Catalyst for synthesizing ethylenimine as well as preparation method and application thereof

一种乙撑亚胺、催化剂的技术,应用在催化剂活化/制备、化学仪器和方法、非均相催化剂化学元素等方向,能够解决催化剂活性和选择性低、乙撑亚胺选择性降低、副产物增多等问题,达到使用寿命长、改善扩散效果、降低反应温度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

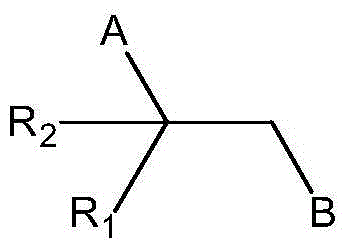

Method used

Image

Examples

Embodiment 1

[0040] In terms of SiO as an oxide 2 :TiO 2 :P 2 o 5 The weight ratio is a stoichiometric configuration of 5:80:15.

[0041] Mix 10g of white carbon black, 160g of titanium dioxide, and 55.7g of diammonium hydrogen phosphate, then add silica sol, the amount of silica sol added is 20% of the mass of titanium dioxide, knead, extrude, dry at 120°C for 6h, and Roast in a furnace at 350°C for 6 hours, then program the temperature at 1°C / min to 650°C for 6 hours to prepare a composite oxide composed of titanium, silicon, and phosphorus.

[0042] Put the composite oxide composed of titanium, silicon and phosphorus into the tubular reactor after cooling, raise the temperature to 150°C, and then use the volume ratio of HF:N 2 =1:5 mixture was fluorinated for 2h to obtain a catalyst carrier. The specific surface area of the carrier was determined by low temperature nitrogen adsorption method to be 42m 2 / g, pore volume 0.22mL / g, average pore diameter 5.6nm.

[0043]According to...

Embodiment 2

[0046] The preparation process in embodiment 2 is basically the same as in embodiment 1, the difference is that according to SiO 2 :TiO 2 :P 2 o 5 The weight ratio is a 10:80:10 stoichiometric configuration. The specific surface area of the catalyst carrier was determined by low temperature nitrogen adsorption method to be 43.2m 2 / g, pore volume 0.21mL / g, average pore diameter 5.8nm.

[0047] According to metal ions as 5.3% load of the carrier mass, the molar ratio of magnesium ions, iron ions, and cesium ions is 8:1:0.1, configure a soluble metal salt solution, impregnate the obtained catalyst carrier for 8 hours, take it out and dry it at 350°C The catalyst was obtained by roasting under nitrogen atmosphere.

[0048] Fill the above catalyst into the reactor with a loading volume of 30mL and heat it to a reaction temperature of 380°C. Nitrogen is used as a protective gas. The gas volume ratio of nitrogen to monoethanolamine is 16. The total space velocity of the gas b...

Embodiment 3

[0050] The preparation process in embodiment 2 is basically the same as in embodiment 1, the difference is that according to SiO 2 :TiO 2 :P 2 o 5 The weight ratio is a 15:80:5 stoichiometric configuration. The specific surface area of the catalyst carrier was determined by low-temperature nitrogen adsorption method to be 46.8m 2 / g, pore volume 0.25mL / g, average pore diameter 6.1nm.

[0051] According to the 0.5% load of metal ions on the mass of the carrier, the molar ratio of magnesium ions, iron ions, and cesium ions is 1:1:0.1, configure a soluble metal salt solution, impregnate the obtained catalyst carrier for 8 hours, take it out and dry it. The catalyst was obtained by roasting in air.

[0052] Fill the above catalyst into the reactor with a loading volume of 30mL, heat it to a reaction temperature of 380°C, use nitrogen as a protective gas, the gas volume ratio of nitrogen to monoethanolamine is 16, and the total gas space velocity in standard state: 3200h -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com