Dual-data bus-type master-slave controller with built-in PLC function

A master controller and data bus technology, applied in the field of dual data bus type master-slave controllers, can solve the problems of reducing the use efficiency of the controller, slow response speed, and low system integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

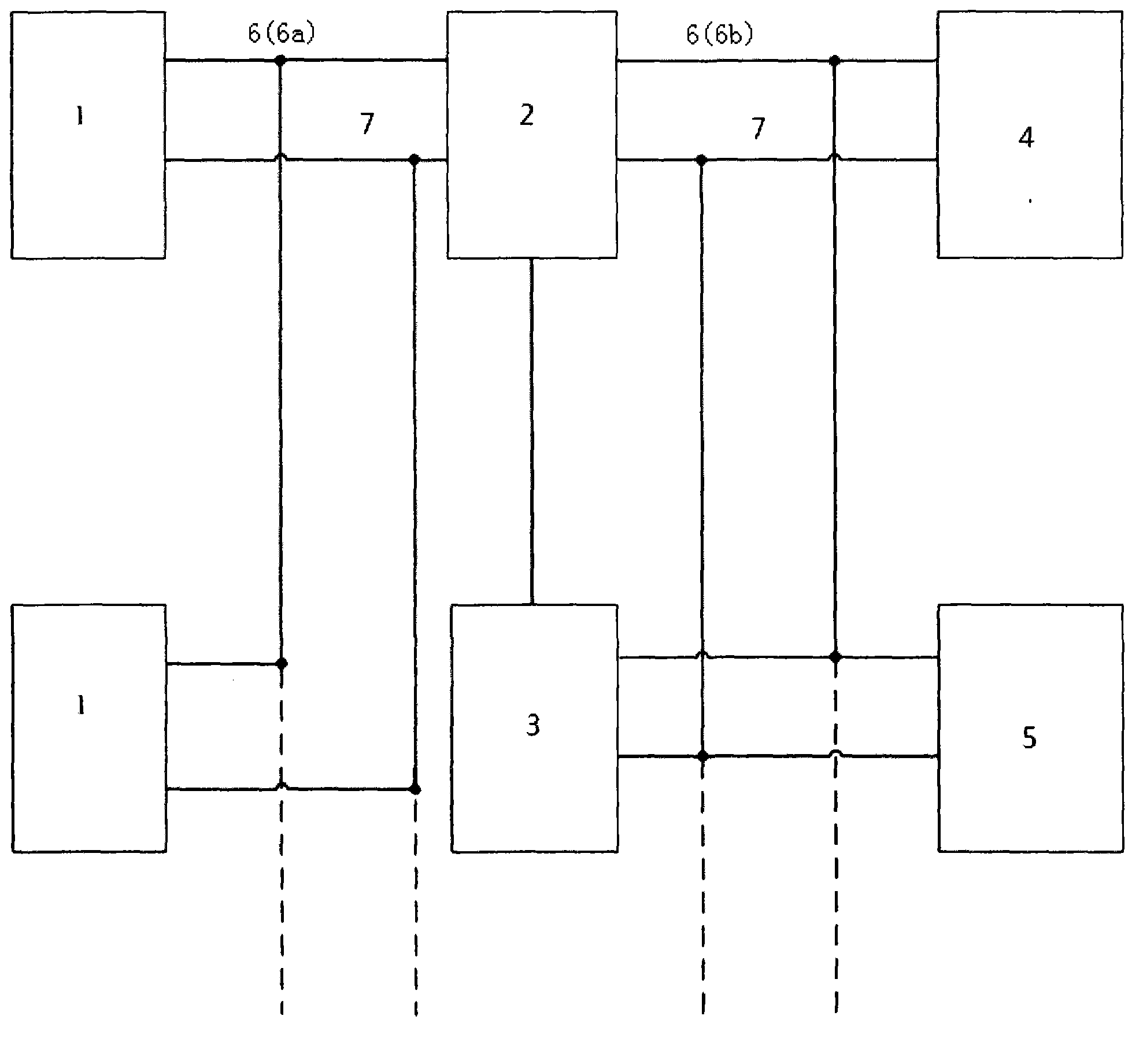

[0027] See figure 1 , the dual data line master-slave controller 9 architecture with built-in PLC function is an open system, the two internal data buses 6 can be expanded as needed, and MCPU unit 2, SCPPU unit 3, AIO unit 4, DIO unit 5 and AEU Unit 1 can also be expanded and selected according to specific application needs.

