Semi-automatic chopstick packaging device

A kind of packaging equipment, semi-automatic technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost and low efficiency, achieve low manufacturing and maintenance costs, not easy to damage, reduce labor costs and external processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The equipment described in the present invention will be further described with more specific examples below in conjunction with the accompanying drawings.

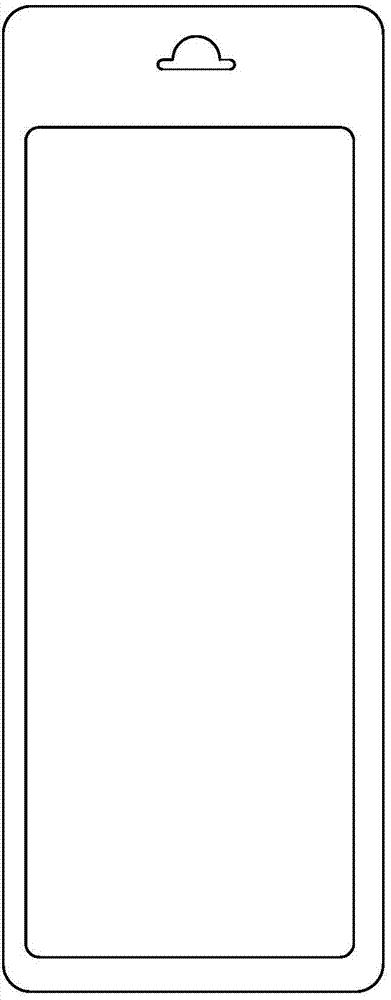

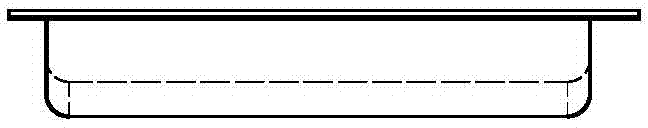

[0034] refer to Figure 1-3 , the figure shows the specific structure of a chopsticks packaging box processed by the equipment of this example, including a plastic box body and cardboard. The plastic box body includes two parts, the main body and the edge. The main body is a groove structure, and the edge circles around the main part . The plane outline size of the plastic box body is the same as that of the cardboard. The cardboard cover is on the open side of the groove structure on the plastic box body. The part of the cardboard contacting the edge of the plastic box body is bonded together with the edge of the plastic box body by means of heat sealing.

[0035] With reference to the accompanying drawings, the various components of the equipment shown in this example are in a linear layout, the frame 24 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com