Real-time production scheduling management system and method based on mobile terminals

A mobile terminal and production scheduling technology, which is applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of not being able to grasp the production status of the production site in time, batch production on the assembly line, and difficulty in achieving balanced production, etc., to save paper Management mode, improvement of production efficiency, effect of improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

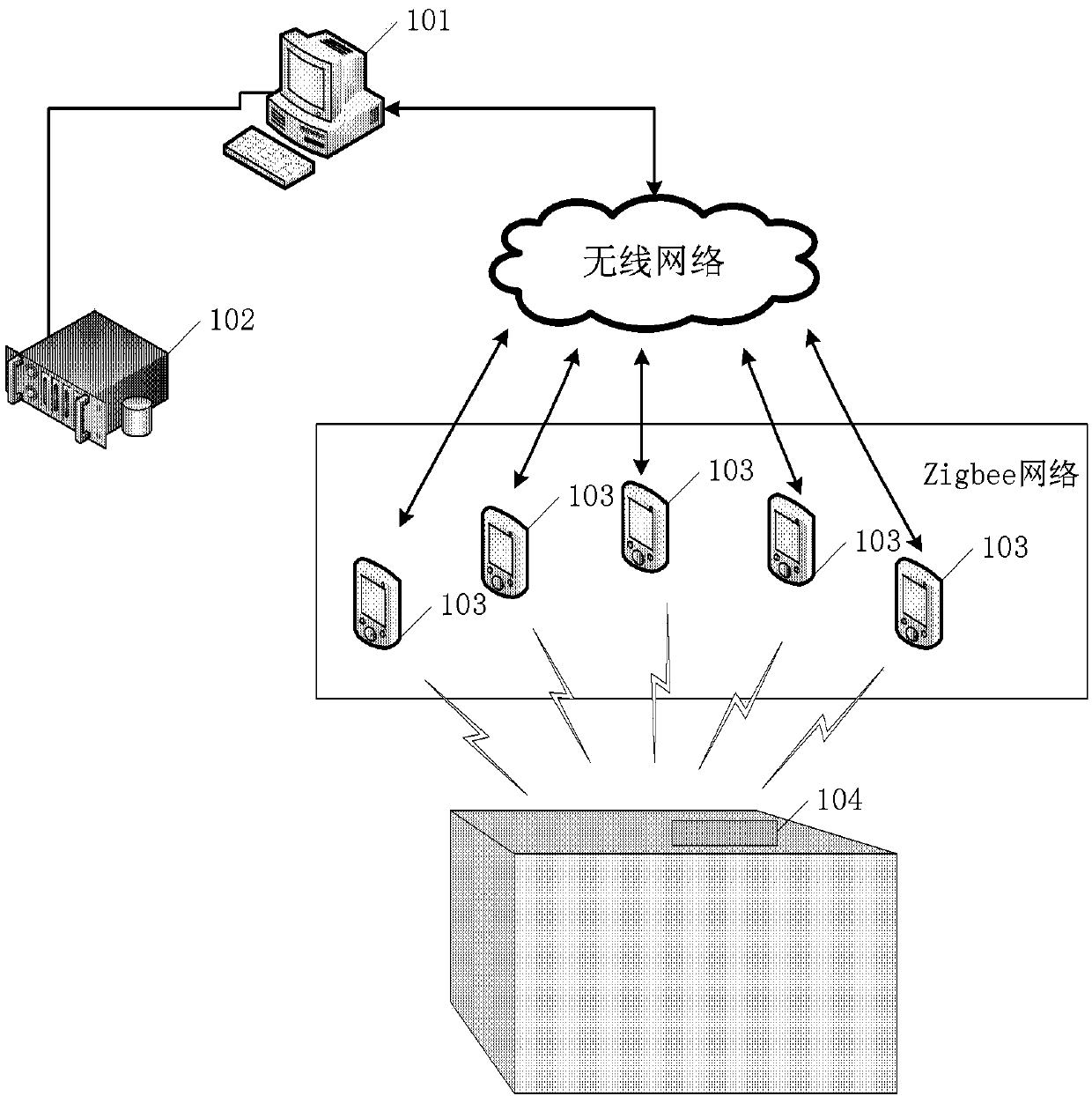

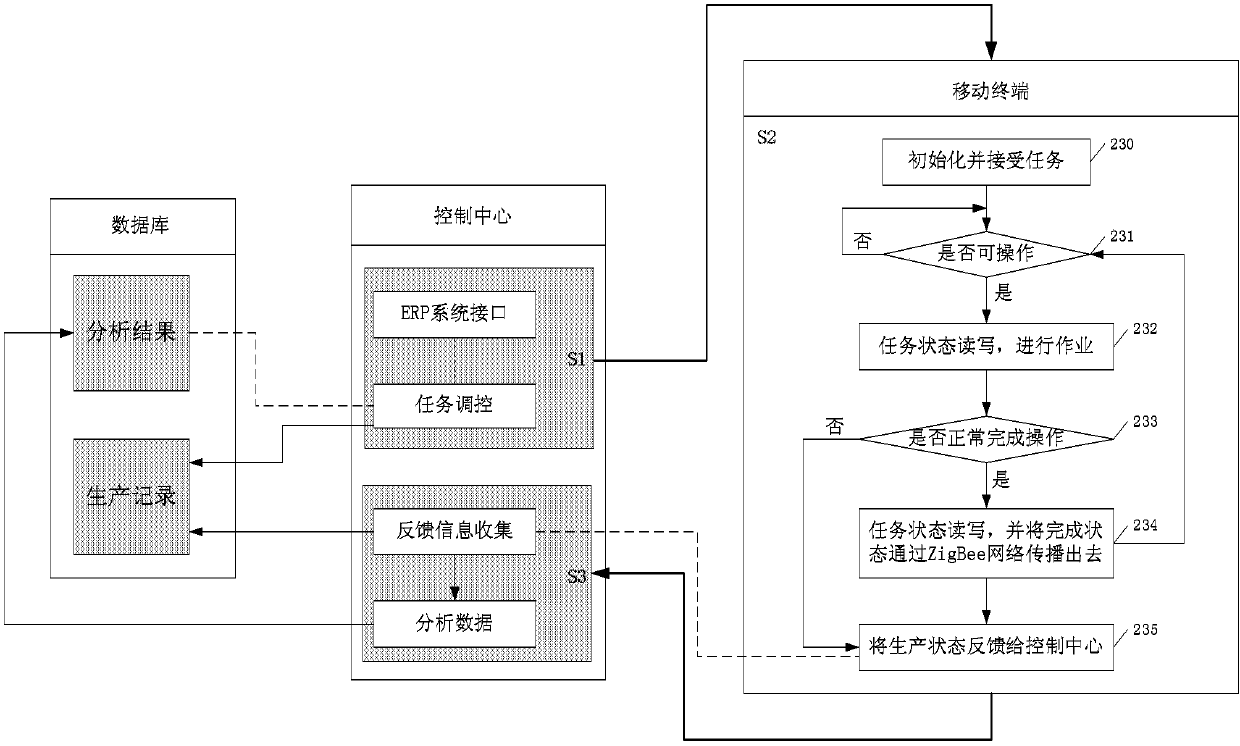

[0024] The mobile terminal-based real-time scheduling management system and method disclosed in the present invention realize the seamless link between the scheduling management department and the workshop management through the mobile terminal, the whole process of automatic management, and unified monitoring and management of the production site; Allocate and notify each worker to realize rapid sharing of production status, determine the order in which products can be assembled, and promptly notify workers in relevant processes to carry out operations to ensure that on-site workers work in an orderly manner, manage on-site workers, and ensure Scheduling management personnel can understand the working status of workers in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com