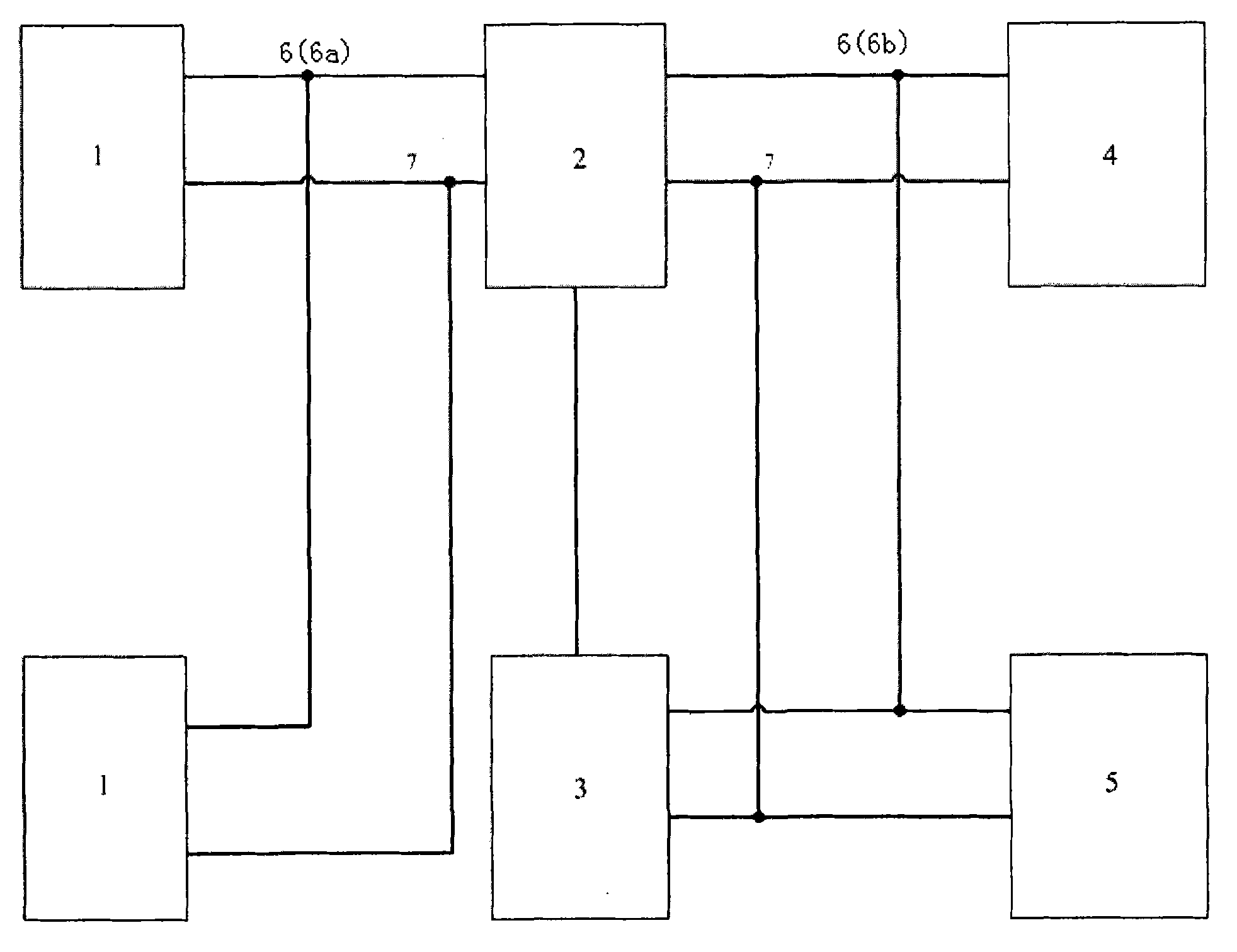

[0028] See figure 2 , a dual data bus master-slave controller with built-in PLC function 9 is used in a schematic diagram of an implementation example of a single set of equipment, which is suitable for multi-level power electronic equipment such as three-level, industrial products using various control methods, It is used in a variety of individual equipment such as industrial equipment for various application processes.

