Descaling method, descaling equipment and descaling system

A kind of equipment and scaling technology, applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of not being able to completely remove scale, affecting oil production operations, and inconvenient dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

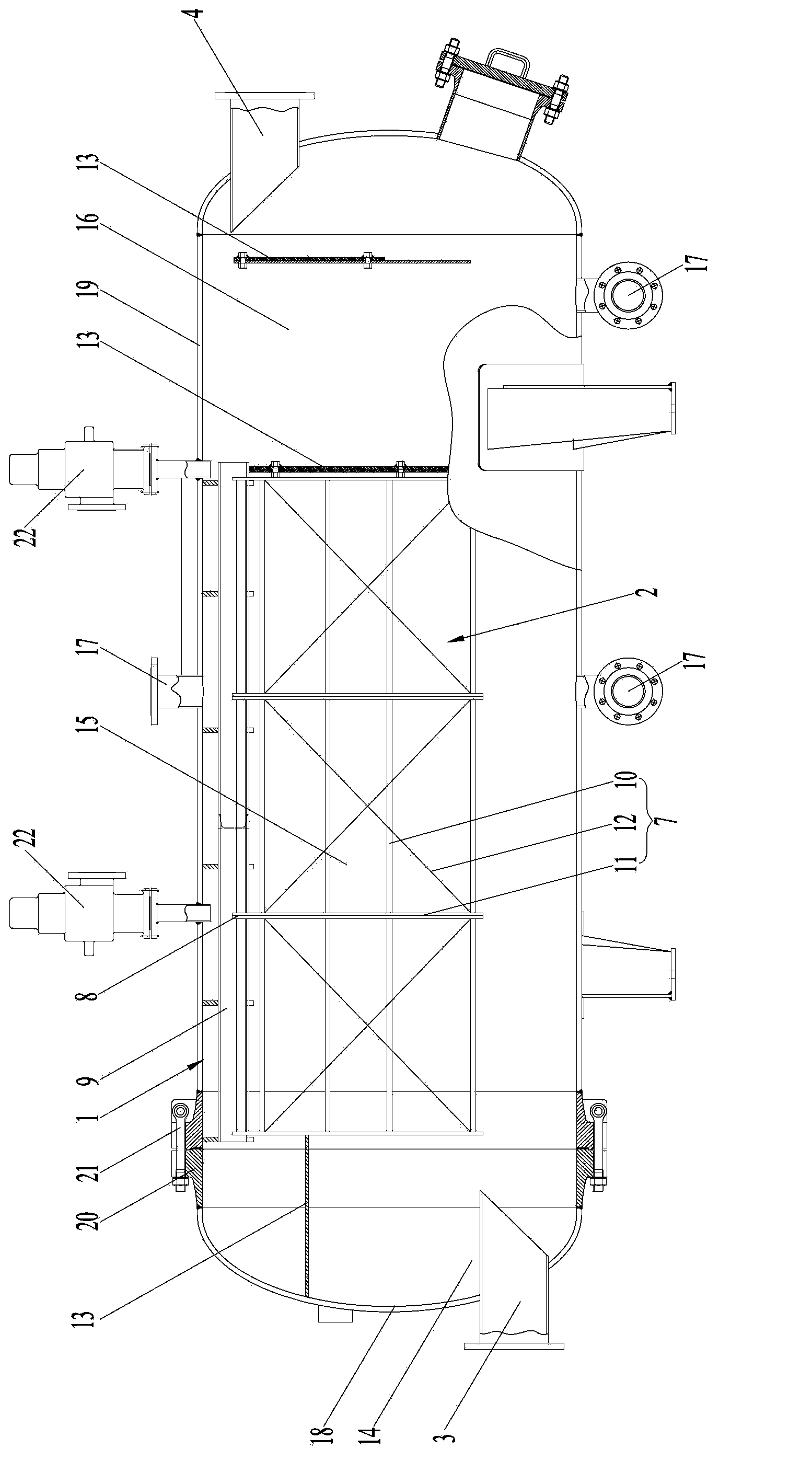

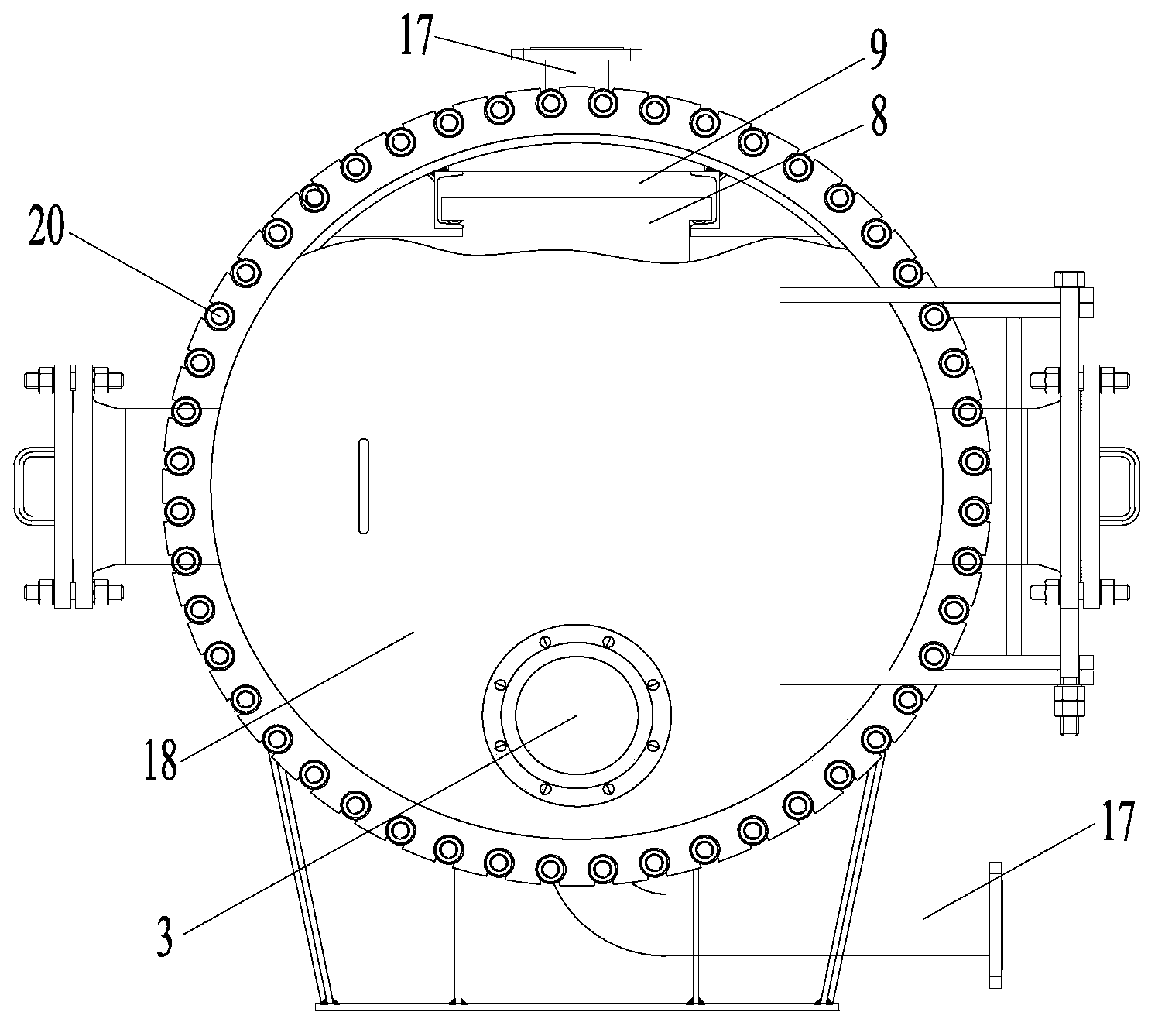

