Construction technology with wood surface coated with wooden paint

A technology of wood surface and construction technology, applied in the field of technology, can solve problems such as unreasonable steps, wood corrosion, paint peeling, etc., and achieve the effect of maintaining long-term effectiveness, reducing corrosion and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

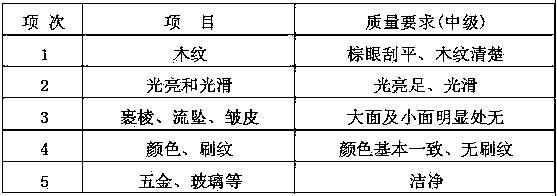

Method used

Image

Examples

Embodiment 1

[0013] Based on the construction technology of smearing wood paint on the wood surface, it includes the following steps:

[0014] (a) First scrape off the dust, traces, glue marks, etc. on the surface of the base layer with a scraper or glass fragments, and then carefully polish it along the wood grain with sandpaper above No. 1, first grind the corners, and then grind the four planes, until smooth;

[0015] (b) Mix large white powder, pine water, and cooked tung oil in a weight ratio of 12:8:1 to form a color oil powder, apply the oil powder evenly on the surface of the wood with cotton silk, rub it into the bristle of the wood, and then wipe it with linen or cotton Wipe the silk, and remove the remaining powder in time at the corners of the line. After the oil powder is dry, use No. 1 sandpaper to lightly polish along the wood grain.

[0016] (c) Mix gypsum powder and cooked tung oil in a weight ratio of 20:7, and add pigments to make a gypsum-colored putty. After the putty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com