Cathode wire for wet electrostatic dust collector

A wet electrostatic and cathodic wire technology, applied in the field of cathodic wires, can solve the problems of corona dead zone, unsatisfactory dust removal and demisting effect, low current density, etc., and achieves low corona initiation voltage, simple structure and good electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

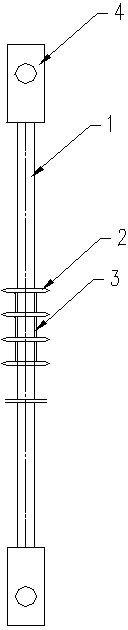

[0015] Such as figure 1 Shown: a cathode wire for a wet electrostatic precipitator, including a cathode rod 1, the cathode rod 1 is a rigid tube or rigid rod to ensure the rigidity and strength of the cathode wire, and a prickly ring 2 is provided on the cathode rod 1 , the discharge tip of the prickly ring 2 has a pointed annular or polygonal structure, so that each direction of the prickly ring 2 has a discharge function, and the cathode rod 1 and the prickly ring 2 are combined into a whole. There is a certain distance 3 between them; connecting pieces 4 are respectively provided at both ends of the cathode rod 1 so that the cathode wires are fixed on the cathode frame through the connecting pieces 4, and the cathode rod 1, the burr ring 2 and the connecting piece 4 are all made of resistant Made of corroded metal material.

[0016] The barbed ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com