Hairbrush inner welding machine wire scraping cutter head

A technology of internal welding machine and cutter head, which is applied in the field of wire scraping cutter head of brush internal welding machine, can solve the problems of wasting manpower, the number of manual wire arrangement, inconvenient production, etc., and achieve the goal of reducing manpower and material resources and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

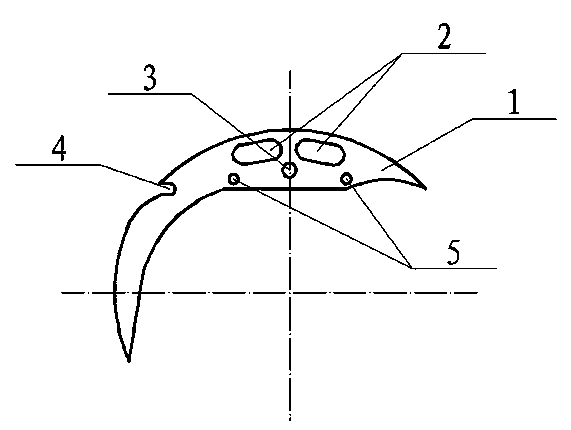

[0018] Referring to the accompanying drawings, the wire scraping cutter head of the brush internal welding machine includes the cutter head 1, the cutter head 1 is crescent-shaped, and the blade of the cutter head 1 has a wire scraping knife edge 4, and the opening direction of the wire scraping knife edge 4 is in one of the cross centerlines. The two sides of the big round hole 3 are provided with positioning holes 5, and the positioning holes 5 are symmetrically distributed on the two sides of the big round hole 3. There are several waist holes 2 on the surface of the cutter head 1. There are two holes 2, which are distributed on both sides of the large circular hole 3, and the cutterhead is cut from 45# steel wire, and the thickness of the cutterhead is greater than 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com