Method for adhering slag onto electric furnace for smelting titanium slag

An electric furnace smelting and titanium slag technology, which is applied in the field of electric furnace smelting titanium slag, can solve the problems of damage to the slag layer in the molten pool section, bricks seen on the upper part of the furnace wall, and poor slag effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

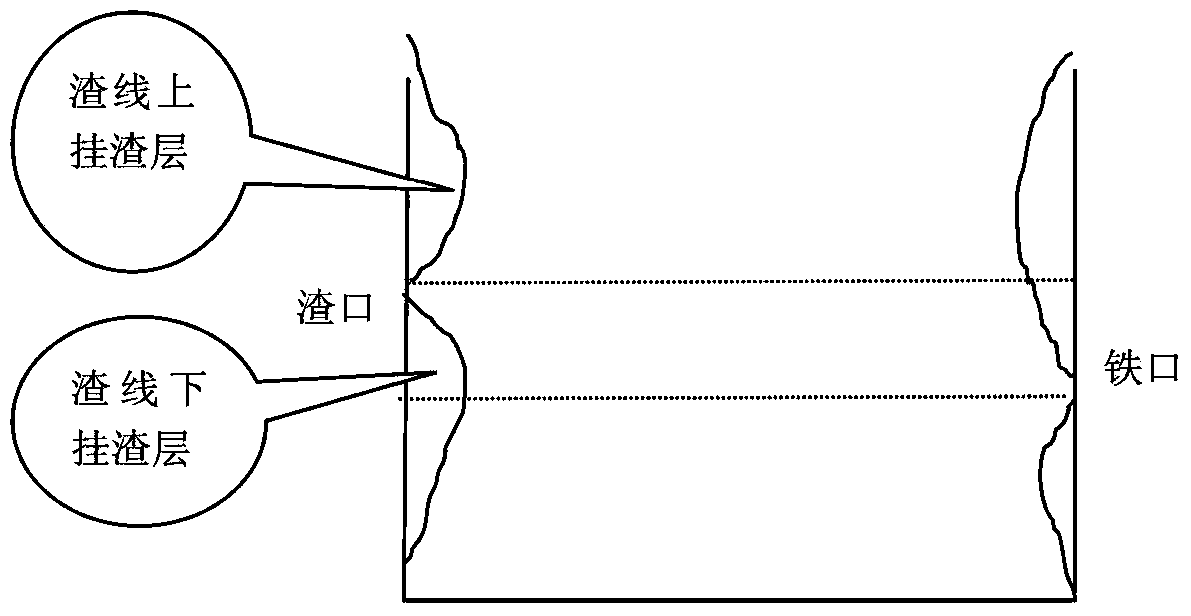

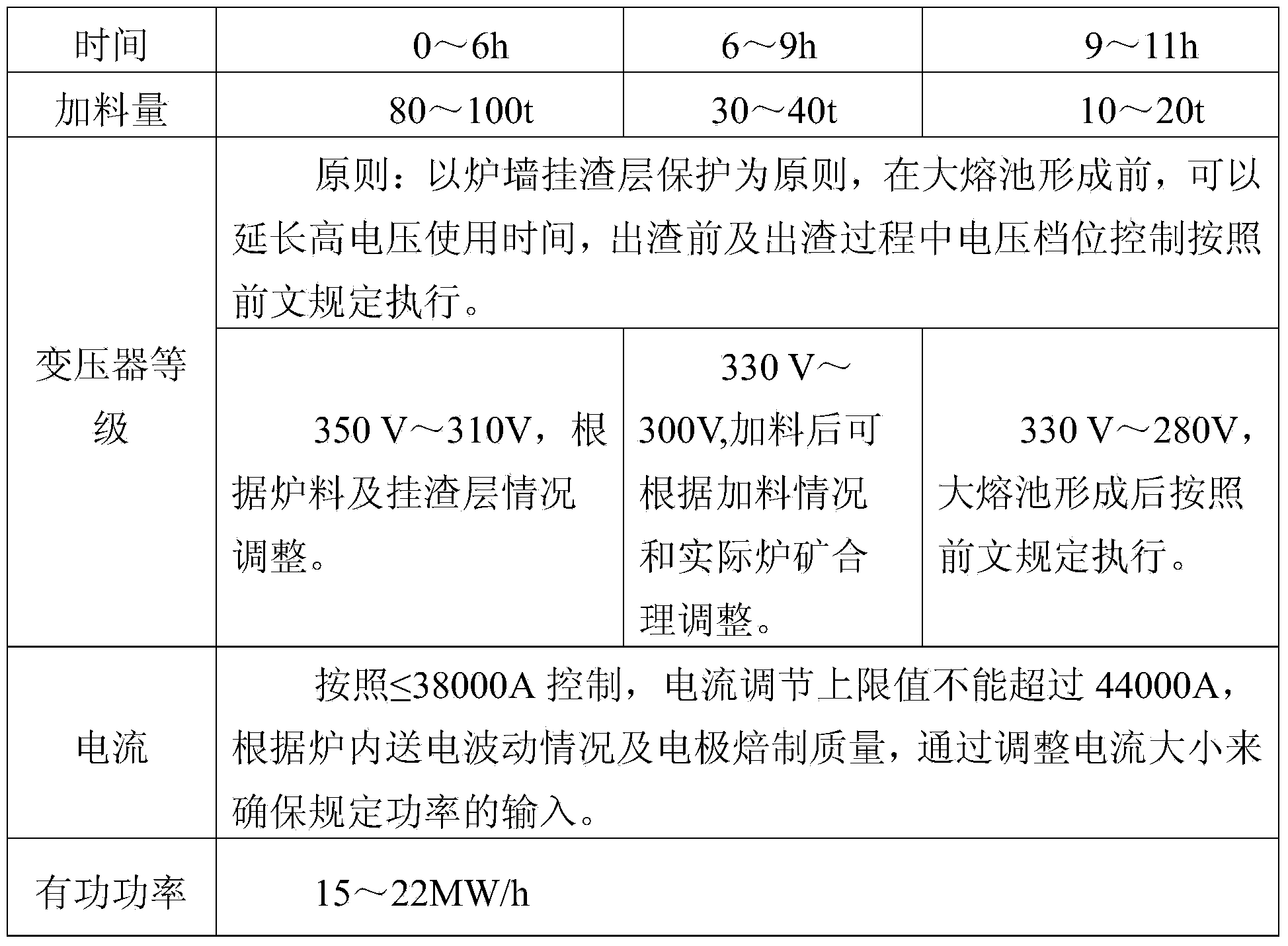

[0012] The smelting process of electric furnace smelting titanium slag can be roughly divided into three stages: reduction melting, deep reduction and overheating. The three main stages are briefly described below.

[0013] (1) Reductive melting stage: after the charge is preheated, a reduction reaction occurs, thereby melting begins. At this time, melting and reduction proceed simultaneously, and the melting of the charge gradually expands outward from around the electrodes until the charge between the electrodes is completely melted to form a molten pool. Marks the end of the reductive melting phase.

[0014] (2) Deep reduction stage: The slag formed after melting the charge still contains 10%-12% FeO. When producing high-reduction titanium slag, the residual FeO still needs to be further deeply reduced into iron.

[0015] (3) Superheated furnace stage: After the deep reduction, in order to ensure smooth furnace, sometimes it is still necessary to heat the melt to fully sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com