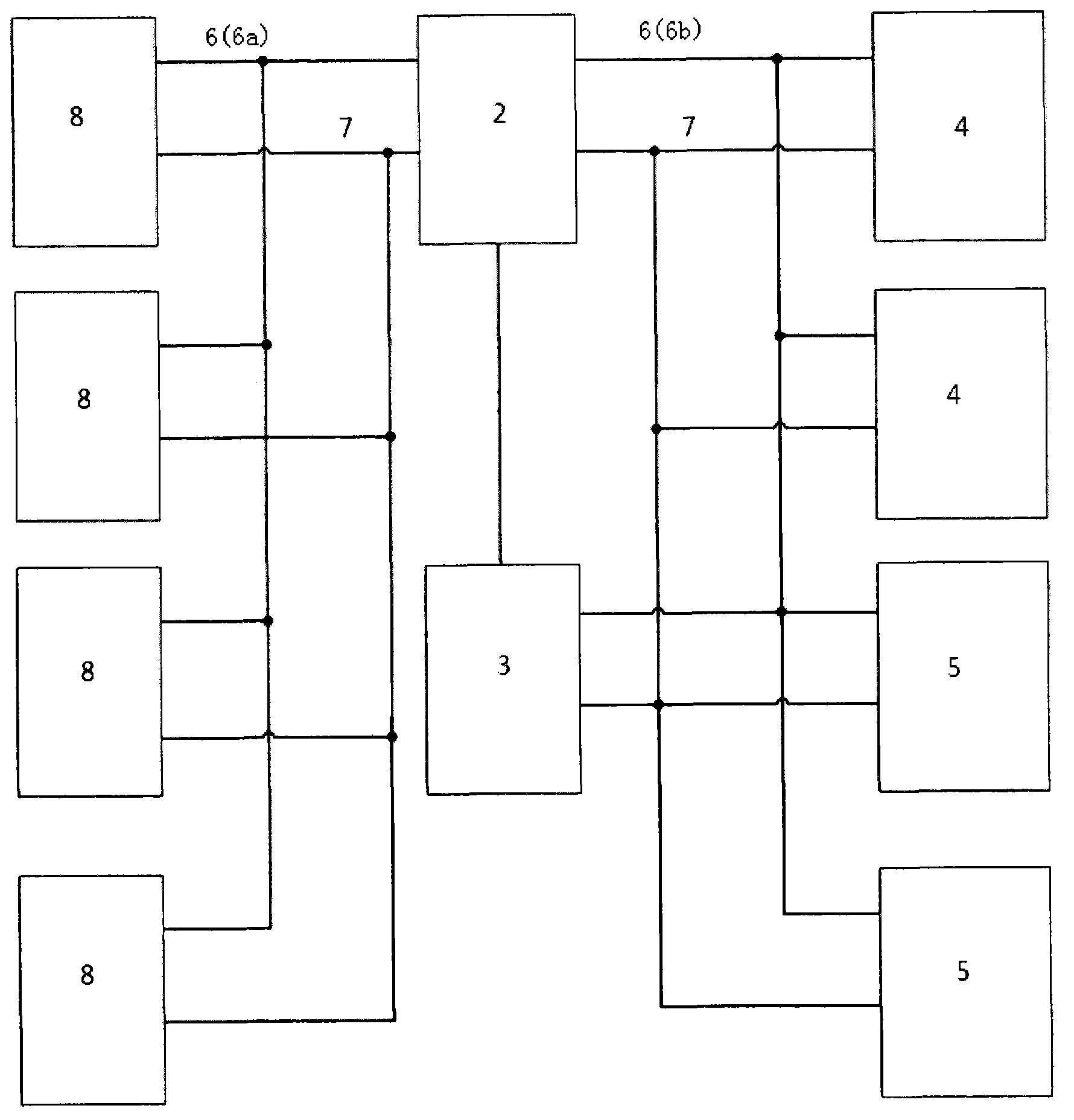

[0029] See image 3 , a schematic diagram of an implementation example of a du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com