Bearing limit system and limit method

A technology for bearings and inner rings of bearings, which is applied in the bearing limit system and the limit field, can solve the problems that the limit of long-axis bearings cannot be applied, affects the performance of mechanical equipment, and affects the strength of the shaft, etc., and achieves effective limit, convenient installation, The effect of low quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

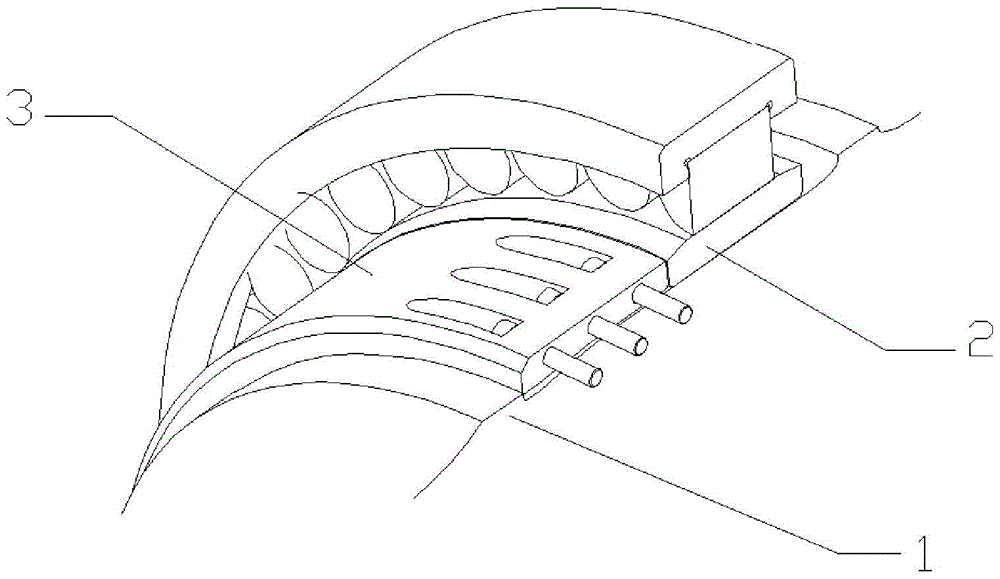

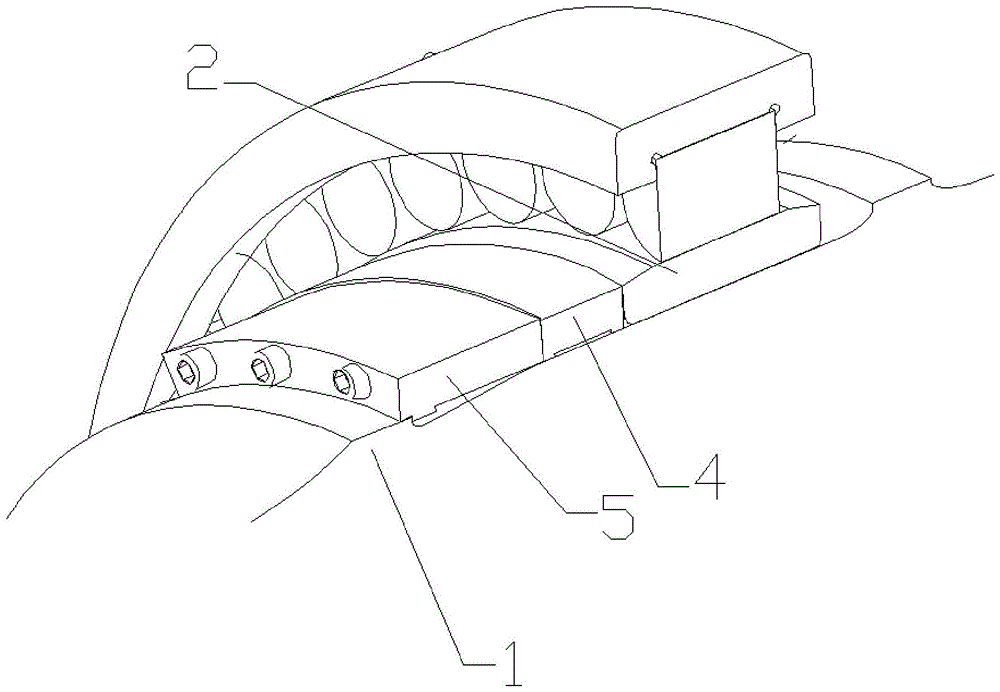

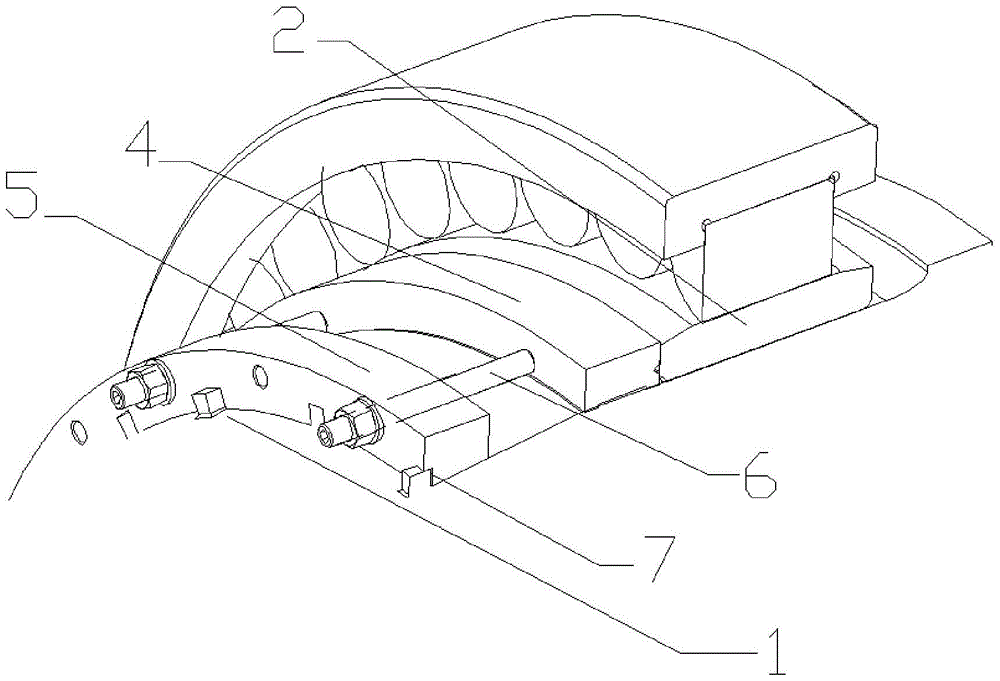

[0031] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0032] refer to figure 1 , figure 2 , image 3 and Figure 4 , The bearing limiting system provided by the specific embodiment of the present invention is applied to a long-axis bearing, the long axis of which is tapered, and the shaft diameter of the section farther from the load end is smaller. In the present invention, the end farther away from the load end and with a smaller shaft diameter is defined as the far end; the end closer to the load end and with a larger shaft diameter is defined as the proximal end. At a certain distance from the bearing installation part, a raised stopper or a raised retaining ring (that is, a limit protrusion 1) is designed, and the outer diameter of the stopper or retaining ring is not larger than the inner diameter of the bearing inner ring 2, so as to ensure that the inner ring of the bearing is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com