Fully automatic curved crown retainer production equipment

A technology for production equipment and retainers, applied in mechanical equipment, bearing components, shafts and bearings, etc., can solve the problems of high risk, poor production operation safety, low production efficiency, etc., to achieve precise positioning and movement, and good production stability , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

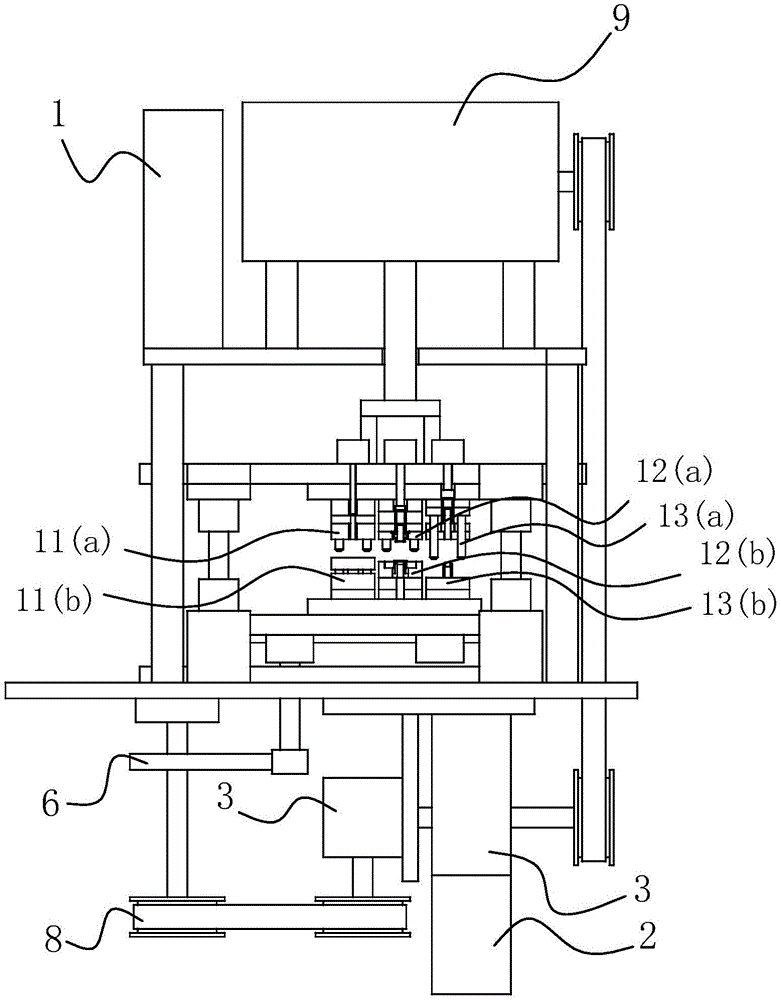

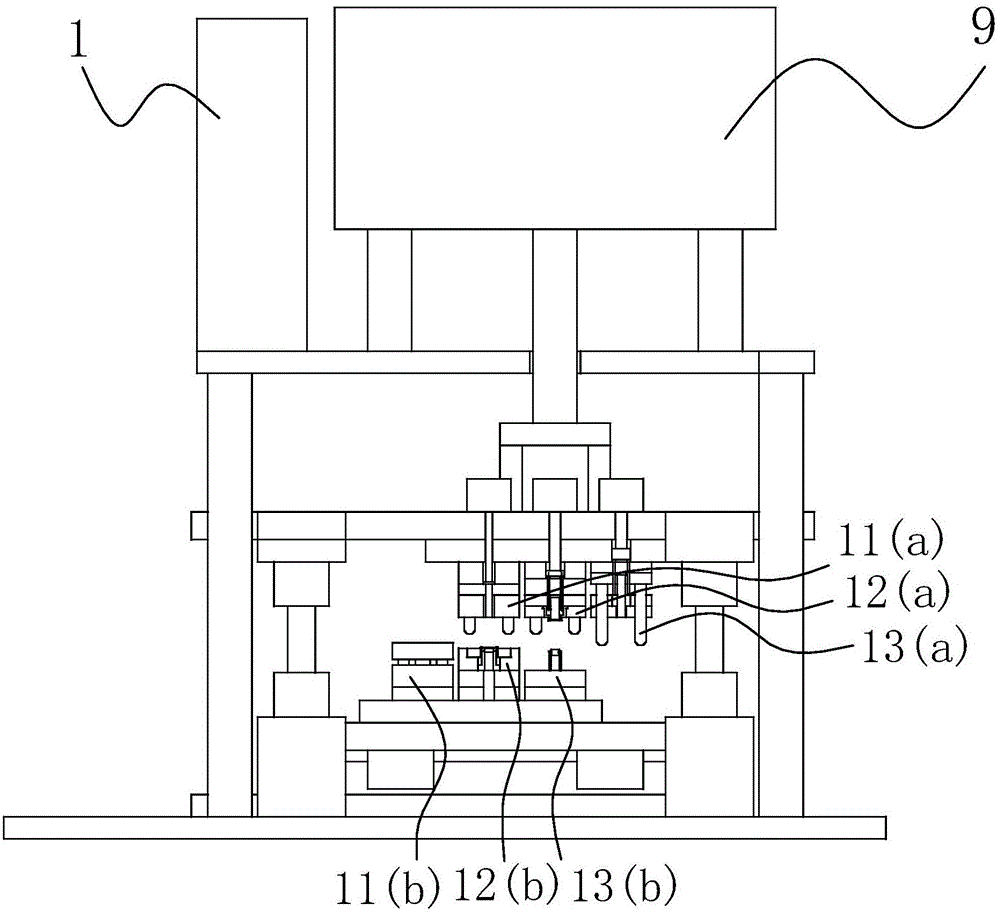

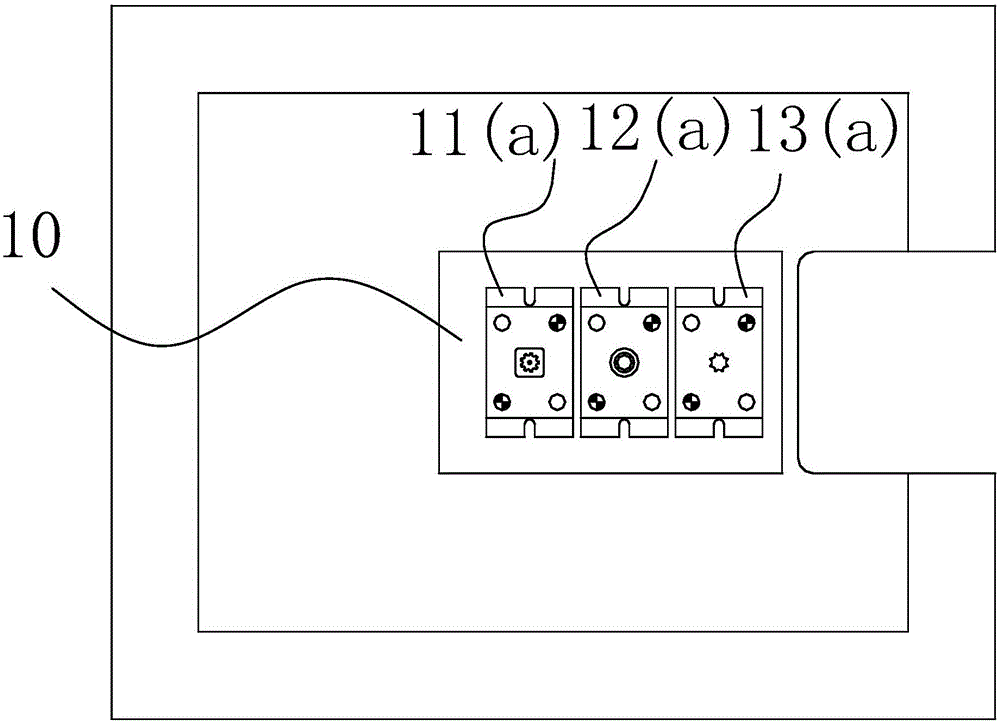

[0022] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention fully automatic curved crown retainer production equipment,

[0023] The full-automatic curved crown retainer production equipment of the present invention includes a control center 1, a motor 2, a reducer 3, a feeding mechanism, a front and rear automatic transmission mechanism 4, and an up and down automatic feeding and forming mechanism 5, and the front and rear automatic transmission mechanism 4 includes a cam 6 and The lower mold 7 and the upper and lower automatic material taking forming mechanism 5 include an axle 8, a crankshaft 9 and an upper mold 10.

[0024] On the one hand, the control center 1 is connected to the motor 2 to control the operation of the motor 2. On the other hand, the control center 1 is connected to the feeding mechanism to control the feeding of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com