Knife switch

A knife switch and deformable surface technology, applied in the direction of electrical components, etc., can solve the problems of poor contact between the moving contact piece and the static contact piece, unstable clamping force, and large amount of wear of the contact piece, so as to avoid deformation and reduce heat generation. , the effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

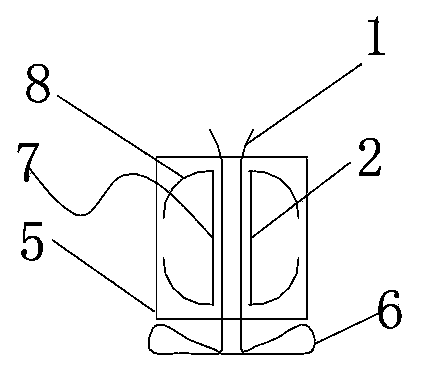

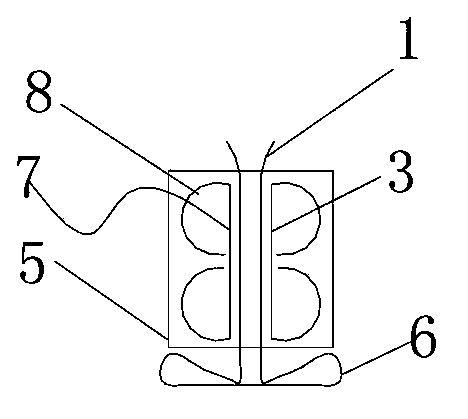

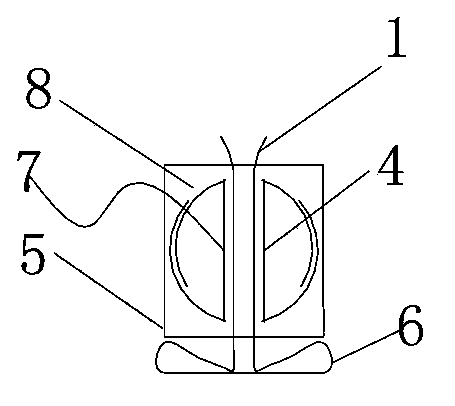

[0030] A knife switch, including an insulating base, a static contact piece 1 fixed on the insulating base, and a moving contact piece whose one end is movably connected to the insulating base, and also includes surface contact springs 2, 3, 4 and a fixing sleeve fixed on the insulating base 5. The surface contact springs 2, 3, 4 include a contact surface 7 in contact with the outer surface of the static contact piece 1, an upper deformation surface 8 connected to the upper end of the contact surface 7, and a lower deformation surface connected to the lower end of the contact surface 7. surface 8, the free end of the upper deformation surface 8 turns back and bends away from the static contact piece 1, and the free end of the lower deformation surface 8 turns back and bends away from the static contact piece 1, and the upper deformation surface 8, the contact surface 7 and The lower deformation surface 8 is an integral structure; the fixed sleeve 5 is provided with a gap for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com