Multilayer vesicular mesoporous silicon dioxide with adjustable number of layers and synthetic method thereof

A technology of mesoporous silica and multi-layer vesicles, applied in the directions of silica, silica, pharmaceutical formulations, etc., can solve the problem of uneven particle size distribution, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

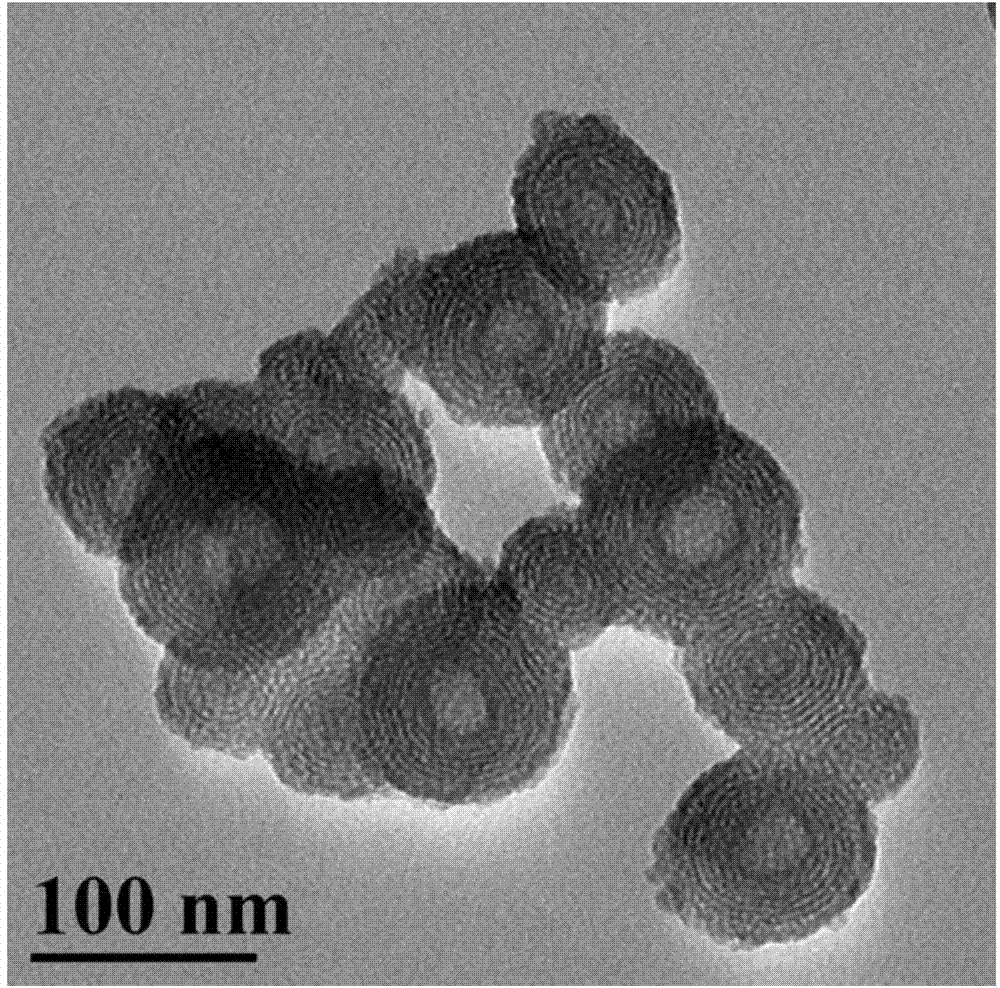

[0027] Put a 100mL beaker on a magnetic stirrer, add 35mL distilled water and heat up to 30°C, add 0.142g CTAB to the distilled water under stirring, stir to form a transparent solution, add DDAB with a molar ratio of 1:0.625 to CTAB, and stir After completely dissolving, add 0.69ml of ammonia water, take 2.0g of TEOS and slowly drop into the solution under stirring after 2h, seal and stir for 24h at constant temperature. The obtained white precipitate solution was transferred to a 50ml reaction kettle, and placed in a thermostat at 100°C for 24 hours. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 50° C. for 12 hours, and then the precipitate was calcined in a tubular calciner at 550° C. for 6 hours to obtain vesicular mesoporous silica with 7 layers.

