Oil separator as well as compressor and refrigerating system using oil separator

An oil separator and refrigeration system technology, applied in the field of compressors, can solve the problems of lack of oil in the compressor and incomplete separation of oil and gas, and achieve the effects of reducing wear, shortening the circulation path, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

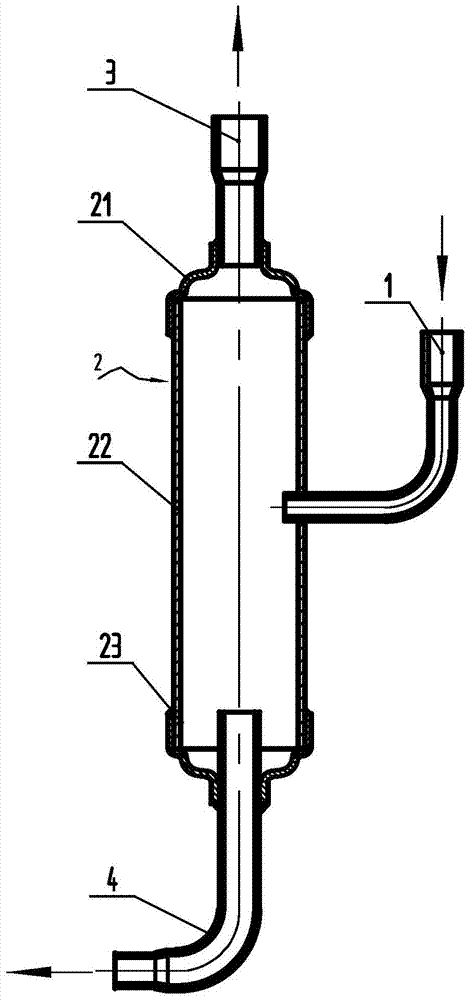

[0039] figure 2 Shown is a first embodiment of the invention, as figure 2 The oil separator 10 shown is used to realize the separation of lubricating oil and refrigerant in the refrigeration system. The refrigeration system includes a compressor and a condenser, and the oil separator is connected between the compressor and the condenser. , the oil separator is a single structure, including cylinder 2, inlet pipe 1, outlet pipe 3 and oil return pipe 4, the inlet pipe 1 is used to connect with the exhaust pipe of the compressor, the outlet The air pipe is used to connect the condenser, and one end of the oil return pipe 4 extends into the barrel 2, and the other end is connected to the compressor oil pool.

[0040] Depend on figure 2 It can be seen that the cylinder 2 is a closed cylinder, the air inlet pipe 1 extends from the middle of the cylinder 2, the air outlet pipe 3 protrudes from the top of the cylinder, and the oil return pipe One end extends into the cylinder bo...

Embodiment 2

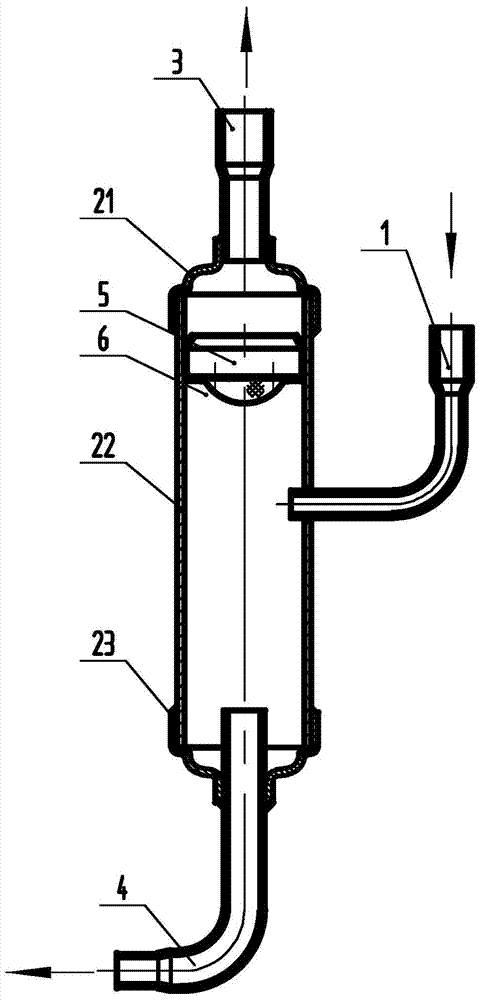

[0045] image 3 Shown is a second embodiment of the invention, as image 3 The oil separator 10 shown is used to realize the separation of lubricating oil and refrigerant in the refrigeration system. The refrigeration system includes a compressor and a condenser, and the oil separator is connected between the compressor and the condenser. , the oil separator is a single structure, including cylinder 2, inlet pipe 1, outlet pipe 3 and oil return pipe 4, the inlet pipe 1 is used to connect with the exhaust pipe of the compressor, the outlet The air pipe is used to connect the condenser, and one end of the oil return pipe 4 extends into the barrel 2, and the other end is connected to the compressor oil pool. The difference from Embodiment 1 is that the oil separator of Embodiment 2 also includes a filter assembly, which is placed inside the cylinder and at the front end of the outlet pipe 3, and the filter assembly includes a filter screen 5 And the filter screen support 6, the...

Embodiment 3

[0048] Figure 4 Shown is the third embodiment of the present invention, the structure of this embodiment is basically the same as the second embodiment, and the difference from the first embodiment is that the filter group of the oil separator of the third embodiment is placed at the front end of the oil return pipe 4, so The filter assembly includes a filter screen 5 and a filter screen support 6, the filter screen support 6 is fixedly connected to the cylinder body 22, the filter screen 5 is covered on the support in an arc shape, and the arc surface of the filter screen is convex upward out. Set the filter screen assembly at the front end of the oil return pipe 4 to prevent impurities from falling into the oil return pipe, and ensure that after the impurities are separated from the oil-air mixture, the returned lubricating oil, especially large particles of impurities, will no longer flow back to the oil pool of the compressor with the refrigerant , which can reduce the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com