Novel ceramic capacitor

A technology of ceramic capacitors and ceramics, applied in fixed capacitor electrodes, fixed capacitor leads, fixed capacitor shells/packages, etc., can solve the problems of ceramic capacitors with reduced insulation resistance, inability to mold, low production efficiency, etc., to avoid insulation resistance The effect of falling, good insulation of water vapor, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

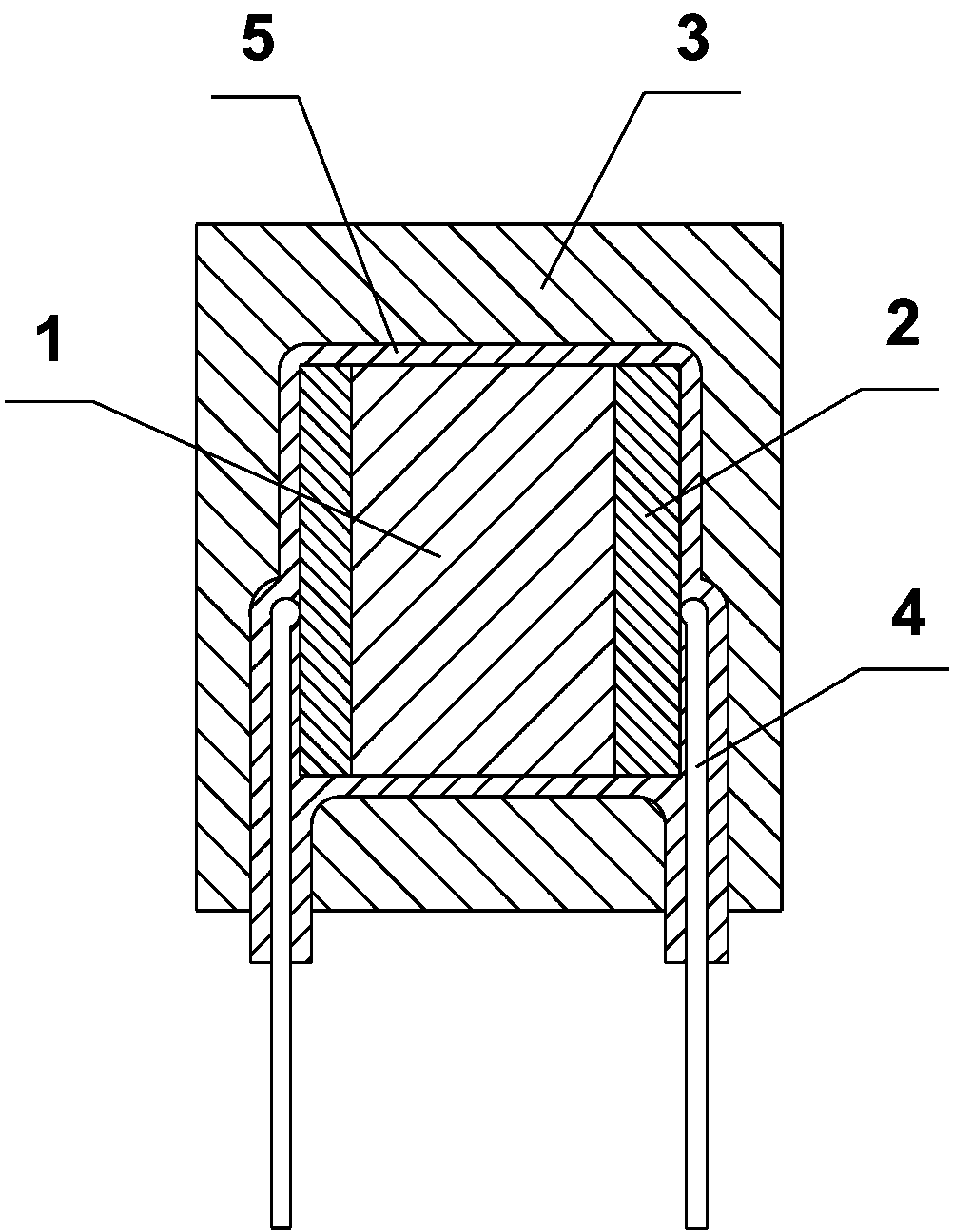

[0009] As an embodiment of the present invention, such as figure 1 As shown, a novel ceramic capacitor includes a ceramic chip 1, the ceramic chip 1 is in the shape of a cuboid, and tin electrodes 2 are respectively fixedly connected to the opposite sides of the ceramic chip 1, and the use of the tin electrode 2 can increase the size of the ceramic capacitor. The dielectric constant makes the ceramic capacitor produce a large capacitance in the case of a small volume, and give full play to the stability and reliability of the capacitor. It is suitable for application in small communication devices such as mobile phones and palmtop computers. The ceramic chip 1 and the tin electrode 2 are provided with an epoxy resin encapsulation layer 3, and the two tin electrodes 2 are respectively provided with a pin 4, and the cross section of the pin 4 is rectangular, so that the pin 4 of the ceramic capacitor can Located at the same height, during production, multiple ceramic capacitors...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com