breathing motor

A motor and air guide technology, applied in the field of motors, can solve the problems that the cooling performance of motors is heavily dependent on the direction of rotation of the rotor, the motor has a small load capacity, high development, production and storage costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

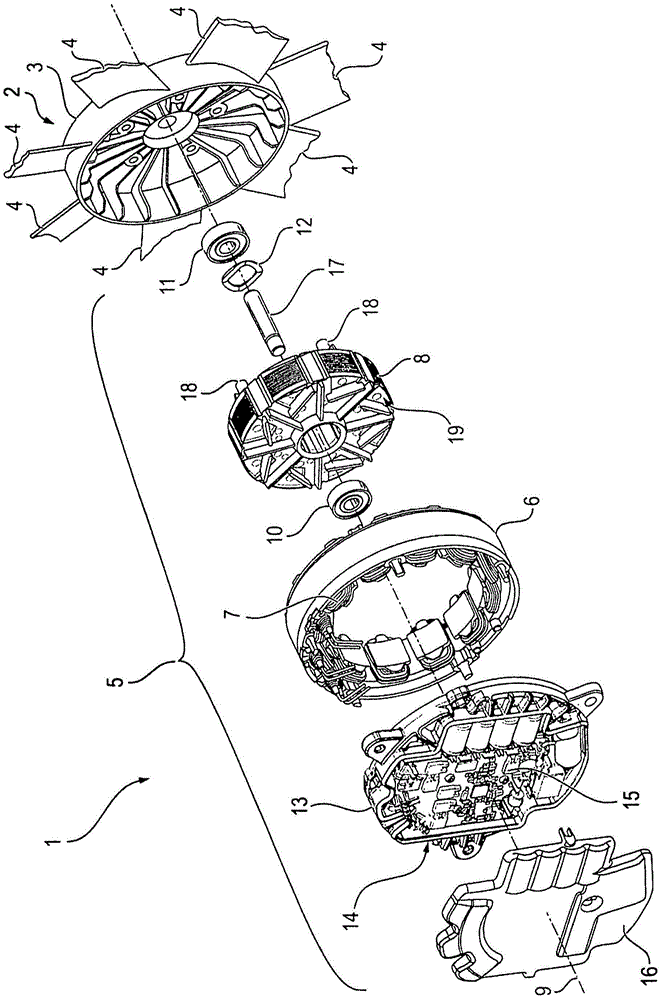

[0033] figure 1Fans 1 for a radiator of a motor vehicle are shown separated from one another. The fan 1 comprises a fan wheel 2 with a shroud 3 around the outer periphery of which seven (only the beginning is shown) air guide vanes 4 are evenly arranged. Furthermore, the fan 1 should comprise a (fan) motor 5 by means of which the fan impeller 2 is driven in rotation.

