Code disc retaining nut for photoelectric encoder

A photoelectric encoder, fixing nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems that workers are not easy to master, low axial force capacity, and high cost of parts, and achieves easy popularization and use and high work reliability. , The effect of easy maintenance and replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

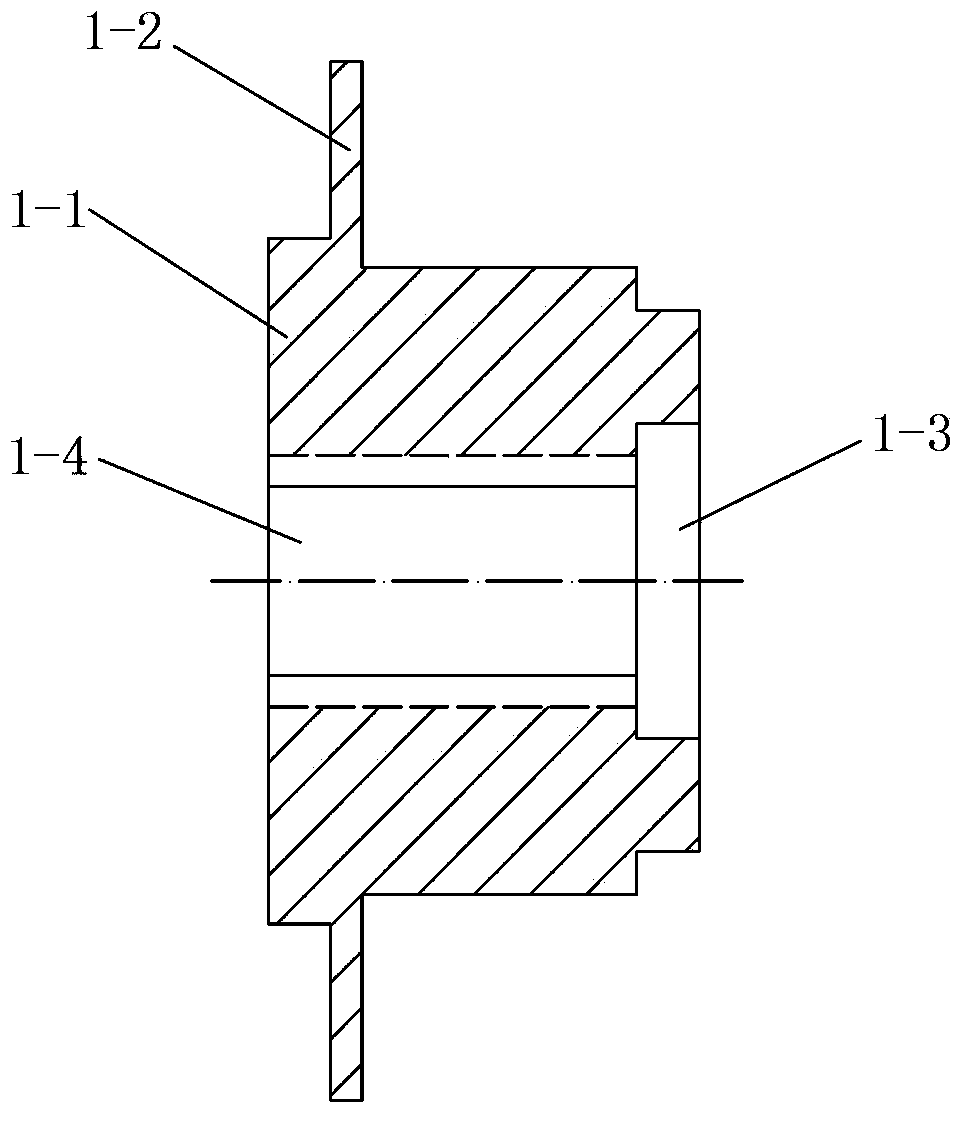

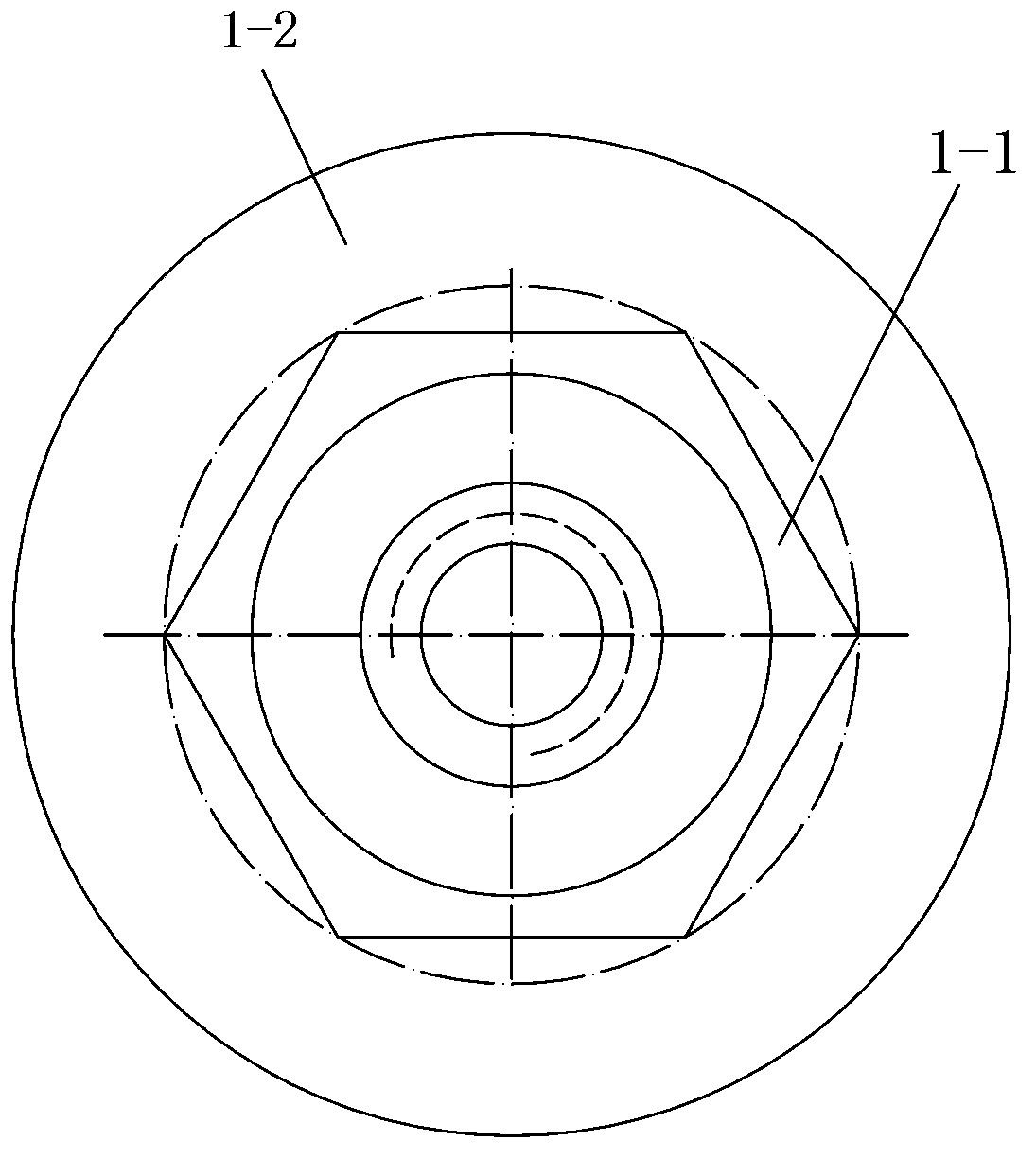

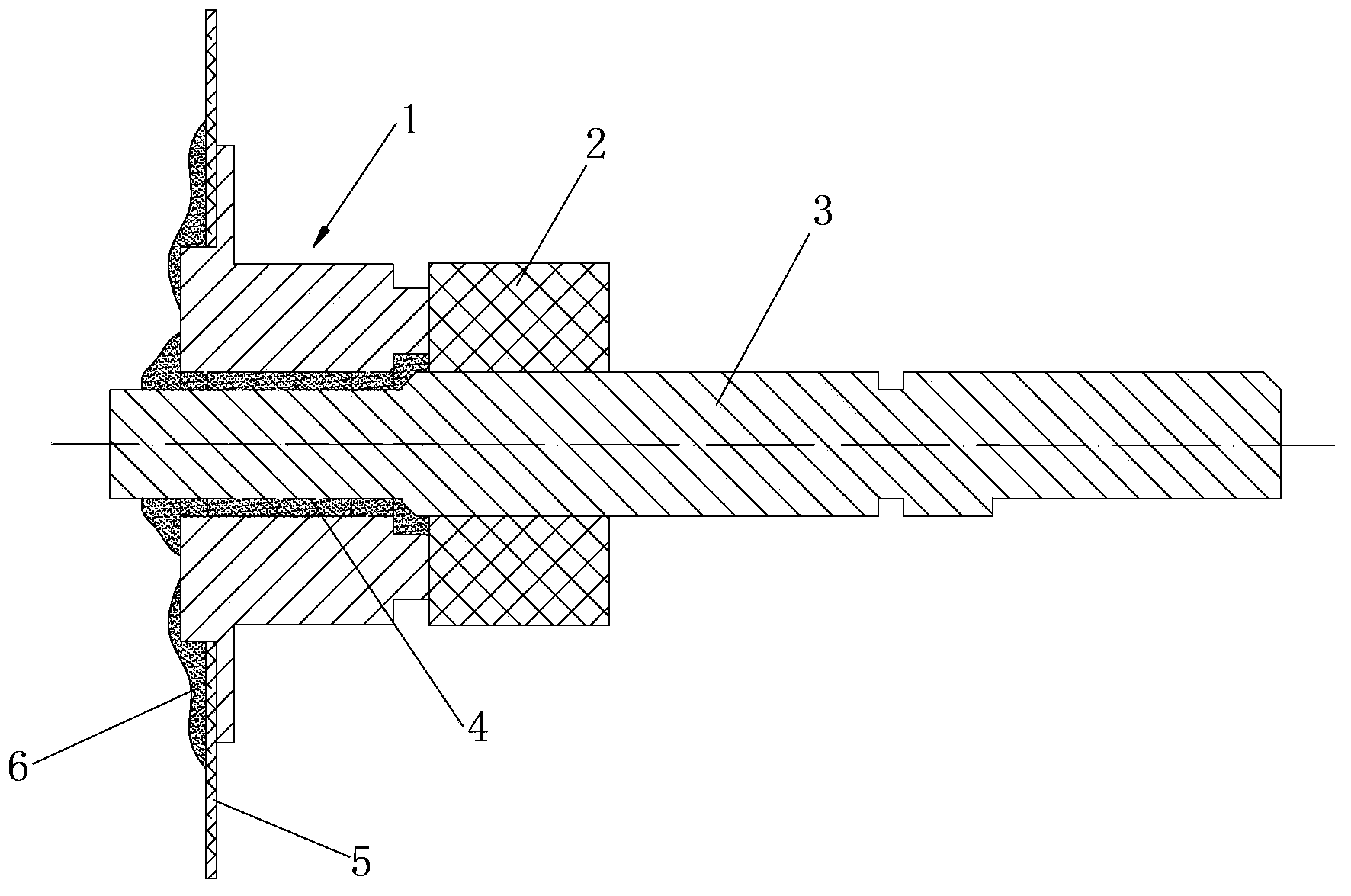

[0023] Such as figure 1 , figure 2 and image 3 A code disc fixing nut for a photoelectric encoder is shown, including a nut body 1-1, and a threaded hole 1-1 for matching with a photoelectric encoder solid shaft 3 is provided on the nut body 1-1 along the direction of its central axis. 4. The code wheel 5 is installed at one end of the nut body 1-1, and one end of the nut body 1-1 is provided with an outer eaves 1-2 for preventing the code wheel 5 from shaking.

[0024] combine figure 1 and figure 2 , the other end of the nut body 1-1 is provided with a glue storage hole 1-3 arranged coaxially with the threaded hole 1-4, the threaded hole 1-4 and the glue storage hole 1-3 are equipped with Connect the thread locking glue 4 of the nut body 1-1 and the solid shaft 3 of the photoelectric encoder. One end of the nut body 1 - 1 is provided with a transparent adhesive 6 for bonding the nut body 1 - 1 to the code wheel 5 . The cross section of the nut body 1-1 is a regular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com