Automotive sewage treatment equipment

A technology for sewage treatment equipment and vehicles, applied in the directions of containers, packaging, transportation and packaging, can solve the problems of troublesome operation, difficult to popularize, low degree of automation, etc., and achieve the effect of preventing sewage leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

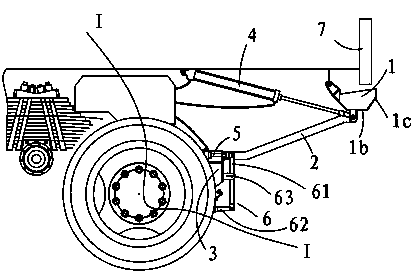

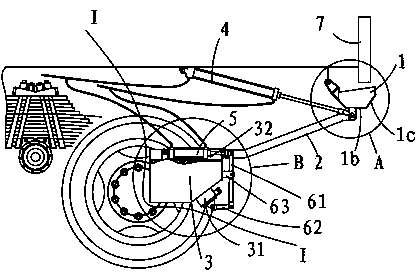

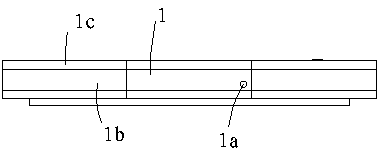

[0031] A vehicle sewage treatment device of the present invention comprises a sump 1 arranged below the car baffle 7, wherein: at least one sewage collection hole 1a is arranged at the bottom of the sump 1, and each sewage collection hole 1a passes through the water collection pipe 2 It is connected with the sewage tank 3 provided on the vehicle body, and the bottom of the sewage tank 3 is provided with a water outlet valve 31, and the sump 1 is rotatably connected and matched with the vehicle body.

[0032] In the embodiment, the water collecting tank 1 is connected with the water collecting tank pulling device 4, one end of the water collecting tank pulling device 4 is fixedly connected with the carriage, and the other end is matched with the water collecting tank 1, when the carriage is in the dumped state, the water collecting tank 1 Under the traction of water tank traction device 4, rotate to the left side position below the carriage baffle plate 7.

[0033] In the embod...

no. 2 example

[0043] The sump pulling device 4 is a hydraulic cylinder, and the water outlet push-pull device 5 is a hydraulic cylinder. The parts not described are the same as the first embodiment.

[0044] In this embodiment, a hydraulic cylinder is used instead of the air cylinder in the first embodiment, so that the sump pulling device 4 and the water outlet pushing and pulling device 5 have better push-pull force and precision.

[0045] The invention can effectively collect the sewage dripped from the loading vehicle, collect the sewage dripped during transportation into the sewage tank, and then dump it when it is suitable to discharge the sewage, so as to prevent the sewage from polluting the road surface. The displacement control of the water outlet valve has a high degree of automation and is easy to operate, which is very suitable for transportation vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com