Front-maintenance type infrared electronic whiteboard

An electronic whiteboard and front-maintenance technology, which is applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as weak connection, lack of aesthetic feeling, troublesome users on site, etc., and achieve a firm and reliable connection structure, The effect of flexible and changeable color and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in the following embodiments in conjunction with the accompanying drawings.

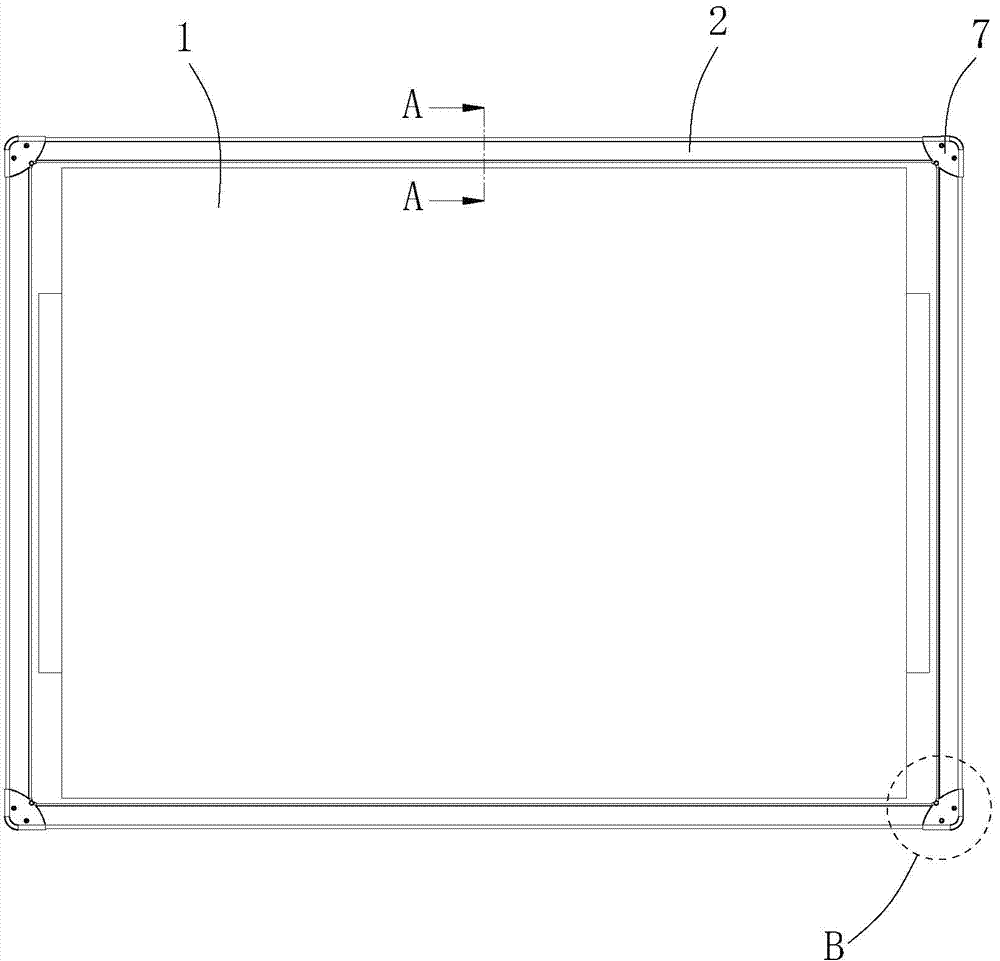

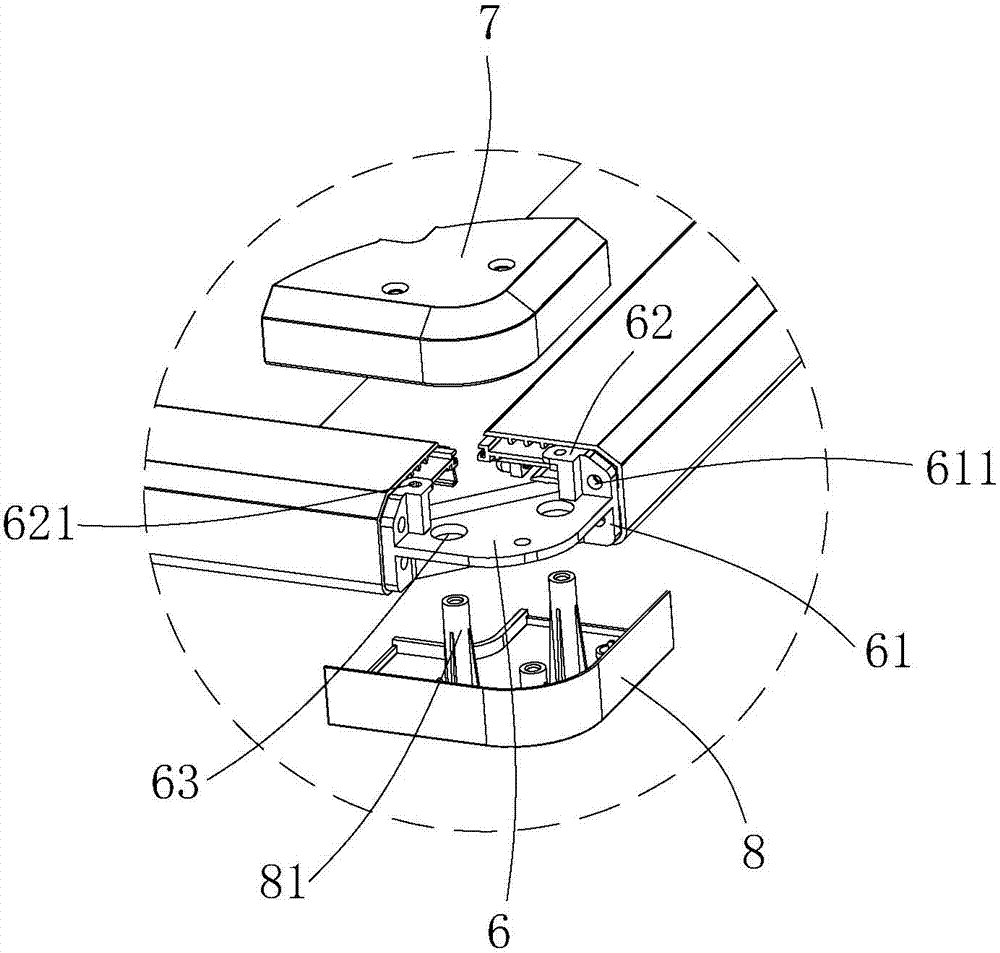

[0026] like Figure 1 to Figure 6 As shown, a front-maintenance infrared electronic whiteboard includes a whiteboard body 1 and four frames 2 installed on the edge of the whiteboard body 