Method and device to adjust a predetermined radial tip clearance of a turbomachine blade

一种转子叶片、流体机械的技术,应用在机械设备、叶片的支承元件、金属加工设备等方向,能够解决加工精度损失、低加工精度、流体机械功率影响等问题,达到避免改装时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

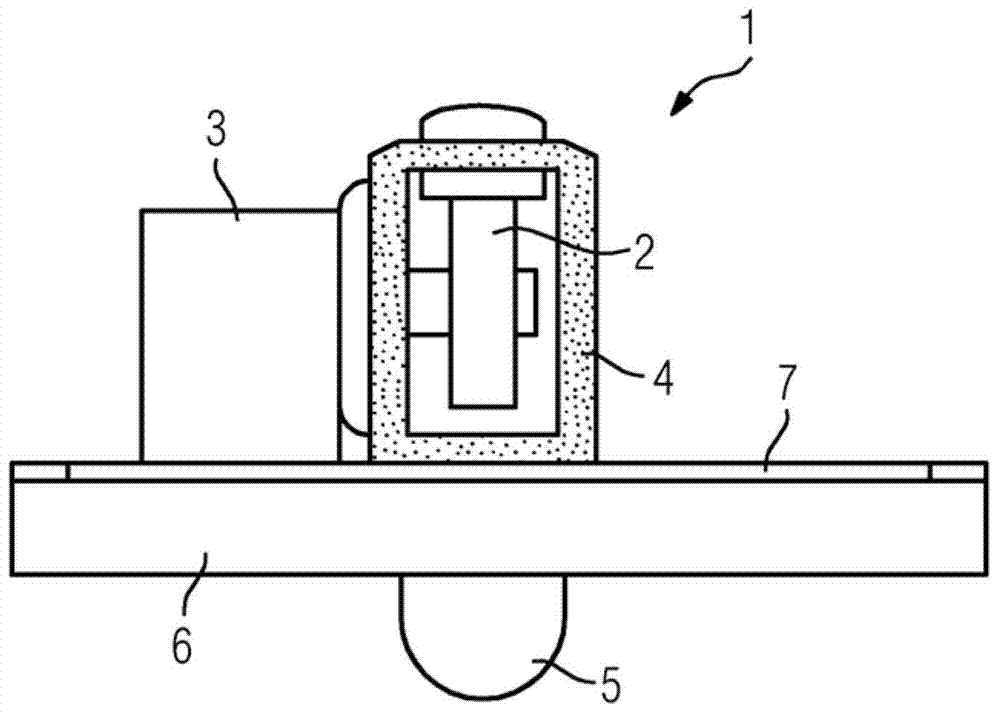

[0025] figure 1 A grinding device 1 according to one embodiment of the invention is shown. The grinding device 1 comprises a grinding disc 2 which is driven in rotation via a drive 3 . The grinding disk 2 is surrounded annularly by a shielding device, which is here formed by a brush device 4 . The brush device 4 comprises a plurality of flexible bristles which protrude beyond the grinding disc 2 so that during normal operation of the grinding device 1 they come into contact with the workpiece to be machined. Furthermore, the grinding device 1 comprises a suction device 5 arranged below the grinding disc 2 , which removes the grinding particles from the shaded processing area of the grinding device 1 during normal operation of the grinding device 1 . The masked processing area is limited by the brush device 4 . The drive of the grinding disc 2 and the suction device 5 are coupled to each other such that the drive is automatically disconnected in the event of a failure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com