Error-control-based smooth interpolation method for five-axis NC (numerical control) system

An error control and interpolation technology, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of processing influence, tool axis attitude error, track error, etc., and achieve the goal of improving stability and processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

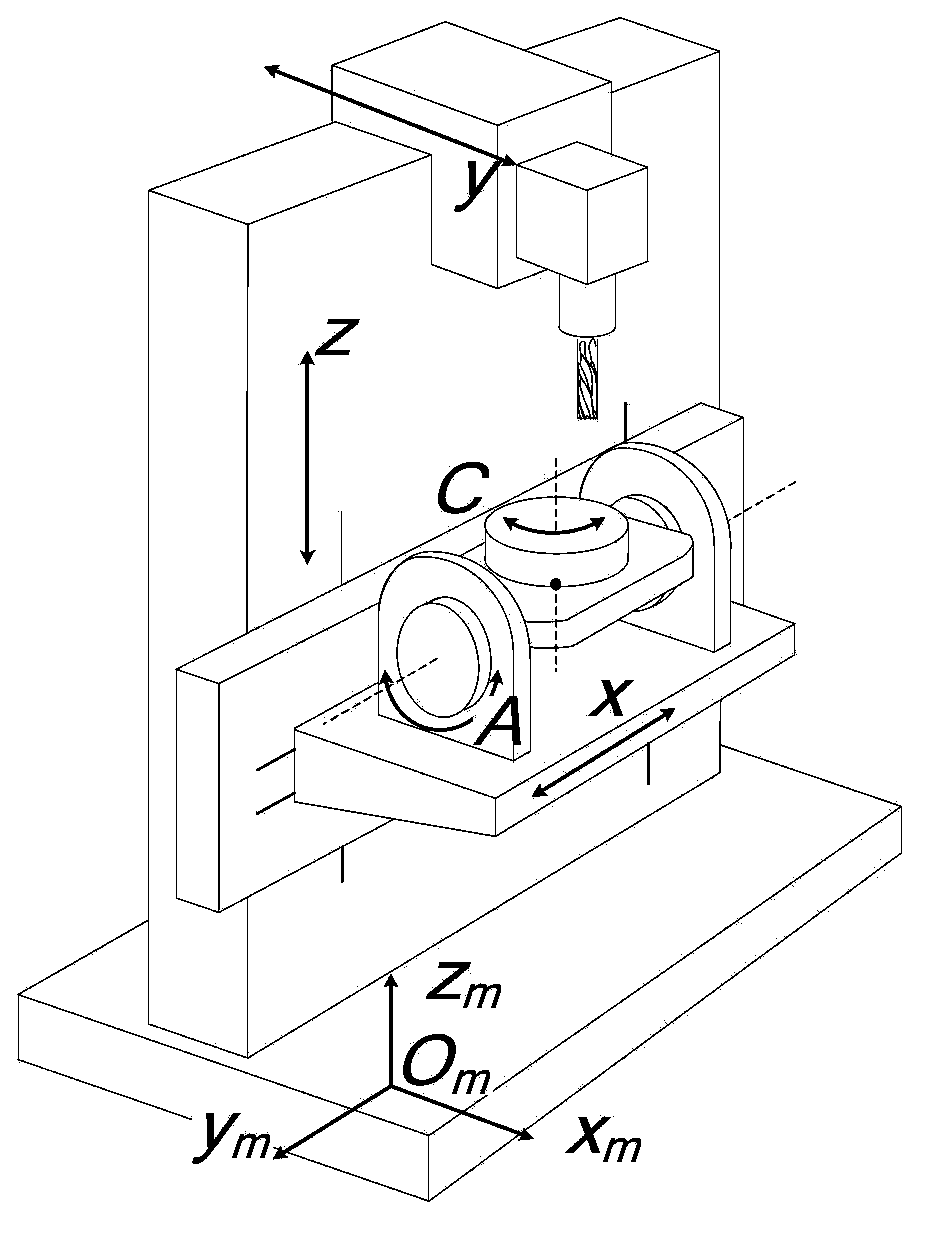

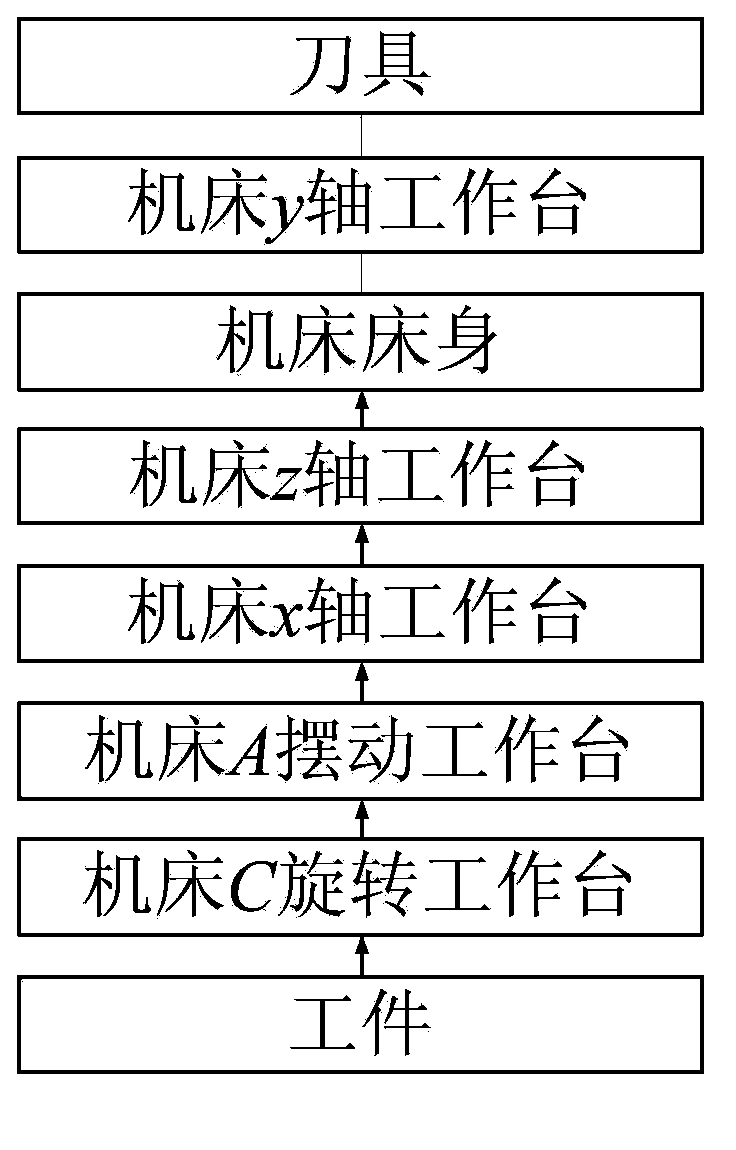

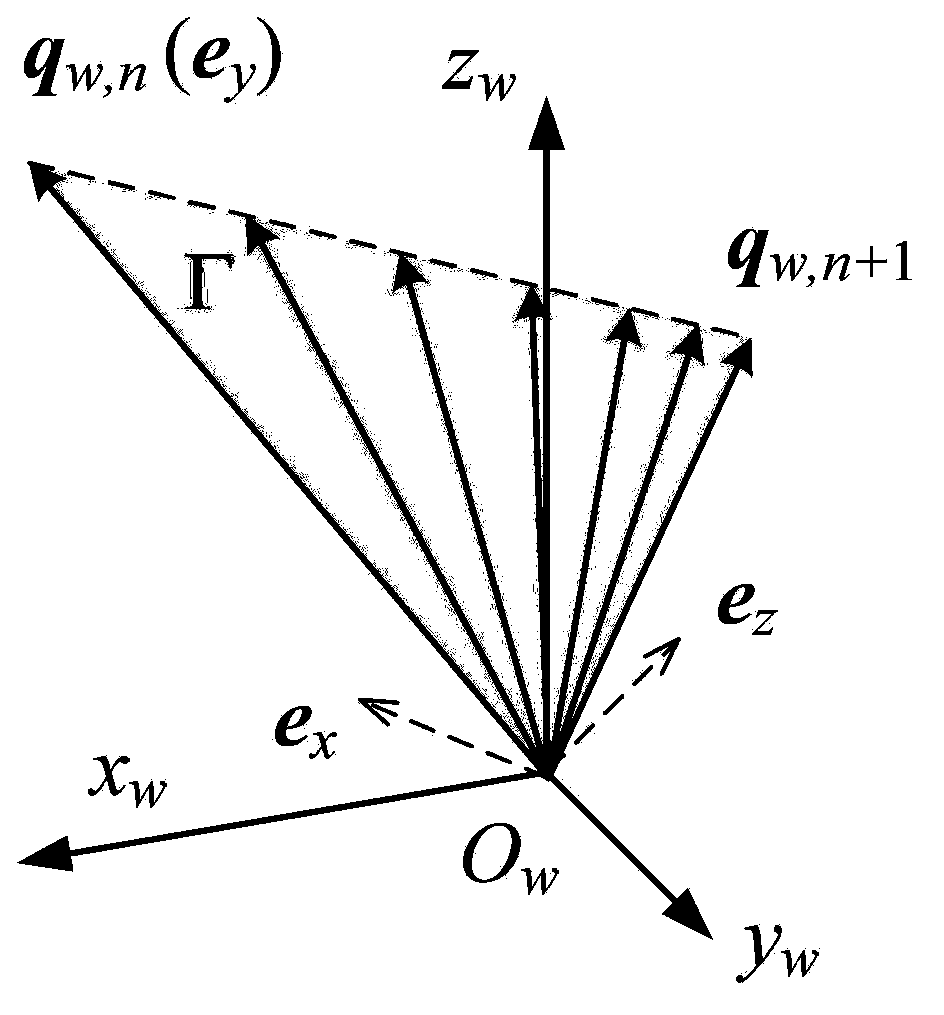

[0029] In this embodiment, the AC double turntable five-axis machine tool is the research object, such as figure 1 Shown is a structural schematic diagram of the AC double turntable five-axis machine tool used in the method of the present invention. figure 2 Kinematic chain for this type of machine tool. The interpolation method based on error control includes the following steps: establishing the forward and reverse kinematics equations of machine tool kinematics; Carry out tilt processing; calculate the nonlinear error at the midpoint, if it exceeds the allowable error, use the interpolation method based on the ideal tool position trajectory for the linear axis.

[0030] For the processing interval composed of adjacent tool position data, the interpolation process is as follows Figure 4 shown.

[0031] Step 1) Establish the forward and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com