Oil and gas pipeline corrosion and leakage monitoring and early warning system and method based on OFDR optical fiber sensing

A monitoring and early warning, oil and gas pipeline technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve leakage early warning monitoring system, pipeline corrosion and other problems, achieve real-time, accurate monitoring of engineering information, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

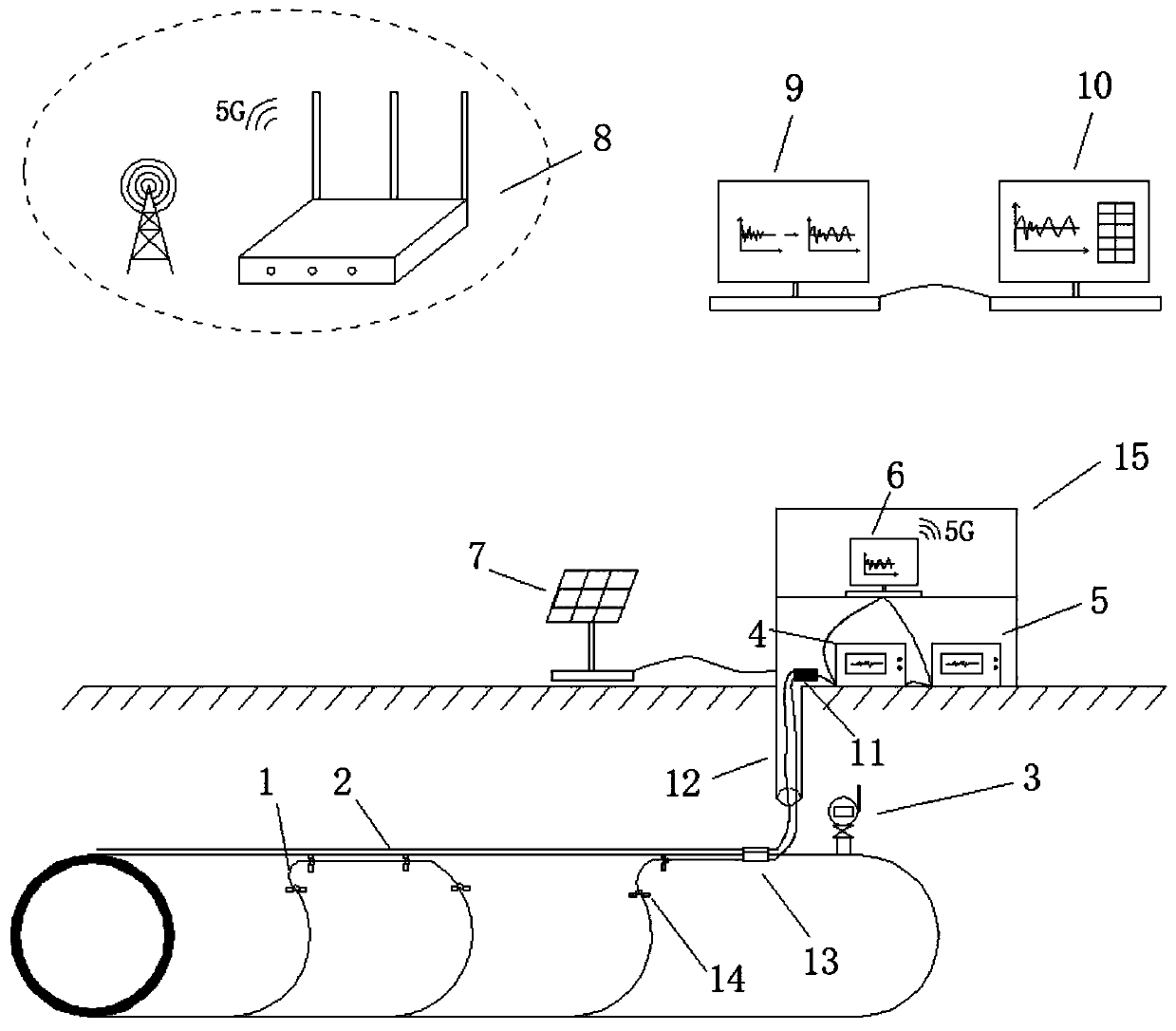

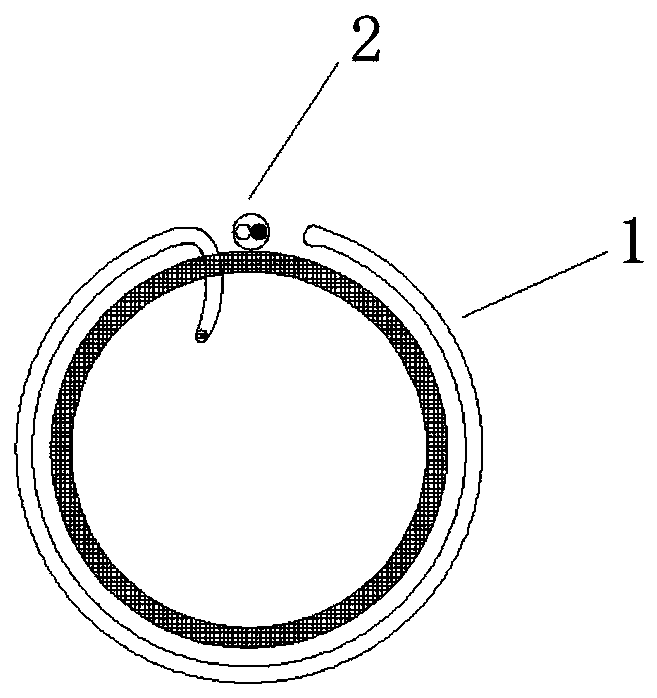

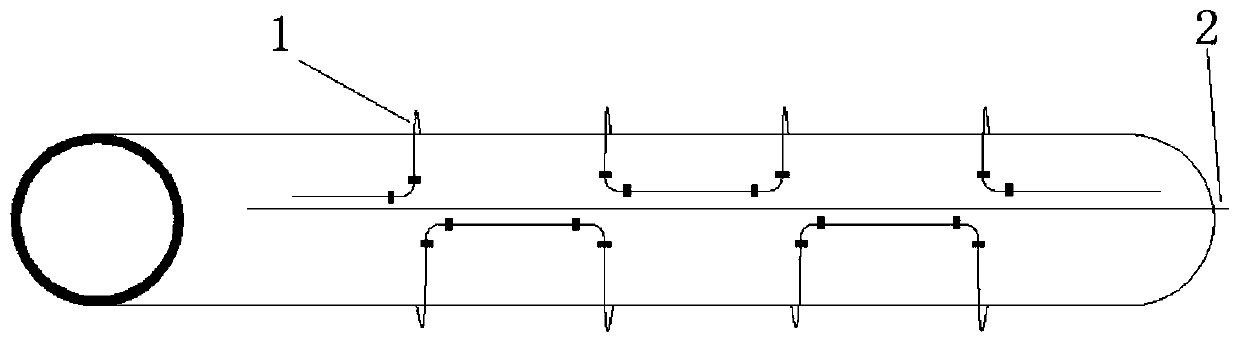

[0037] Such as figure 1As shown, the monitoring and early warning system of the present invention includes a distributed optical fiber strain sensor 1, a distributed optical fiber temperature sensor 2, a pipeline internal pressure sensor 3, a first OFDR optical fiber data automatic acquisition device 4, a second OFDR optical fiber data automatic acquisition device 5, and a road surface Base station 15, road base station information display and transmission system 6, solar energy supply system 7, 5G signal transmission system 8, optical fiber data processing and analysis system 9, and display and early warning system 10. Wherein the optical fiber data processing and analysis system 9 and the display warning system 10 are located in the remote control room. Both the distributed optical fiber strain sensor 1 and the distributed optical fiber temperature sensor 2 are connected to the first OFDR optical fiber data automatic acquisition device 4 and the second OFDR optical fiber dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com