A radio frequency power connector

A technology of radio frequency power supply and access device, which is applied to circuits, connections, contact parts, etc., can solve the problems of abnormal radio frequency circuit matching, damage to the radio frequency power generator, and poor heat dissipation performance of cables, so as to reduce the input impedance and improve the Effective output power and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

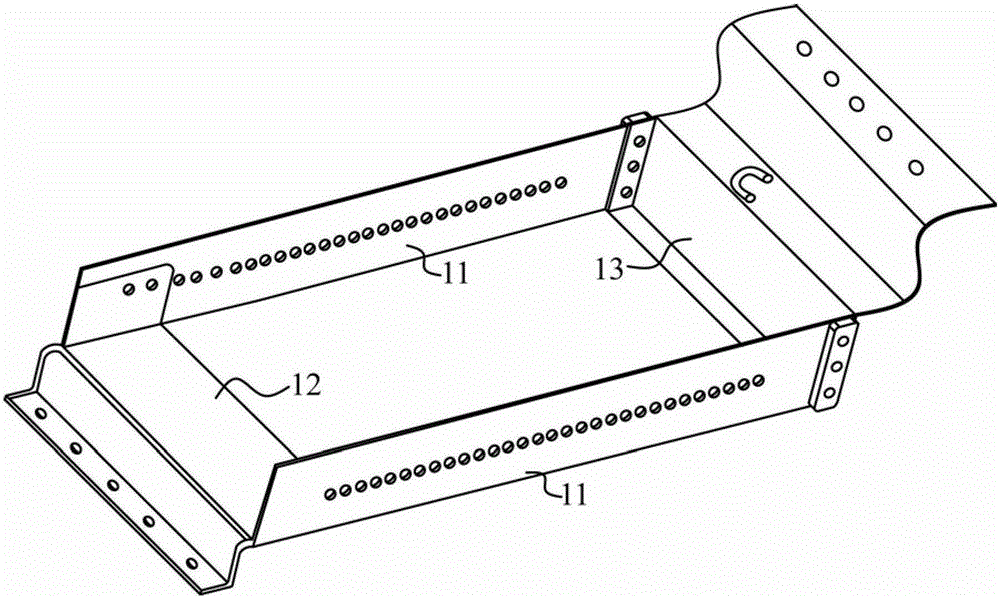

[0024] Such as figure 1 As shown, the first radio frequency access device 1 provided by the embodiment of the present invention specifically includes:

[0025] Two strip-shaped conductive plates 11, the first strip-shaped junction plate 12 for electrically connecting the RF power input end of the chemical vapor deposition PECVD equipment; and the second strip-shaped sink for electrically connecting the RF power output end of the RF power generator connecting plate 13; wherein:

[0026] Two strip-shaped conductive plates 11 are arranged opposite to each other, the two ends of the first strip-shaped connecting plate 12 are respectively connected to one end of a strip-shaped conductive plate 11, and the two ends of the second strip-shaped connecting plate 13 are electrically connected to a strip-shaped conductive plate 13 respectively. the other end of the board.

[0027] figure 1 Shown is a preferred example, the two strip-shaped conductive plates 11 are long strip conductors...