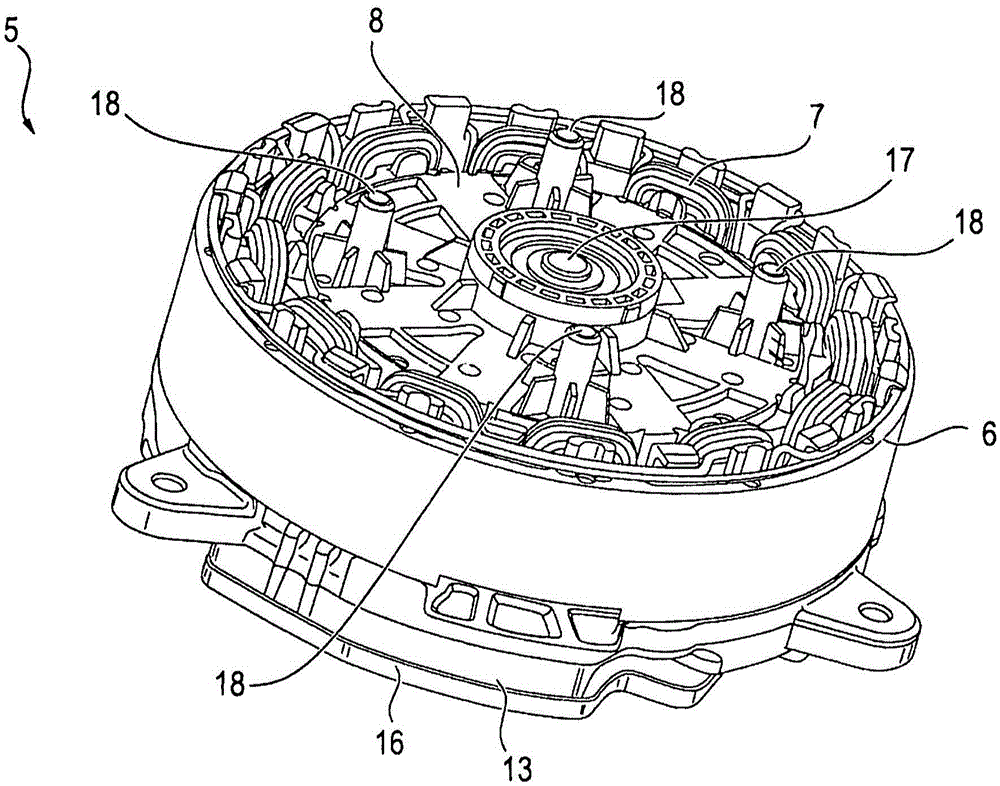

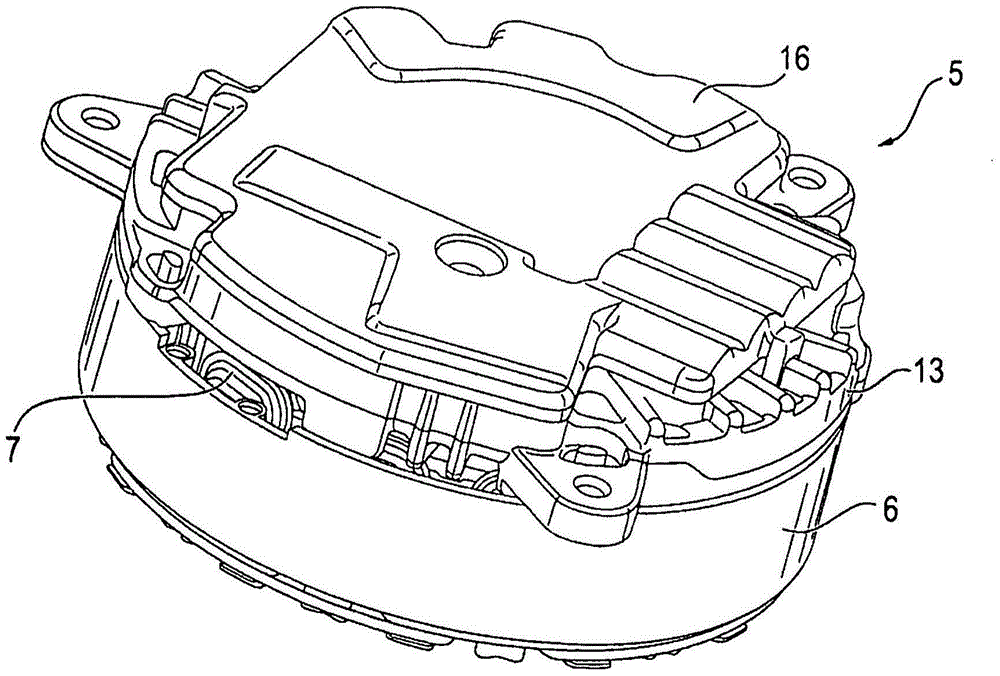

[0034] The electric machine 5 comprises a (hollow-cylindrical for simplicity) stator 6 , which is wound by a three-phase rotating field winding 7 . Furthermore, the electric machine 5 includes a (disc-shaped for simplicity) permanently excited rotor 8 , which is mounted rotatably about a machine axis 9 inside the stator 6 . To support the rotor 8 , the electric machine 5 includes two roller bearings 10 and 11 , which act on the rotor 8 from axially opposite sides. Here, the axial play of the rotor 8 between the two rolling bearings 10 and 11 is spring-loaded by means of spring coils 12 .

[0035] Furthermore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com