Automatic production line of power flexible packaged lithium battery liquid injection presealing opening

A technology for automated production lines and soft-packed lithium batteries, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of production equipment downtime and long waiting time, scattered production equipment layout, large footprint, etc., to reduce The effect of duplication of labor, high production efficiency, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

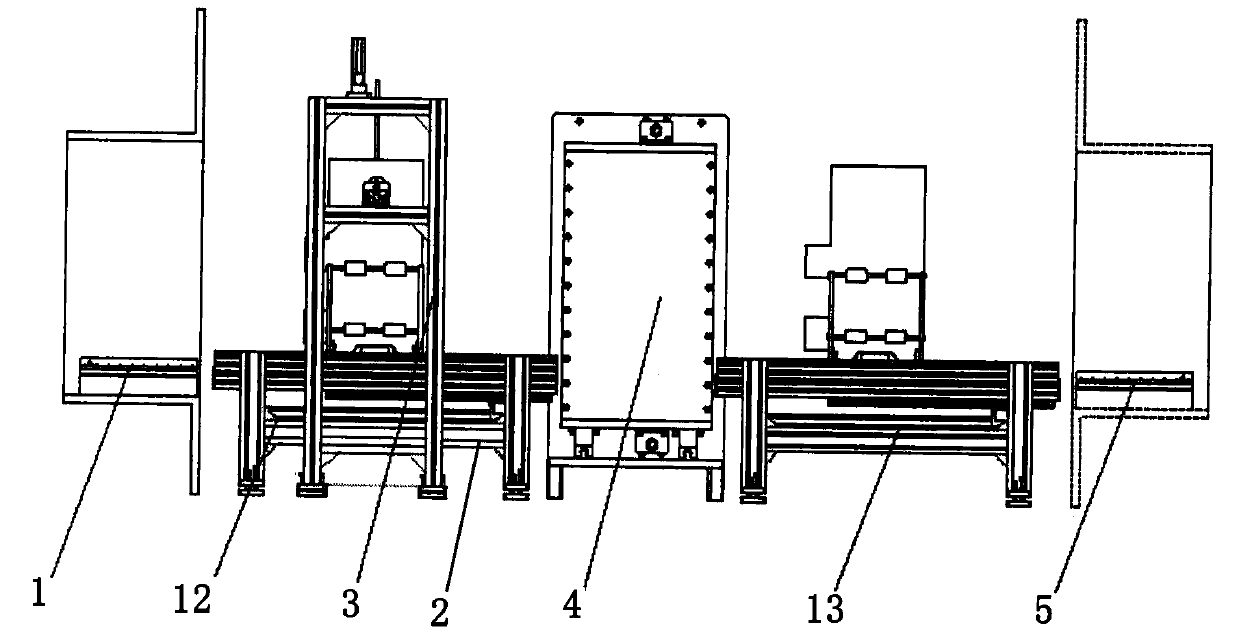

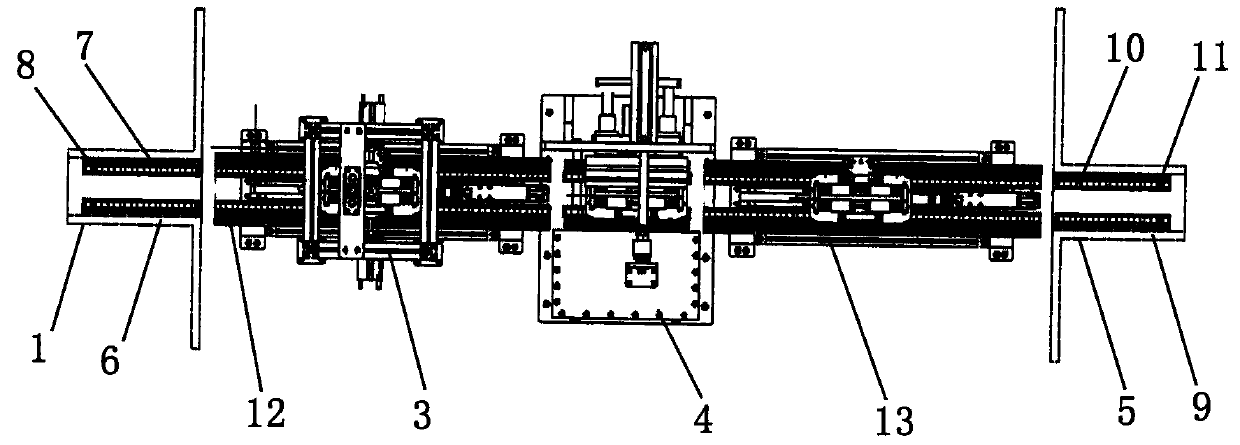

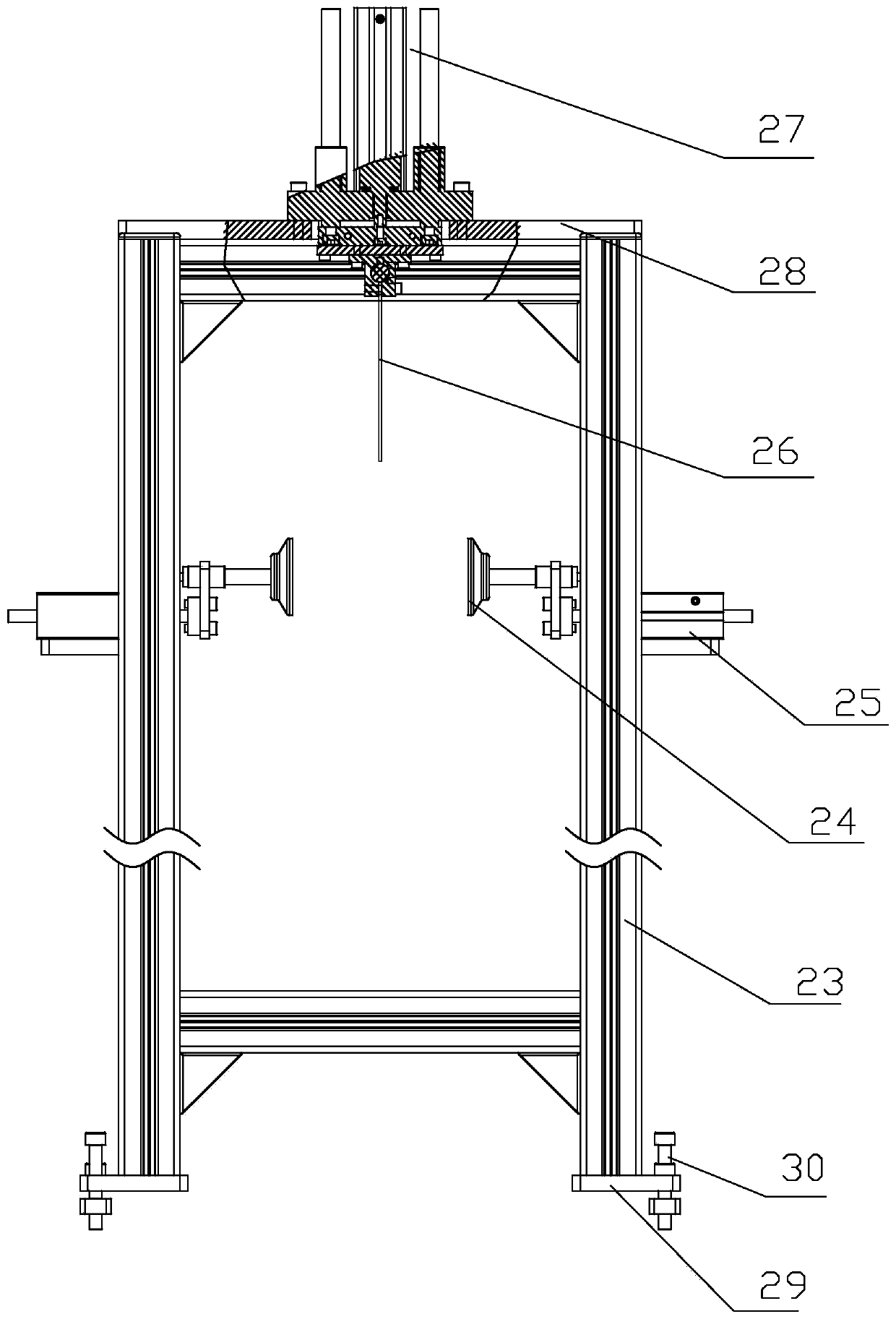

[0039] Refer to the attached figure 1 to attach Figure 9 An automatic production line for liquid injection and pre-sealing of power soft-pack lithium batteries according to the present invention will be described in detail below.

[0040]An automatic production line for liquid injection and pre-sealing of power soft-pack lithium batteries according to the present invention has a structure comprising a feeding device 1, an automatic feeding device 2, an automatic liquid injection device 3, an automatic vacuum pre-sealing device 4 and a feeding device 5. The above-mentioned feeding device 1, automatic liquid injection device 3, automatic vacuum pre-sealing device 4 and unloading device 5 are arranged sequentially from left to right, and the described automatic feeding device 2 is arranged between the feeding device 1 and the unloading device 5 The lower part of the automatic liquid injection device 3 and the automatic vacuum pre-sealing device 4 between.

[0041] Described fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com