Embodiment 2

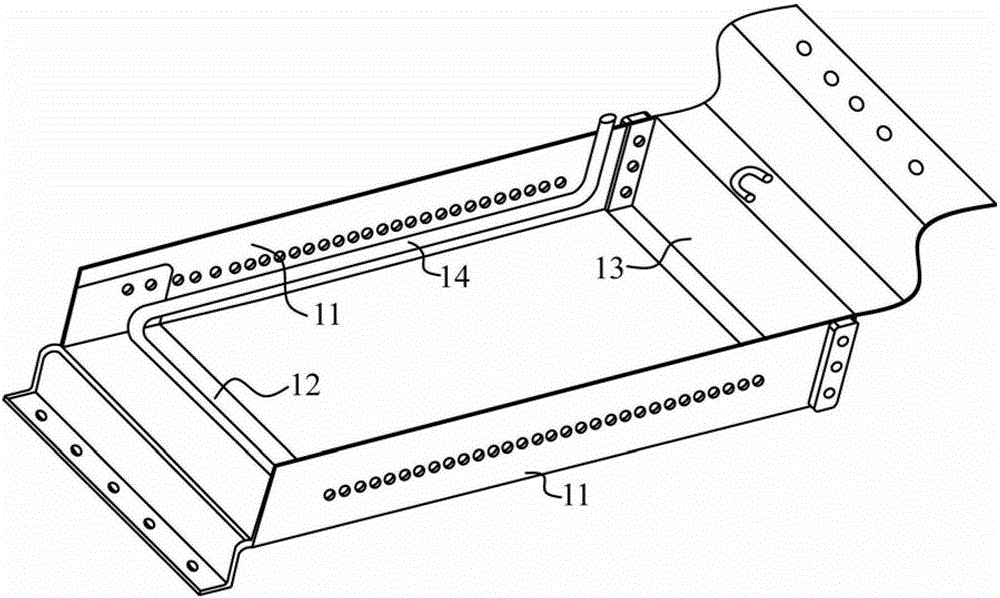

[0031] Such as figure 2 As shown, in order to further improve the heat dissipation capacity, each strip-shaped conductive plate 11 is also welded with a cooling liquid pipe 14 along the length direction. If the surfaces of the two strip-shaped conductive plates are relatively parallel, preferably, the cooling liquid pipe is welded on Each strip-shaped conductive plate 11 is located on a relatively parallel surface, that is, inside the frame-type connector. The two coolant pipes 14 can be as figure 2 The one shown is connected, that is, a heat dissipation pipe, and two ends are respectively connected with an adapter, which is used to connect the input pipe and the output pipe of the cooling liquid. The two cooling liquid pipes can also be independent, and an adapter is respectively connected to the two ends of each cooling liquid pipe, which are respectively used to connect the input pipe and the output pipe of the cooling liquid.

[0032] further as figure 1 with figure...

Embodiment 3

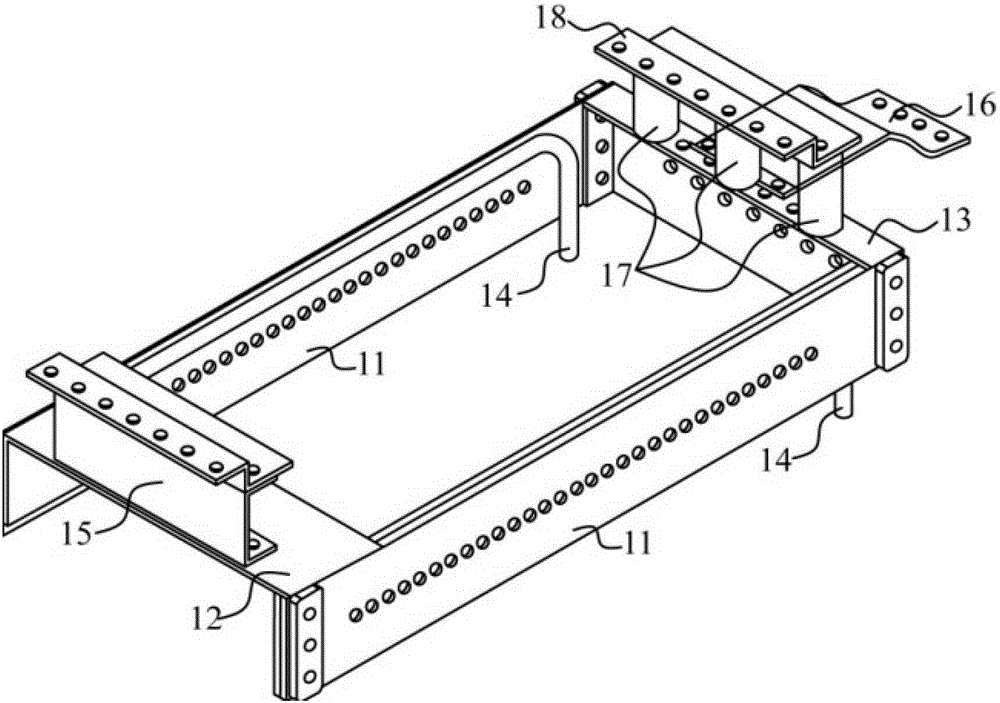

[0034] To further reduce the equivalent impedance, each strip-shaped conductive plate 11 can include a plurality of parallel conductive sub-plates, for example image 3 The two strip-shaped conductive sub-plates are shown in parallel and have a certain distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com