1. The frame 2 is made of an aluminum alloy extrusion die, and its surface can be made Powder coated, oxidized or brushed.

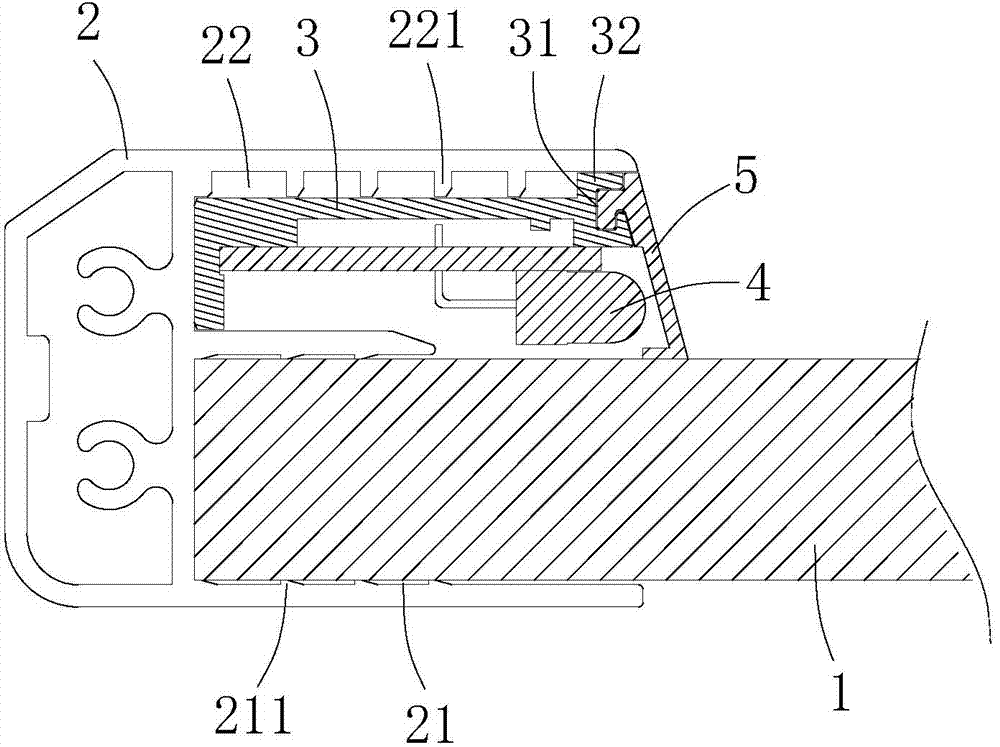

[0027] Each frame 2 is provided with a first card slot 21 and a second card slot 22 , and the first card slot 21 is located at the rear end of the second card slot 22 for fitting the whiteboard body 1 . In order to prevent the whiteboard body 1 from loosening, the inner wall of the first locking slot 21 is provided with a plurality of tooth-shaped locking positions 211 for restricting the whiteboard body 1 . A PCB fixing strip 3 is set inside the second card slot 22 , and an infrared PCB circuit board 4 and a filter strip 5 are fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com