Method and device for arranging passing holes in single plate

A via hole and single board technology, applied in the electronic field, can solve the problems of easy omission and error, increase the design cycle of PCB single board, and affect the quality of high-speed wiring signal transmission, so as to improve design efficiency and reduce high-speed signal impedance discontinuity The effect of improving the quality of signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

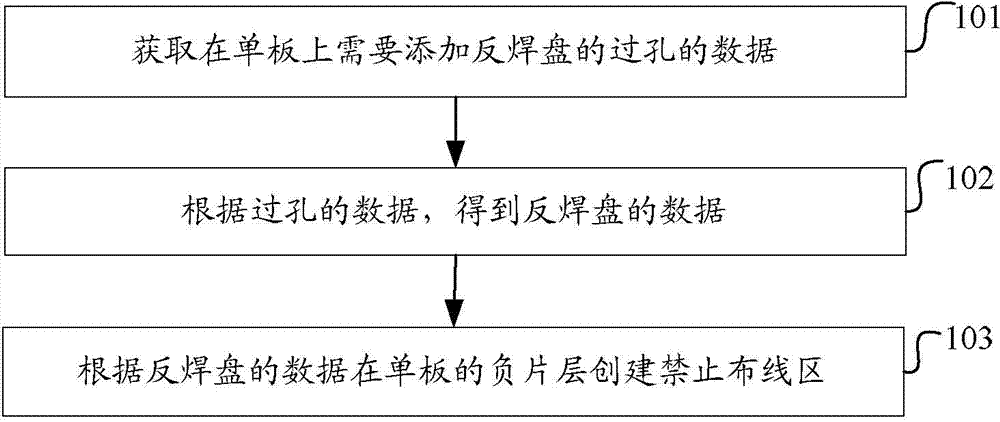

[0039] Embodiment 1, a method for setting vias on a single board, such as figure 1 shown, including:

[0040] Step S101: Obtain the data of the via holes on the single board that need to add anti-pads;

[0041] In an implementation manner of this embodiment, step S101 may specifically include:

[0042] Obtain the via information of all high-speed signal differential traces on the board;

[0043] Vias are highlighted for all high-speed signal differential traces.

[0044] Get the selected via in the highlighted via as the via to which the antipad needs to be added.

[0045] In other implementation manners, via holes that meet other predetermined conditions may also be used as via holes that need to be added with anti-pads.

[0046] Step S102: Obtain the data of the anti-pad according to the data of the via hole;

[0047] The data of the via hole may include, but is not limited to: the coordinates of the via hole, the radius of the via hole, and the like.

[0048] Optional...

Embodiment 2

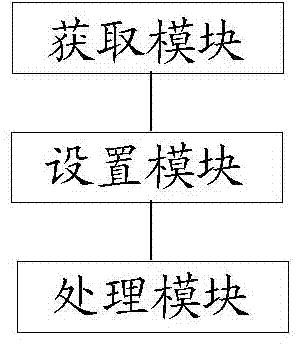

[0056] Embodiment 2, a device for setting via holes on a single board, such as figure 2 As shown, the device includes:

[0057] The acquisition module is used to acquire the data of the via holes that need to add anti-pads on the single board;

[0058] A setting module, configured to set the data of the anti-pad according to the data of the via hole;

[0059] The data of the via hole may include, but is not limited to: the coordinates of the via hole, the radius of the via hole, and the like.

[0060] The data of the anti-pad includes the radius of the anti-pad and the coordinates of the anti-pad.

[0061] In an implementation manner of this embodiment, the setting module sets the data of the anti-pad according to the data of the via hole may refer to:

[0062] The setting module sets the coordinates of the anti-pad as the coordinates of the via; according to the radius of the via, the size of the aperture of the anti-pad is set, and the radius of the anti-pad is obtained ...

Embodiment 3

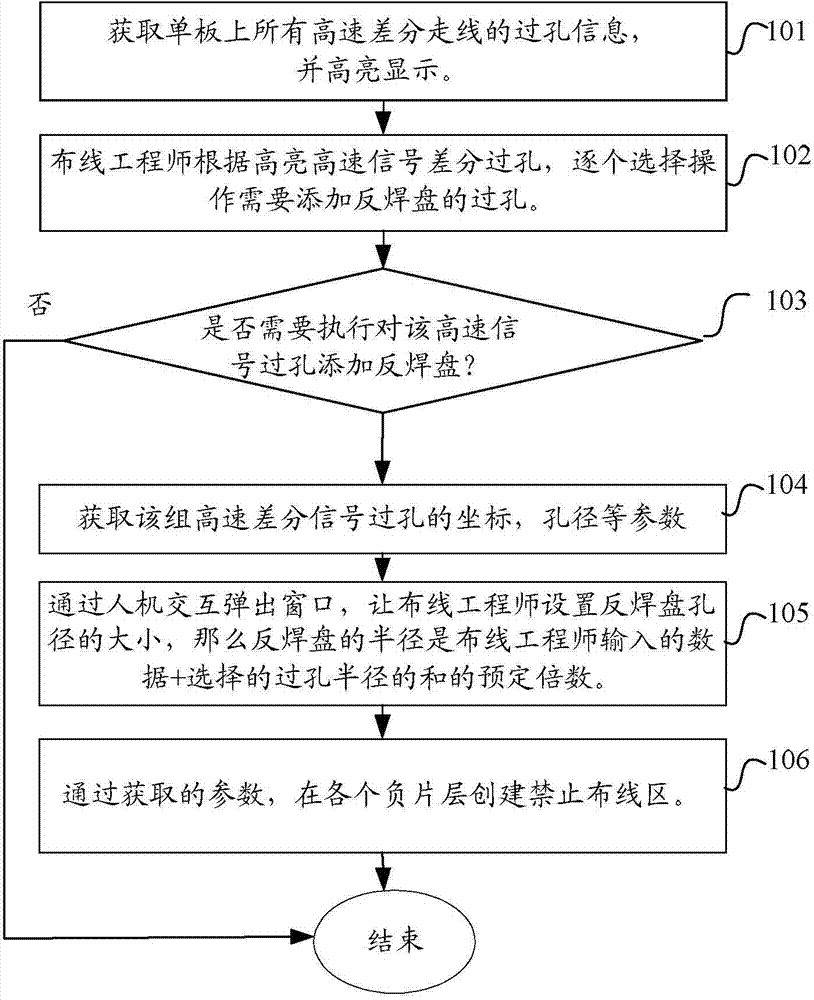

[0066] Embodiment three, such as image 3 As shown in the figure, taking a certain 16-layer CPU computing single board that needs anti-pad setting for a certain high-speed signal as an example, the above method of setting vias on a single board is explained in detail.

[0067]The 16-layer CPU computing board contains 8 negative layers. If you manually make anti-pads for each high-speed signal via, there will be a lot of repeated operations. If you use the above method, it only takes 2 to 3 seconds. , the time advantage is still very obvious.

[0068] Step S301: Obtain the via information of all high-speed signal differential traces on the single board, and display them in a highlighted manner.

[0069] Step S302: The wiring personnel select the vias that need to add anti-pads one by one according to the highlighted vias of the high-speed signal differential routing.

[0070] Step S303: judging whether it is necessary to add an anti-pad to the high-speed signal via hole.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com