Xenon lamp

A xenon lamp and cavity technology, which is applied in the field of xenon lamps, can solve the problems of long distance, light exit point, low discharge efficiency, affecting the focusing performance and beam quality of xenon lamps, etc., to increase the breakdown area and beam quality Good, good light-gathering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and embodiments.

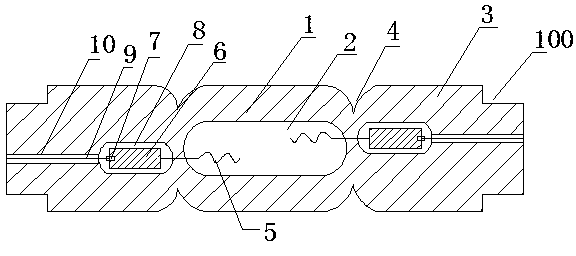

[0015] Such as figure 1 Shown is a schematic diagram of the structure of the xenon lamp of this embodiment,

[0016] In the figure, a xenon lamp includes a discharge vessel 100 composed of a quartz tube. The discharge vessel 100 has a light-emitting portion 1 and side tube portions 3 extending continuously at both ends of the light-emitting portion 1. The light-emitting portion 1 and The side tube portion 3 is separated by the neck 4, and a closed discharge cavity 2 is provided inside the light emitting portion 1. The discharge cavity 2 is filled with inert gas, and two opposite electrodes 5 extend into the discharge cavity 2 , The electrodes 5 extending into the discharge cavity 2 are in a spiral shape and are arranged opposite to the two ends of the tube axis of the discharge cavity 2. The distance between the electrodes 5 and the discharge cavity 2 is 0.3-1mm, It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com