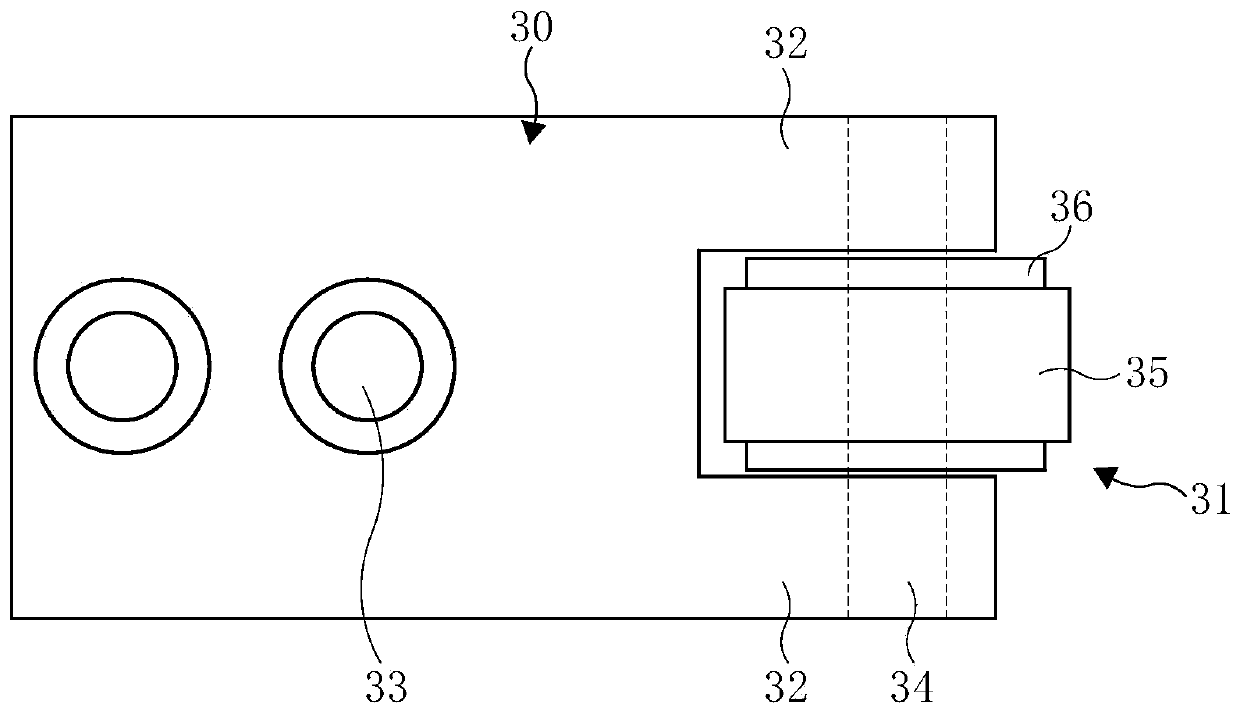

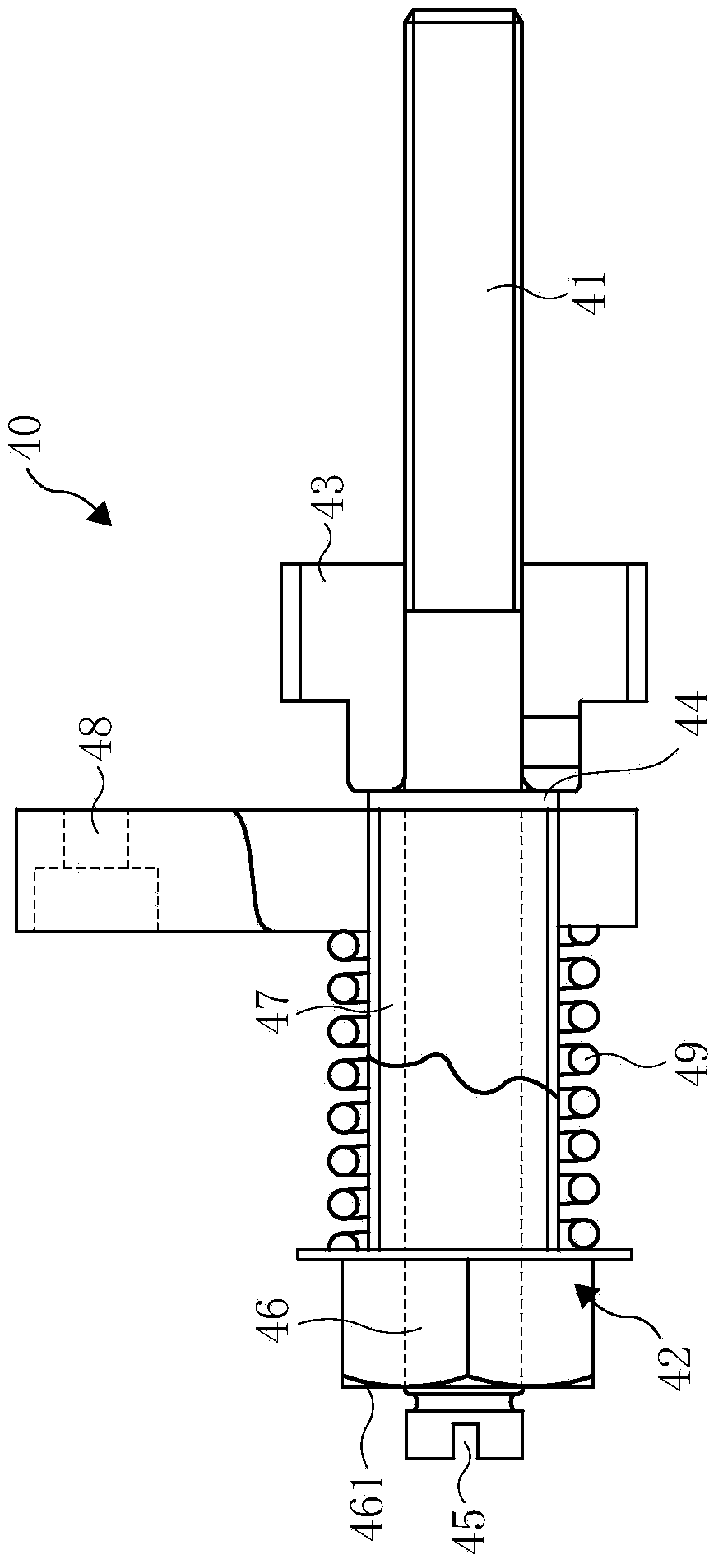

[0066] figure 1 The shown ink pot device 1 is composed of an ink main roller 2 pivotally supported on the frame of a printing machine not shown in the figure, a rectangular parallelepiped ink pot body 10 having approximately the same length as the ink main roller 2, and disposed on the main body 10. The ink baffles 3A and 3B on the two sides above and the two cover plates 4 and 5 covering the body 10 are composed of the main ink roller 2 as the front, the cover plate 5 as the bottom surface, and the ink baffles 3A and 3B as the bottom surface. The two sides are surrounded to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com