35crmnsi steel heat treatment method to eliminate the second type of temper brittleness and improve toughness and 35crmnsi steel

A heat treatment method and temper brittleness technology, which is applied in the field of 35CrMnSi steel, can solve the problems of sharp drop in impact toughness, product quality decline, and increased production costs, and achieve the effects of eliminating temper brittleness, improving quality, and facilitating implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

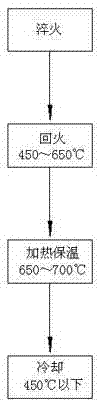

[0026] A kind of heat treatment method that 35CrMnSi steel eliminates the second type of temper brittleness and improves toughness, it comprises the steps:

[0027] Step 1, quenching: quenching the 35CrMnSi steel;

[0028] Step 2, Tempering: Temper the 35CrMnSi steel quenched in Step 1 in the temperature range of 450-650°C. The tempering time is calculated according to the effective cross-section of the forging for every 100 mm of heat preservation for 2 hours, and the time is extended by half. At the same time The total number shall not be less than 4 hours; the specific calculation formula is: t=D / 100×2×2, where t is the tempering time in hours, and D is the effective section of the forging in millimeters;

[0029] Step 3, heating and heat preservation: transfer the 35CrMnSi steel obtained by tempering in step 3 to a heating environment of 650-700°C for heat preservation until the forging uniformly reaches the heating temperature, and the time required for the forging to uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com