CNC Machine Tool Control System with Supportive Redundant Operation Function

A technology of control system and redundant operation, applied in the field of mechanical processing, can solve problems such as failure and inability of CNC machine tools to operate, and achieve the effect of ensuring safe supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

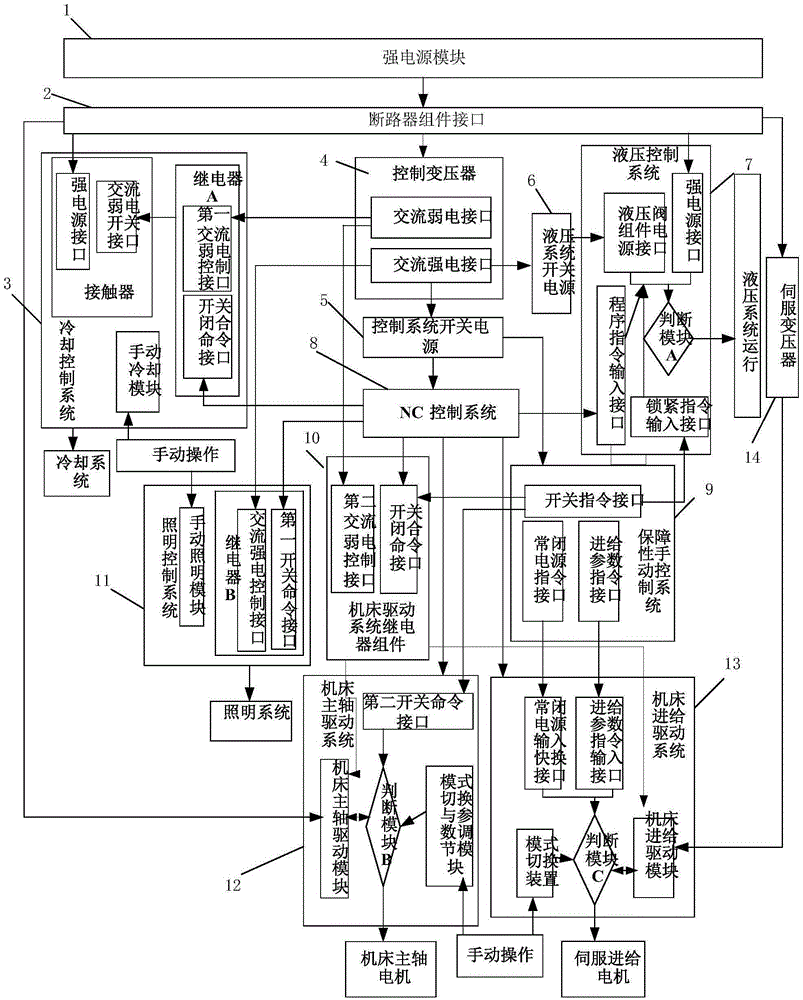

[0027] Referring to the accompanying drawings, the CNC machine tool control system with guaranteed redundant operation function includes: strong power supply module 1, circuit breaker component interface 2, cooling control system 3, control transformer 4, control system switching power supply 5, hydraulic system switching power supply 6. Hydraulic control system 7, numerical control system 8, supportive manual control system 9, machine tool drive system relay assembly 10, lighting control system 11, machine tool spindle drive system 12, machine tool feed drive system 13 and servo transformer 14;

[0028] The cooling control system 3 includes: a relay A, a contactor and a manual cooling module; wherein, the relay A has a first AC weak current control interface and a switch closing command interface; the contactor has an AC weak current switch interface and a strong power supply interface; the first of the relay A The AC weak current control interface is connected to the AC weak cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com