Manual single plunger pump with unloading function

A single-column, plug-pump technology, applied to piston pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as high maintenance or replacement parts costs, low system reliability, and high failure rates , to achieve the effect of high work reliability, reliable performance and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

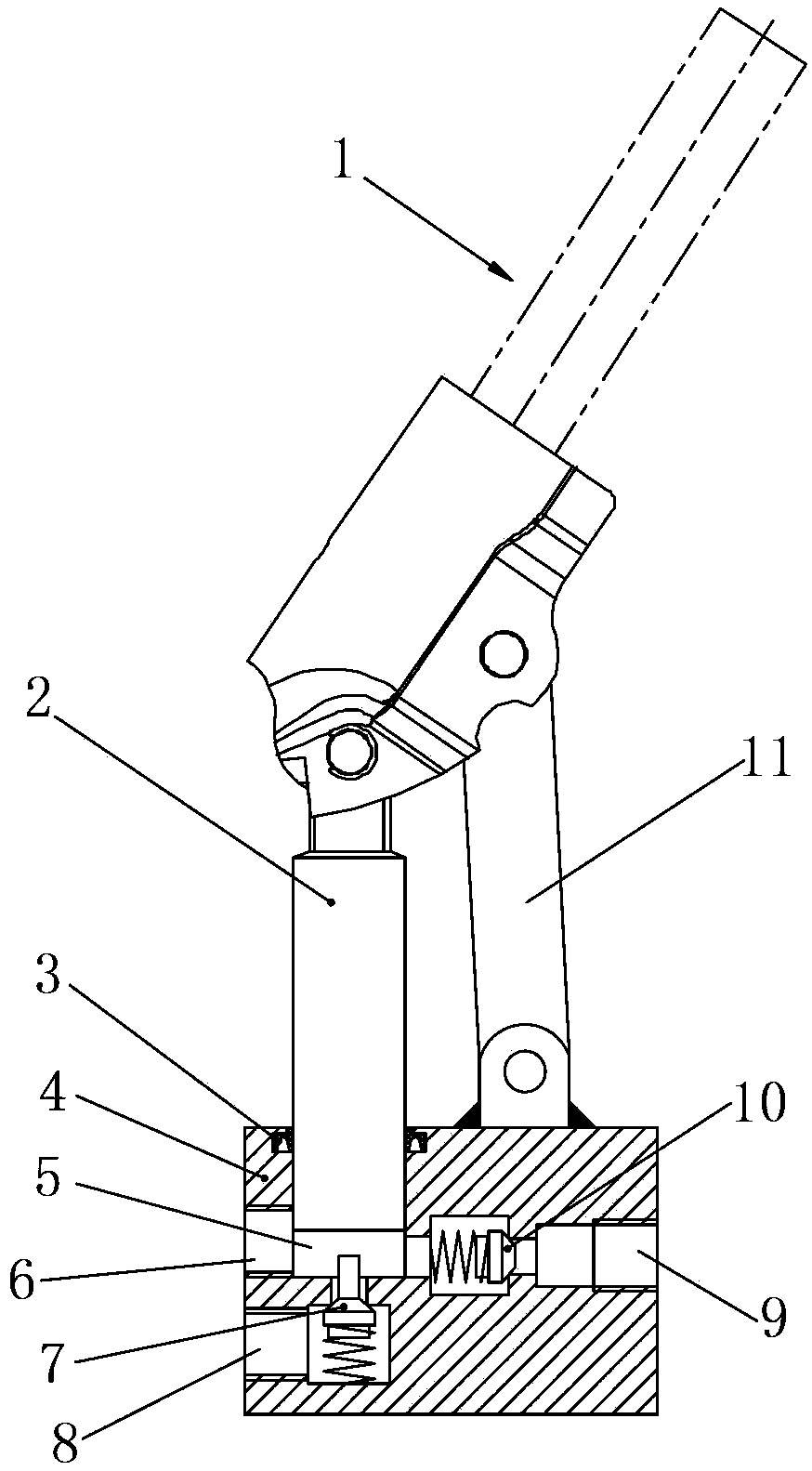

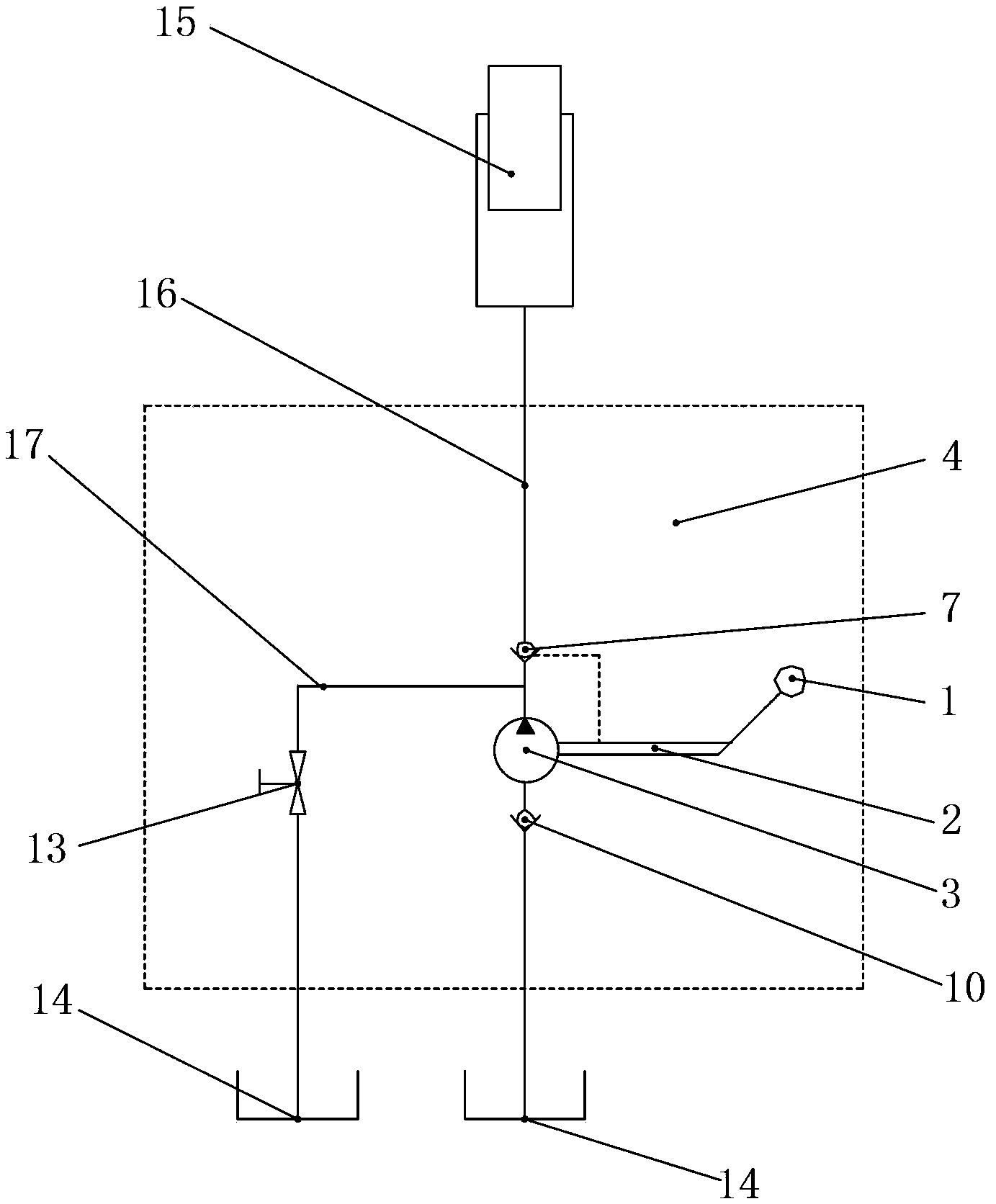

[0021] Such as figure 1 and figure 2 A kind of manual single-plunger pump with unloading function shown, comprises the pump body 4 that is rectangular parallelepiped and hand rocker 1, and described pump body 4 is provided with support bar 11, and the upper end of described support bar 11 is connected with hand crank The middle part of the rod 1 is hinged, and the pump body 4 is provided with a vertically arranged plunger hole 5, the plunger rod 2 is installed in the plunger hole 5, and the upper end of the plunger rod 2 protrudes from the plunger The hole 2 is hinged with one end of the hand rocker 1. The pump body 4 is provided with an oil suction passage 9 and an oil return passage 6 communicating with the plunger hole 2. The oil suction passage 9 and the oil return passage 6 are arranged horizontally. , the oil suction channel 9 and the oil return channel 6 are connected with the oil tank 14, and the oil delivery channel 8 for delivering oil to the plunger cylinder 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com