GaN-based light-emitting diode and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as growth layer defects and affect the luminous efficiency of LEDs, and achieve the effect of ensuring crystal quality and improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] As mentioned in the background section, the internal quantum efficiency of blue-green GaN-based LEDs in the prior art still needs to be improved.

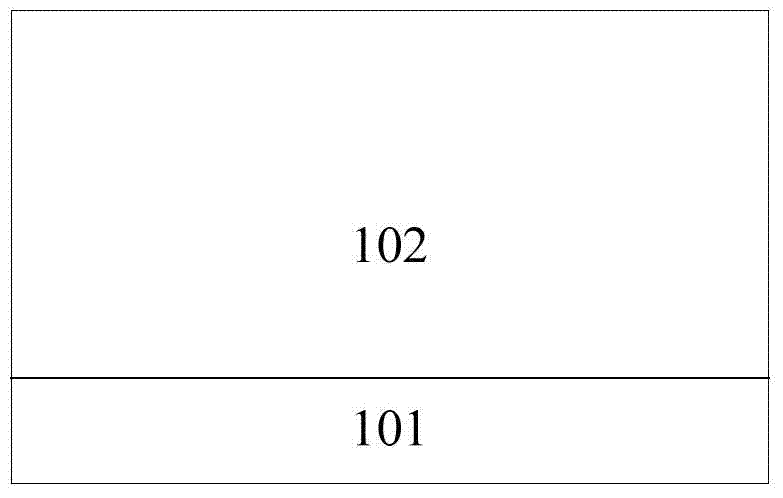

[0073] The inventors have found that the reason for the above phenomenon is that in traditional quantum wells, such as figure 1 As shown, including the well layer 101 and the barrier layer 102 located on the surface of the well layer, during the growth process of the active layer (well layer and barrier layer), along with the In x Ga 1-x N well layer or In y Ga 1-y With the growth of the N barrier layer, the thickness of the active layer increases, the distribution of In components in the well layer or barrier layer becomes uneven, and even at the end of the growth, In "agglomeration" will be formed at the next growth interface. In severe cases, In The nanoscale "ball" (In-droplet), the crystal quality of the next layer structure (well layer or barrier layer) grown under this interface will also deteriorate, which will af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com