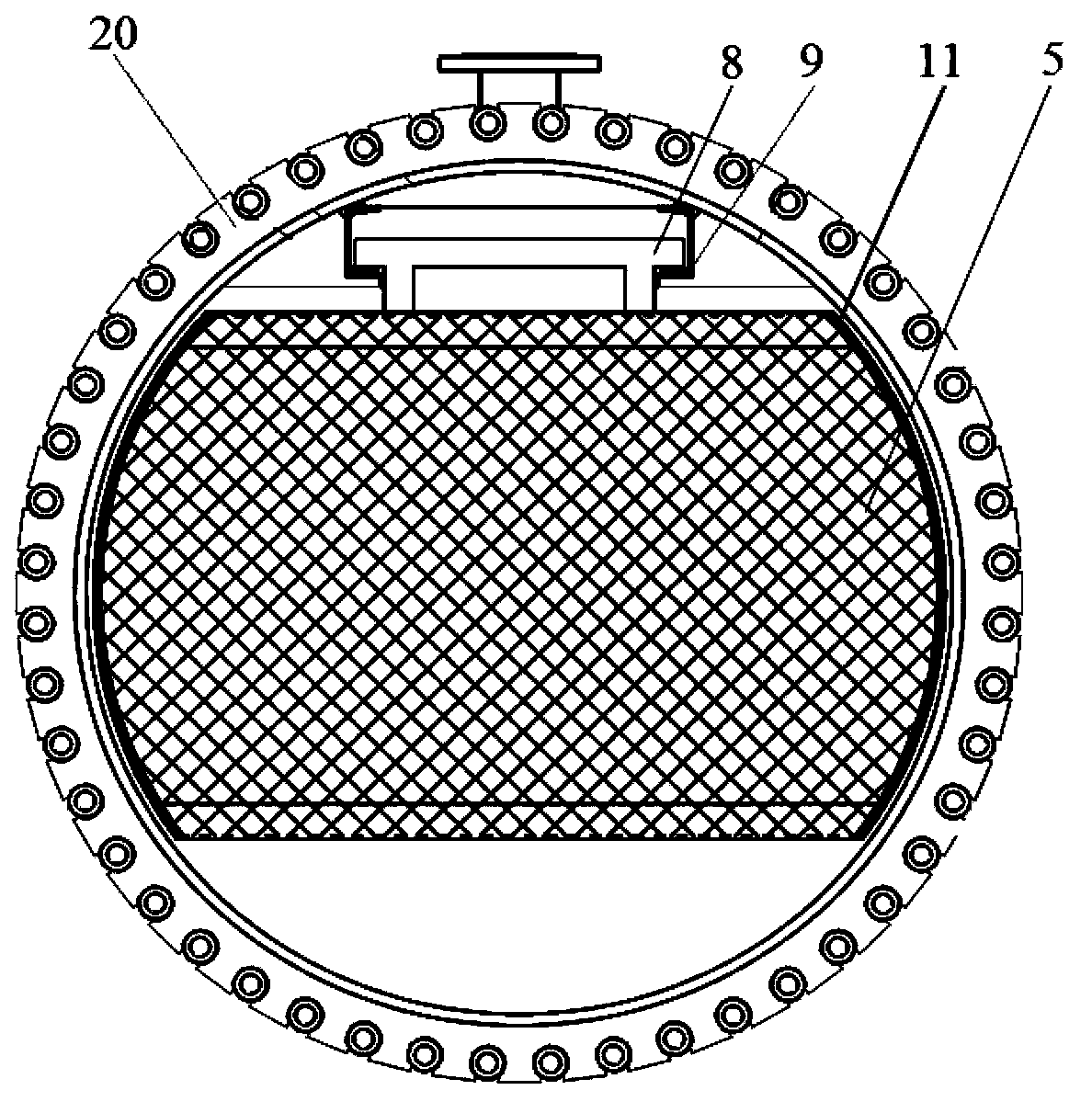

[0052] Such as figure 1 As shown, one aspect of the present invention provides a descaling method, the descaling method comprises making the liquid pass through a contact area of 10m at a flow rate of 0.001m / s~0.004m / s 2 ~30m 2 Fouling unit 2.

[0053] The descaling method of the present invention is to make the liquid (such as crude oil) containing scaling ions flow through the scaling unit 2, and the liquid is in full contact with the scaling unit 2 and the contact area reaches 10m 2 ~30m 2, when the liquid flows in the fouling unit 2, the flow velocity is 0.001m / s~0.004m / s, thus increasing the contact chance of barium strontium sulfate, calcium magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com