A Gravity Transporter for Orchards in Large Slope Mountains

A large slope, conveyor technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that cannot meet the transportation needs of remote and large slope mountain orchards, reduce labor intensity, reduce labor costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

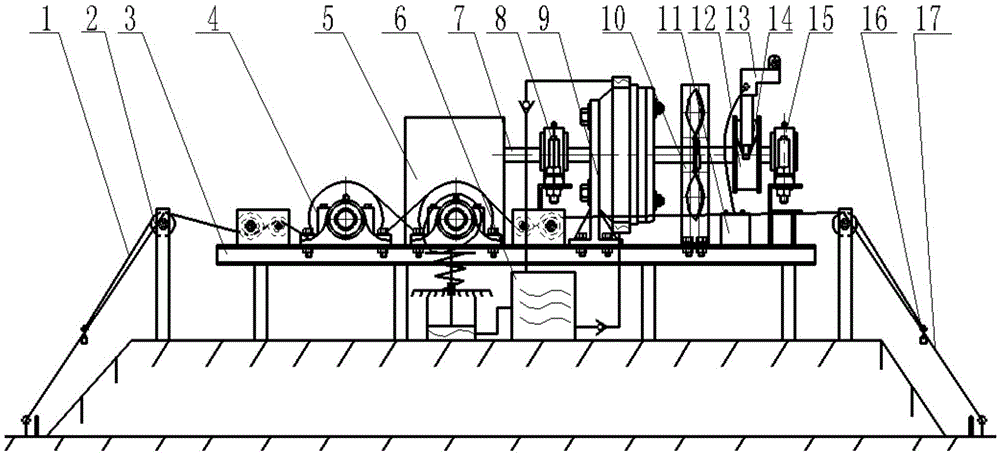

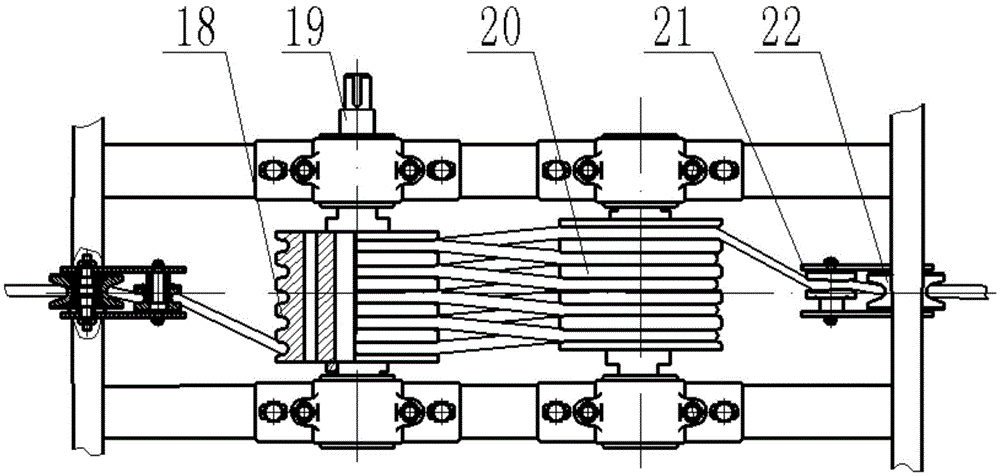

[0024] Such as figure 1 , figure 2 Shown as figure 1 As shown, a gravity conveyor for a large-slope mountain orchard includes a main engine, a wire rope track 17, a driving wire rope 1, and a transport box 16. The main frame 3 is fixed on the top of the mountain, and a gravity transmission device 4, a speed increasing box 5, a radiator 6, and an adaptive damping device 9 are mounted on it. The steel wire rope track 17 is composed of steel wire ropes fixed at the upper and lower ends.

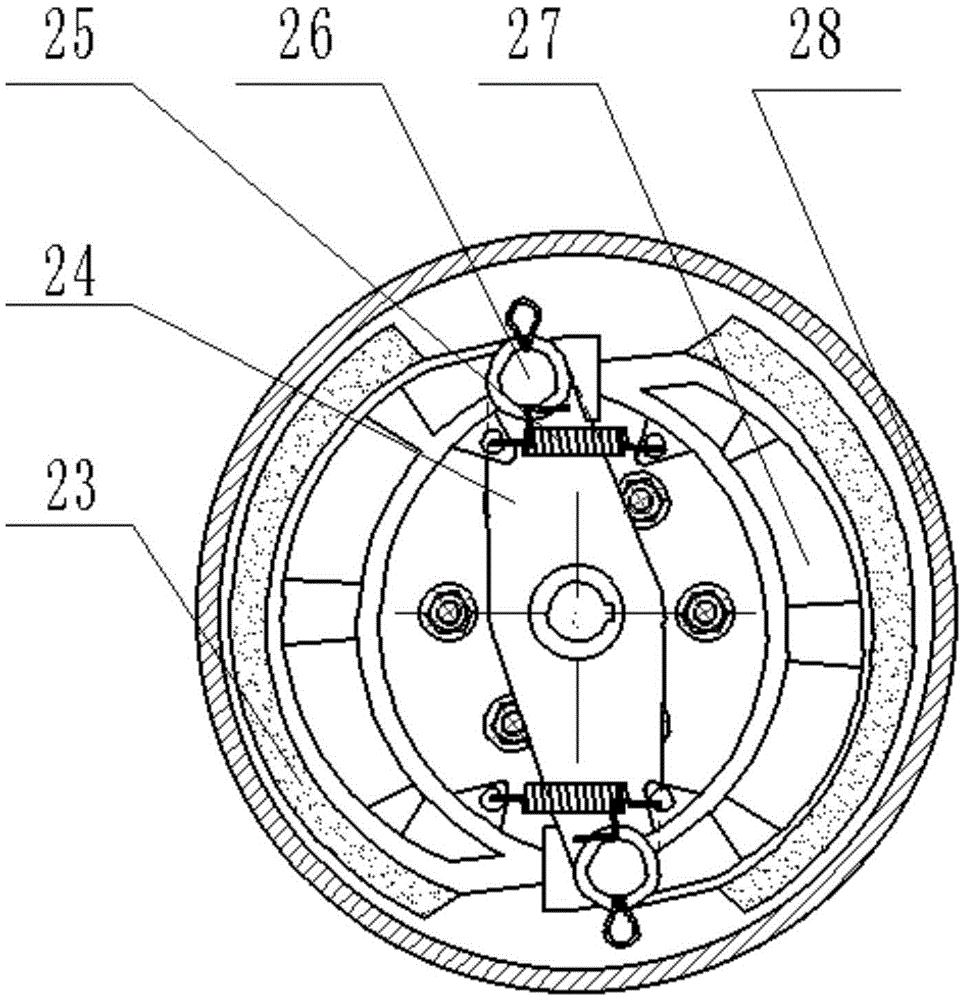

[0025] The supporting base plate 24, the brake drum 12 and the cooling fan 10 are fixedly connected to the high-speed brake shaft 7 through fixed keys.

[0026] The box body 45 is welded by angle steel, the bottom is equipped with a bottom parking remote control 44 composed of an ultrasonic sensor and a single-chip microcomputer, and the top is equipped with a rolling pulley 46, which slides down along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com