Embodiment 2

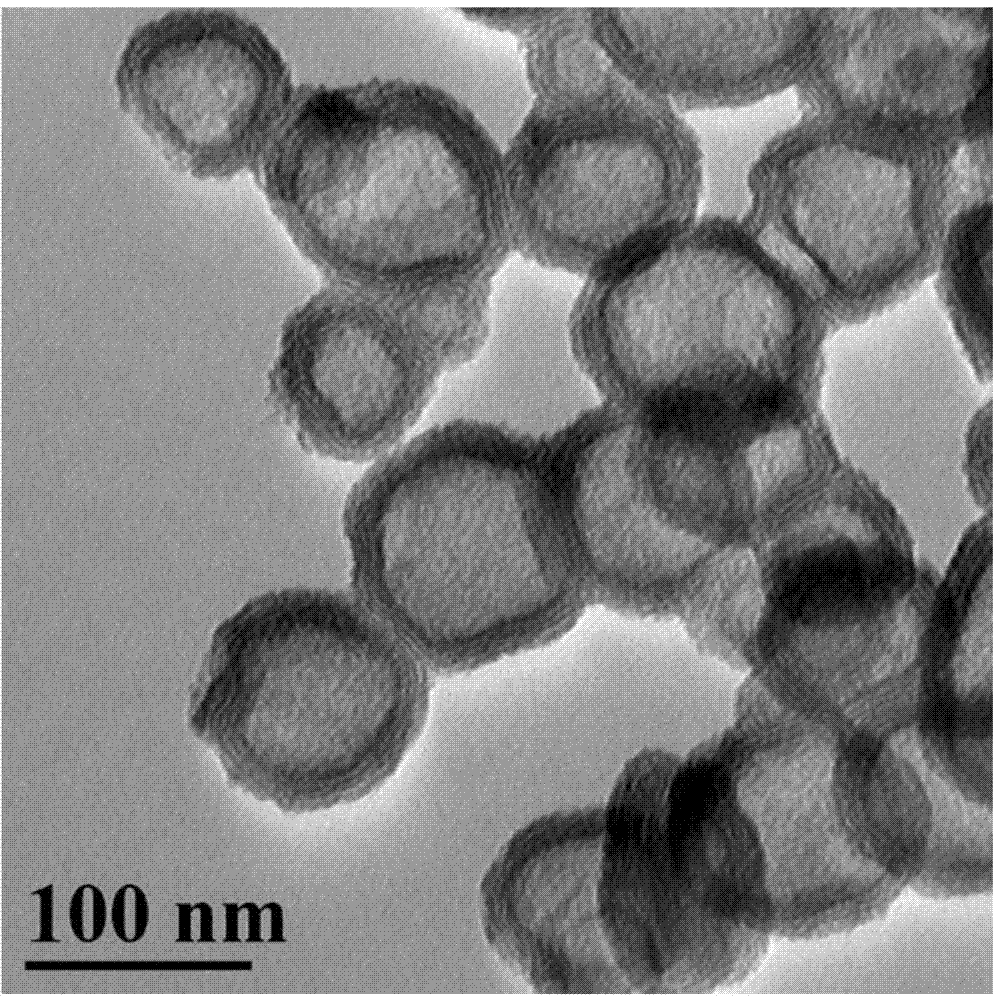

[0029] Put a 100mL beaker on a magnetic stirrer, add 35mL distilled water and heat up to 30°C, add 0.142g CTAB to the distilled water under stirring, stir to form a transparent solution, add DDAB with a molar ratio of 1:0.823 to CTAB, and stir After completely dissolving, add 0.69ml of ammonia water, take 2.0g of TEOS and slowly drop into the solution under stirring after 2h, seal and stir for 24h at constant temperature. The obtained white precipitate solution was transferred to a 50ml reaction kettle, and placed in a thermostat at 100°C for 24 hours. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 50° C. for 12 hours, and then calcined in a tubular calciner at 550° C. for 6 hours to obtain vesicular mesoporous silica with 4 layers.

