Sampling method for accurately testing performance of silicon steel magnesium oxide coating

A magnesia and silicon steel technology, applied in the field of strip steel coating, which can solve the problems of magnesia powder falling off or scraping off, inaccurate magnesia coating amount and moisture content testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

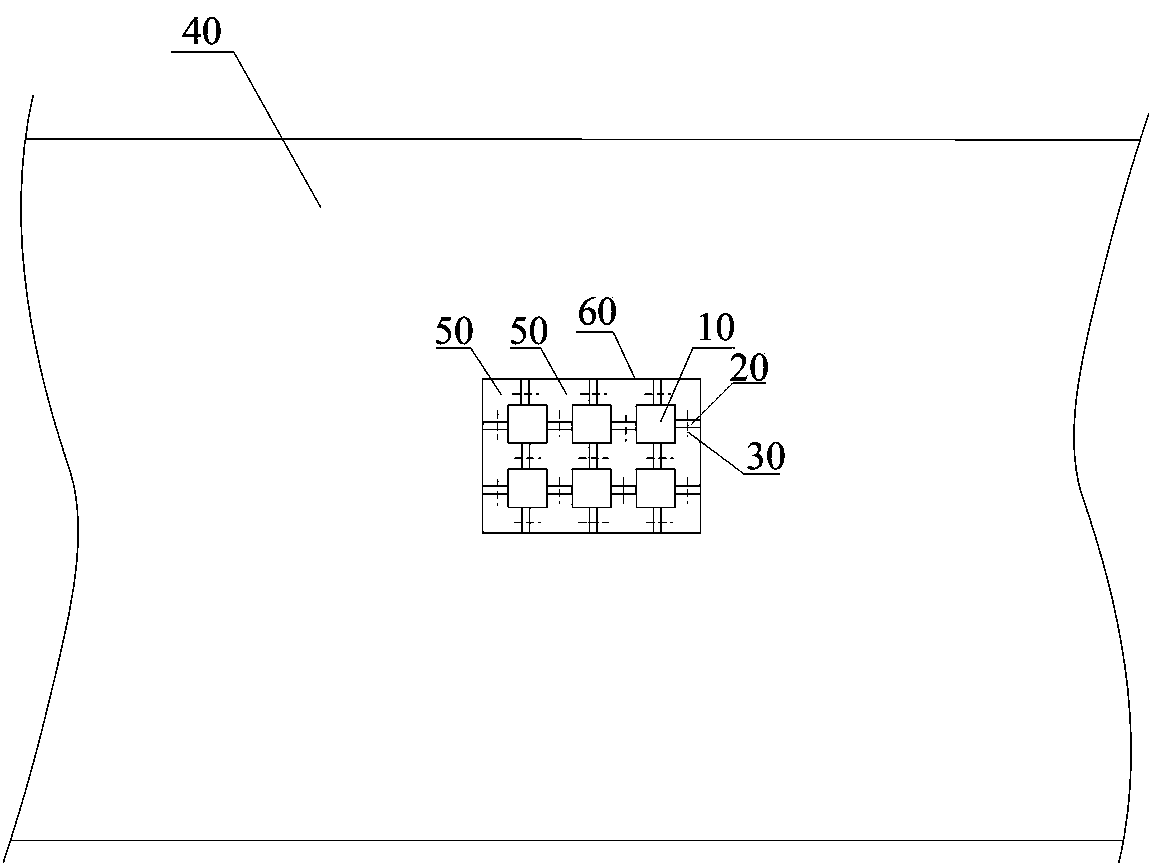

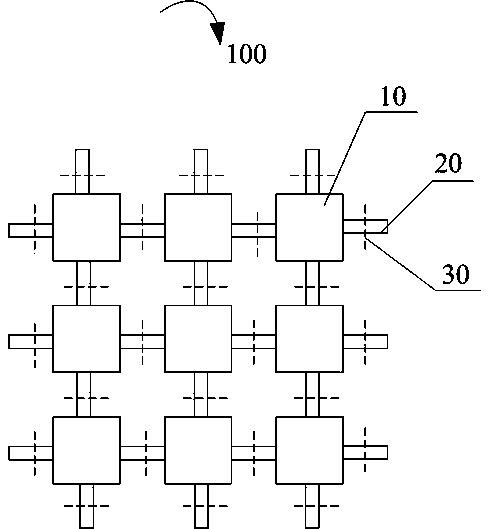

[0030] Such as figure 1 and figure 2 Shown, the present invention provides a kind of sampling method that is used for accurately testing silicon steel magnesia coating performance, and it comprises the following steps:

[0031] 1) Before the silicon steel plate 40 enters the coating machine, a certain area 60 of the silicon steel plate 40 is punched, and the area 60 of the silicon steel plate 40 obtained after part of the steel plate 50 is washed away is divided into a plurality of steel plates 10 to be tested , each steel plate 10 to be tested is connected to the surrounding adjacent steel plates to be tested by a connecting plate 20 to form a whole steel plate to be tested 100 (such as figure 2 shown);

[0032] 2) Carrying out indentation 30 on multiple connecting plates 20;

[0033] 3) Send the steel plate 40 into the coating machine, and apply the magnesium oxide coating liquid to the surface of the silicon steel steel plate 40, that is, the entire surface of the stee...

Embodiment 2

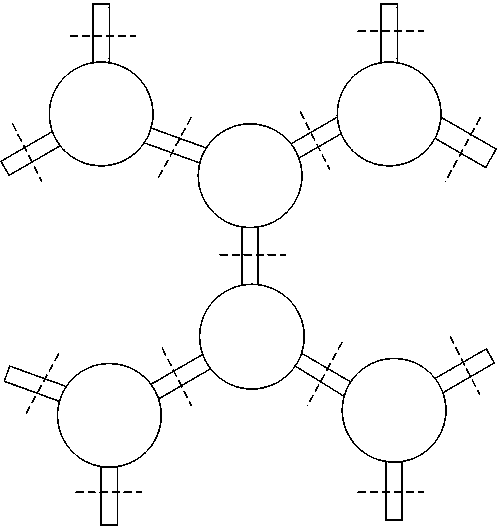

[0039] Such as image 3 As shown, this embodiment is roughly the same as Embodiment 1, except that the shape of each steel plate to be tested is circular. The periphery of each steel plate to be tested is connected with three connecting plates, and an included angle of 120 degrees is formed between two adjacent connecting plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com