Embodiment 3

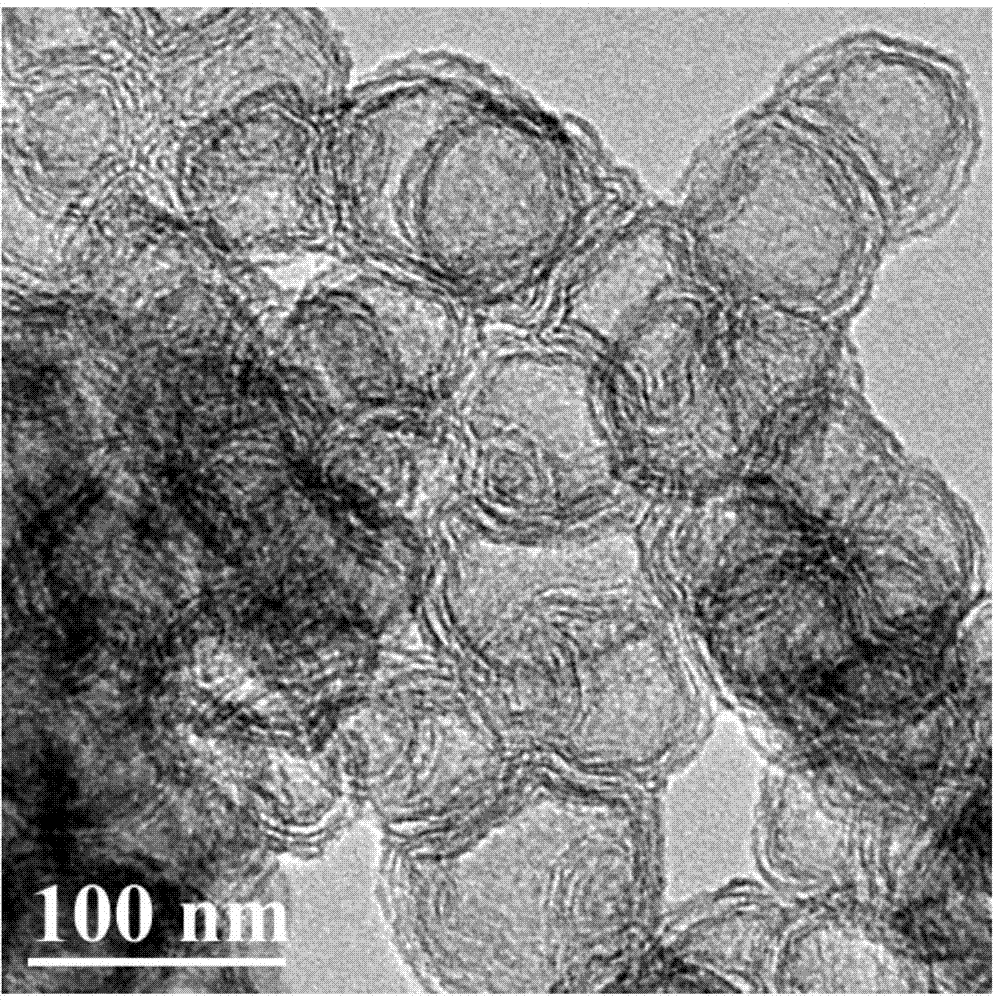

[0031] Put a 100mL beaker on a magnetic stirrer, add 35mL distilled water and heat up to 30°C, add 0.142g CTAB to the distilled water under stirring, stir to form a transparent solution, add DDAB with a molar ratio of 1:1.104 to CTAB, and stir After completely dissolving, add 0.69ml of ammonia water, take 2.0g of TEOS and slowly drop into the solution under stirring after 2h, seal and stir for 24h at constant temperature. The obtained white precipitate solution was transferred to a 50ml reaction kettle, and placed in a thermostat at 100°C for 24 hours. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 50°C for 12 hours, and then the precipitate was calcined in a tubular calciner at 550°C for 6 hours to obtain vesicular mesoporous silica with 2-3 layers.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap