Patents

Literature

33results about How to "Simple heat treatment method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

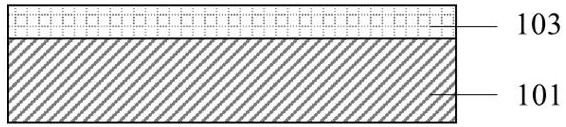

Metal super-hydrophobic surface and preparation method thereof

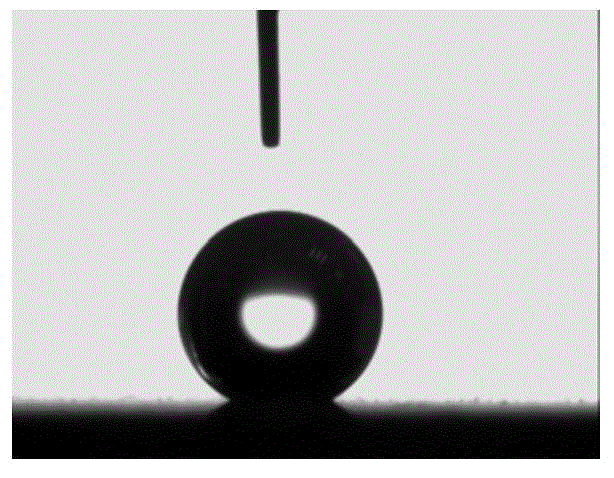

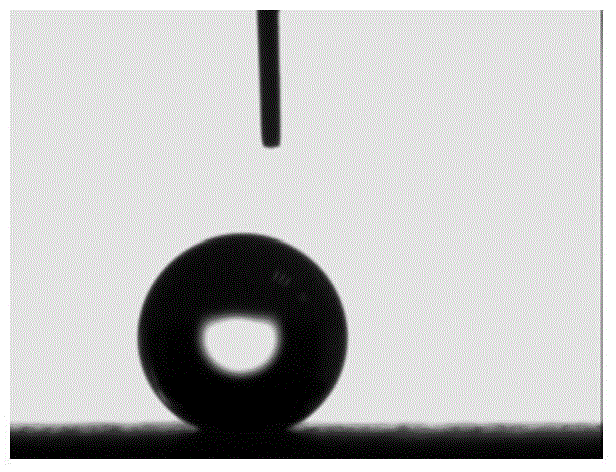

The invention relates to a metal super-hydrophobic surface and a preparation method thereof. The preparation method comprises following two steps: firstly, electroplating method is adopted, traditional Watts electroplate liquid is taken as a base electroplate liquid, conductive metal base materials such as stainless steel, copper, aluminium alloy, and magnesium aluminum alloy, are taken as a negative electrode, and copper sheets are taken as a positive electrode so as to prepare a nickel coating layer; and secondly, an obtained electroplated surface and an ethanol solution containing fluorosilane are delivered into a heating furnace for heat treatment, and an obtained sample is subjected to washing and blow drying so as to obtain the surface with super-hydrophobicity on metal workpieces. The preparation method of the metal super-hydrophobic surface is simple; cost is low; and the preparation method is convenient for industrialized application. Contact angle of the obtained metal super-hydrophobic surface is more than 155 DEG, and rolling angel is less than 10 DEG; the metal super-hydrophobic surface possesses excellent super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance; the preparation method is suitable for obtaining the metal super-hydrophobic surfaces with super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance on the surfaces of a plurality of metal base materials with complex shapes and large area.

Owner:SOUTH CHINA UNIV OF TECH

Aluminum product surface super-hydrophobic film and making method thereof

InactiveCN104131322AExcellent superhydrophobicityImprove self-cleaning functionAnodisationWear resistanceRolling angle

The invention relates to an aluminum product surface super-hydrophobic film and a making method thereof. The method comprises the following steps: 1, placing an aluminum product in an electrolyte as an anode, and anodizing under a current density of 0.1-0.5A.cm<-2> for 1-20min to obtain an anodized aluminum surface; and 2, immersing the anodized aluminum surface in an ethanol solution containing silicon fluoride for at least 1min, carrying out heat treatment on the obtained workpiece at 100-200DEG C for 5-40min, and naturally cooling to obtain the aluminum product surface super-hydrophobic film. The making method of the super-hydrophobic surface has the advantages of simplicity, low cost and easy industrialization. The super-hydrophobic surface made in the invention has a contact angle exceeding 150DEG, a roll angle of below 10DEG and stable hydrophobicity. The surface has the advantages of very good super-hydrophobic function, very good automatic cleaning function, excellent wear resistance and excellent corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH

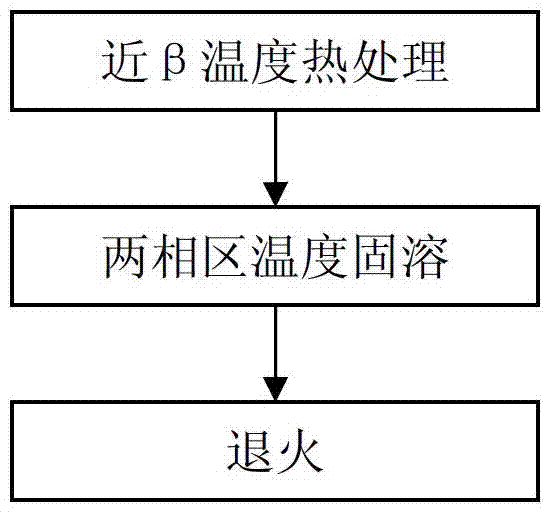

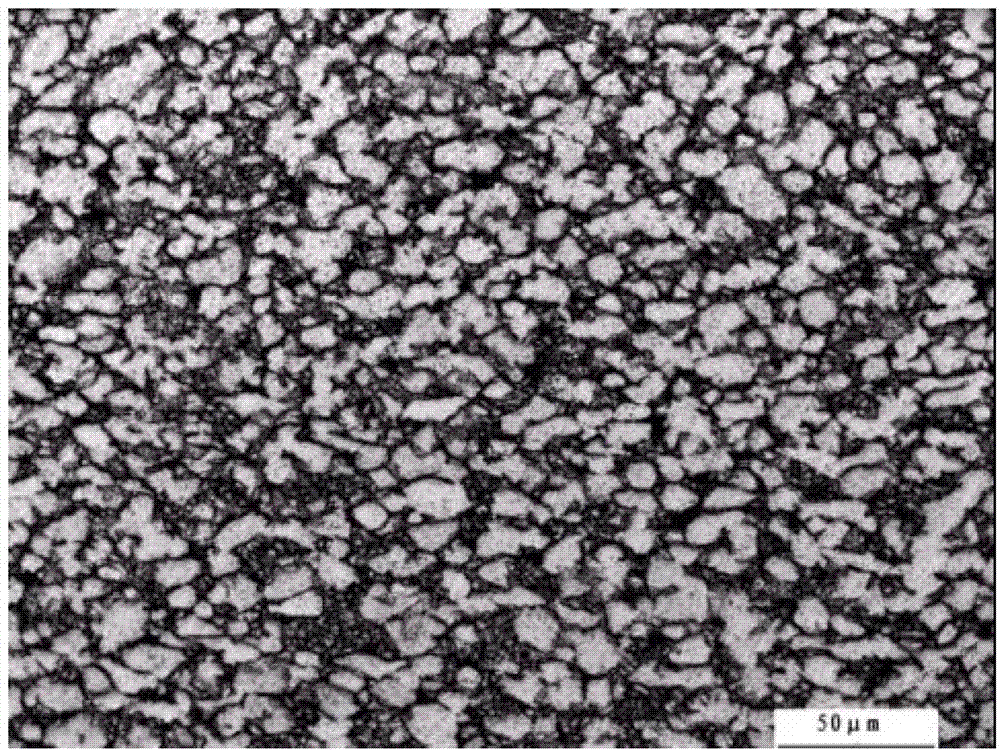

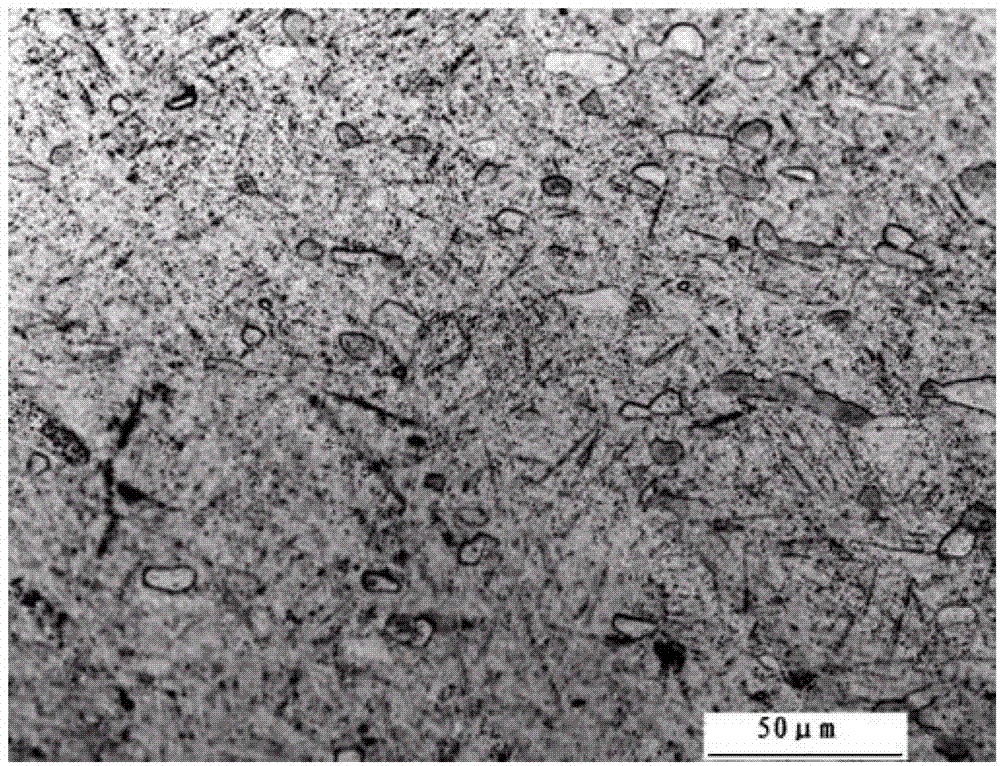

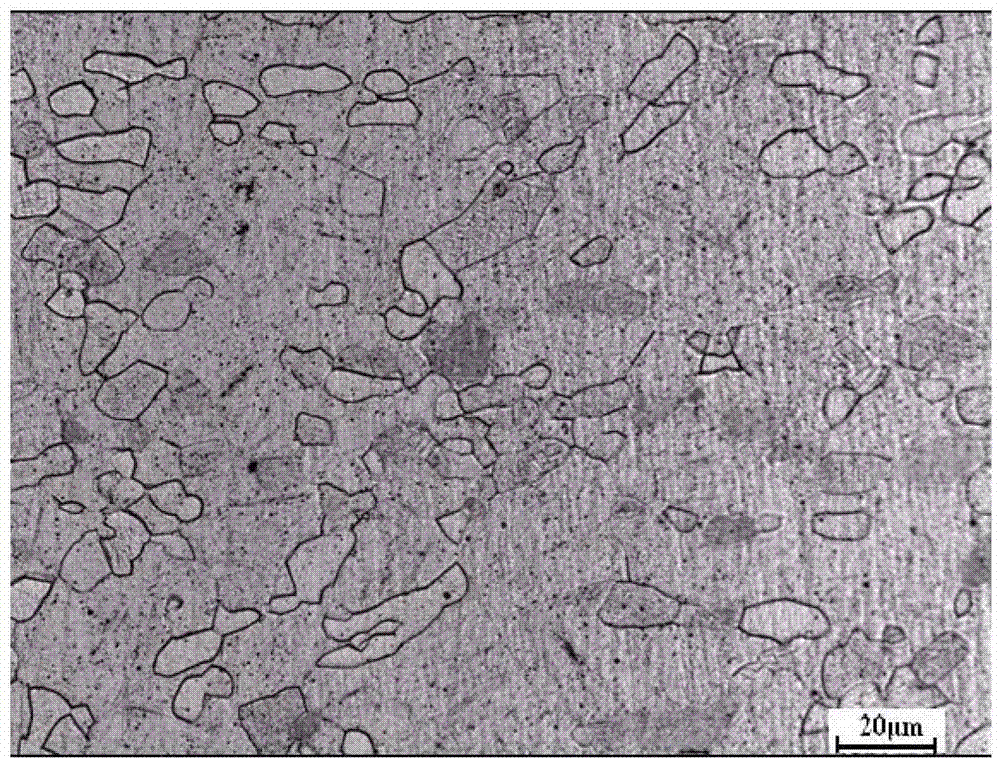

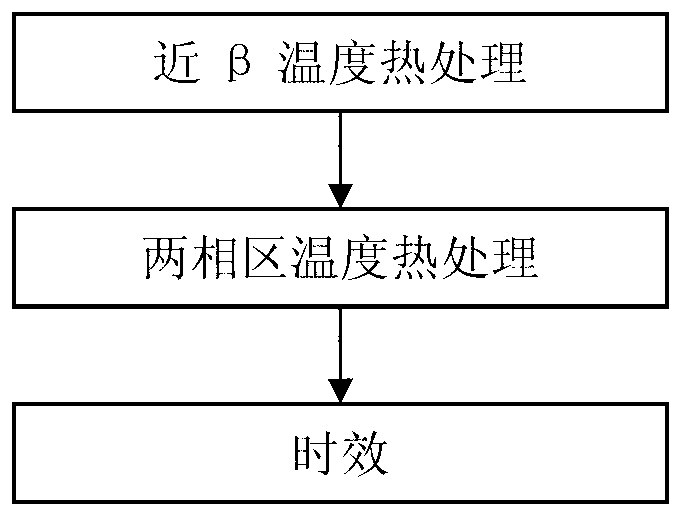

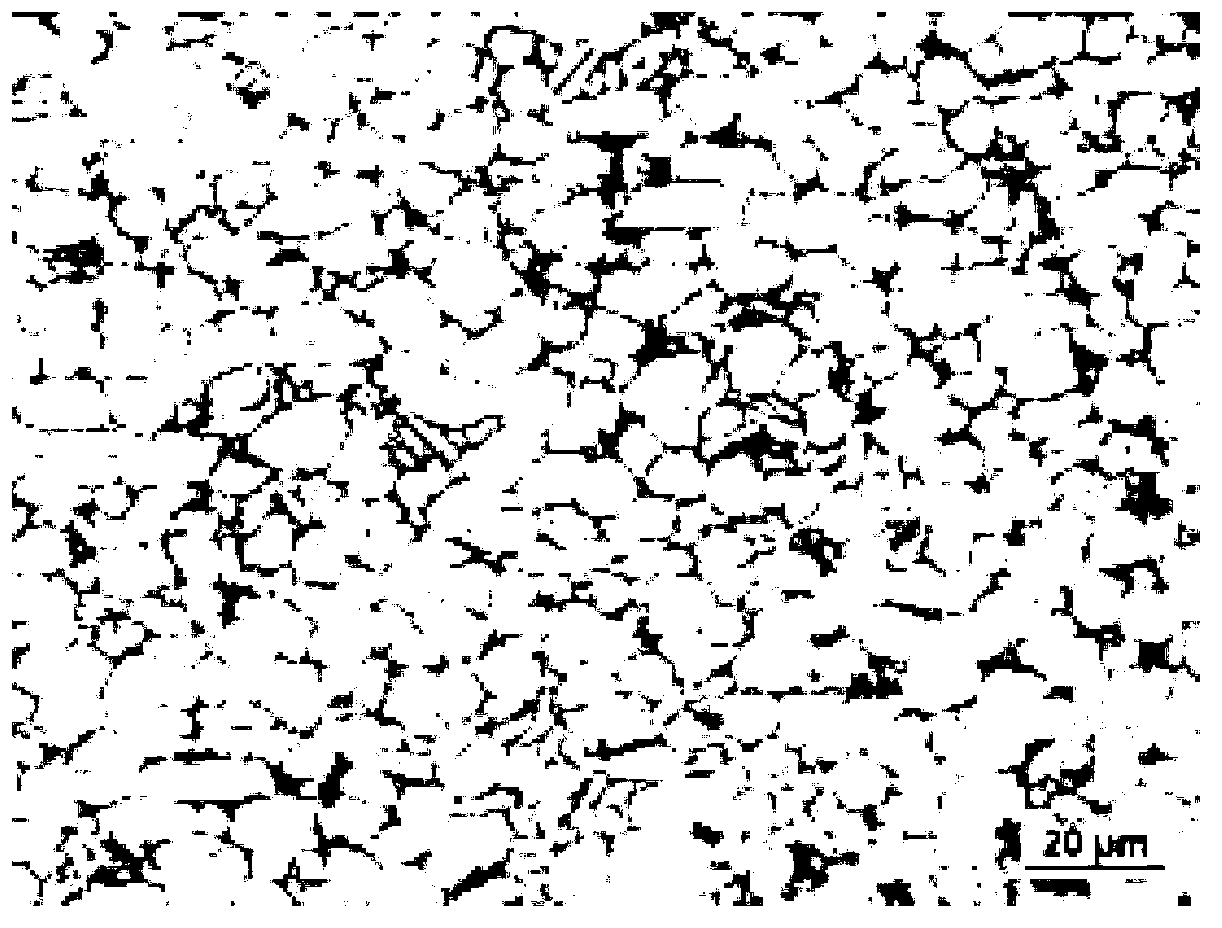

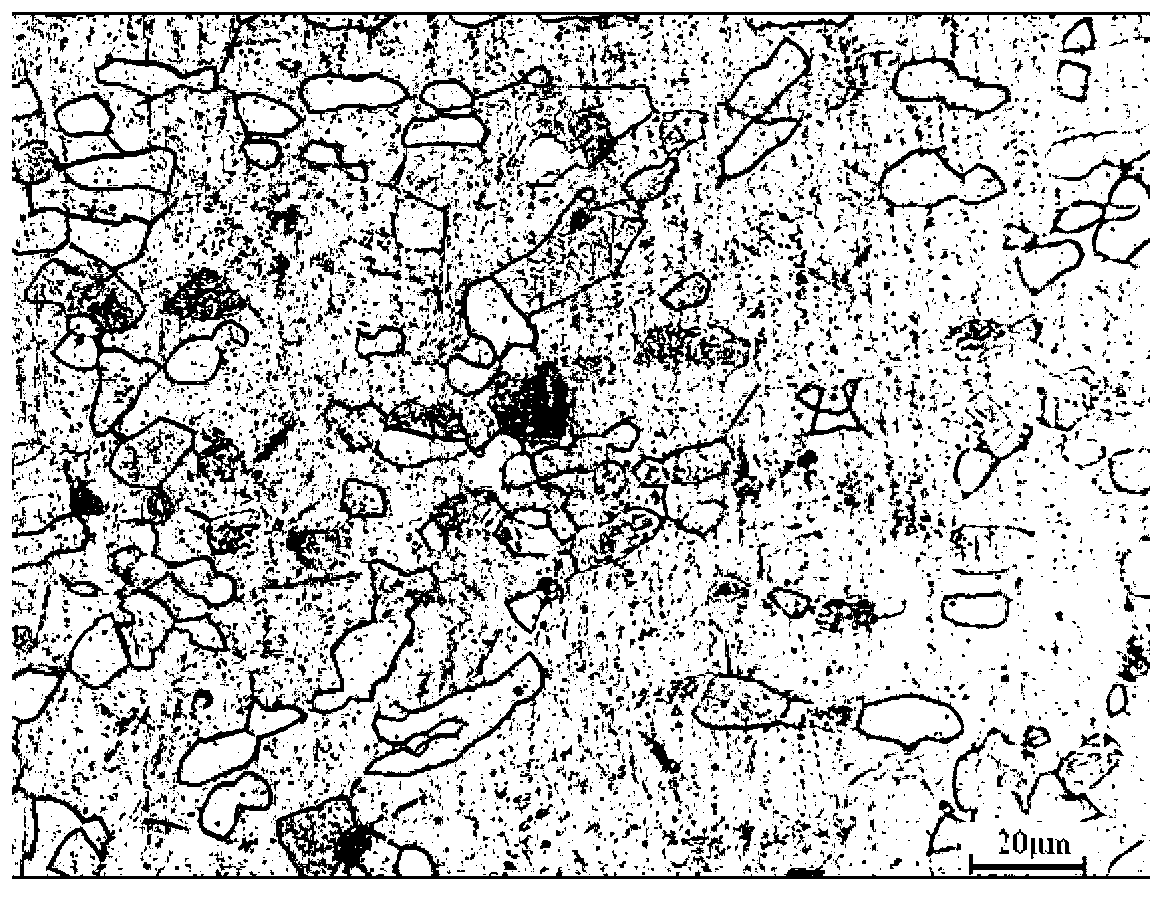

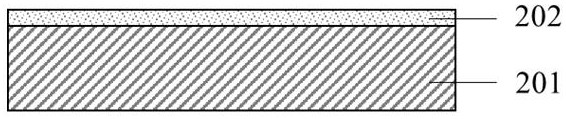

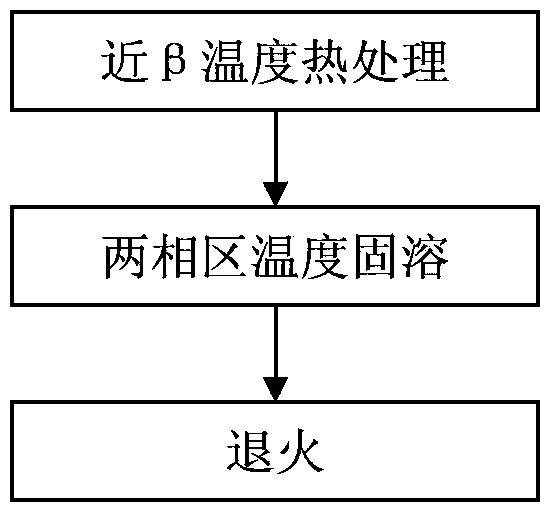

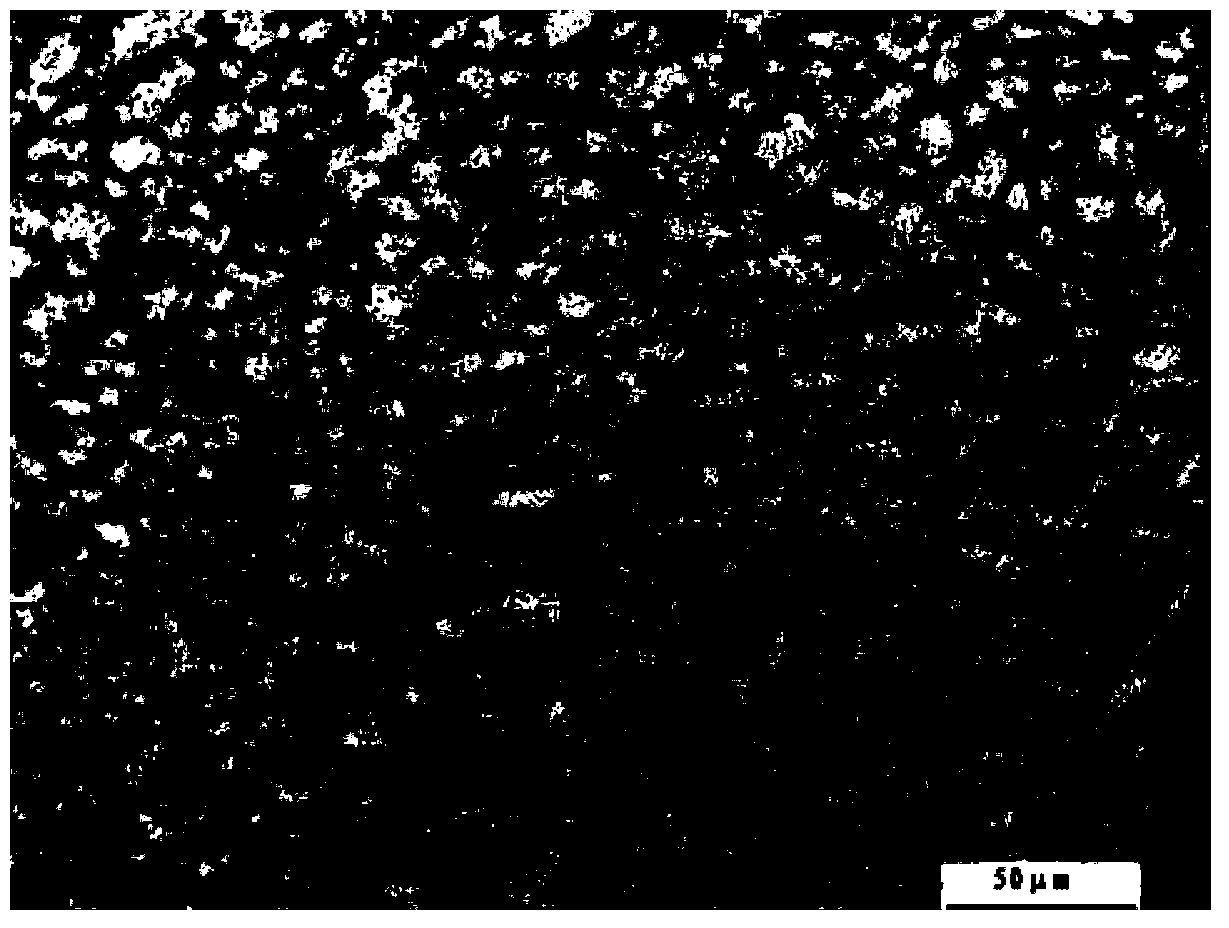

Method for obtaining tri-state tissue from titanium alloy

ActiveCN102758161ANo deformation temperature rise effectEasy temperature controlTest sampleThermal deformation

The invention discloses a method for obtaining a tri-state tissue from a titanium alloy, and is characterized in that through thermal treatment at near beta temperature, a test sample tissue is changed to an alpha isometric+martensite; through temperature solution in a two-phase region, the test sample tissue is changed to an alpha isometric+alpha silver+martensite; and the titanium alloy with the tri-state tissue is obtained through annealing. According to the invention, near beta thermal deformation is not required, a deformation temperature rise effect cannot be generated, the temperature is easy to control, and an initial isometric tissue of the titanium alloy can become a duplex tissue without special pretreatment. The method, provided by the invention, is simple and easy, and wide in application range, and can be applied to thermal treatment of titanium alloy parts, which are produced by methods, such as rolling, extrusion, machining and the like, so that the tri-state tissue is obtained. In particular for complicated titanium components, locally complicated components or large components, after a near clean form of the components is obtained through machining, the tri-state tissue is obtained through the method provided by the invention.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

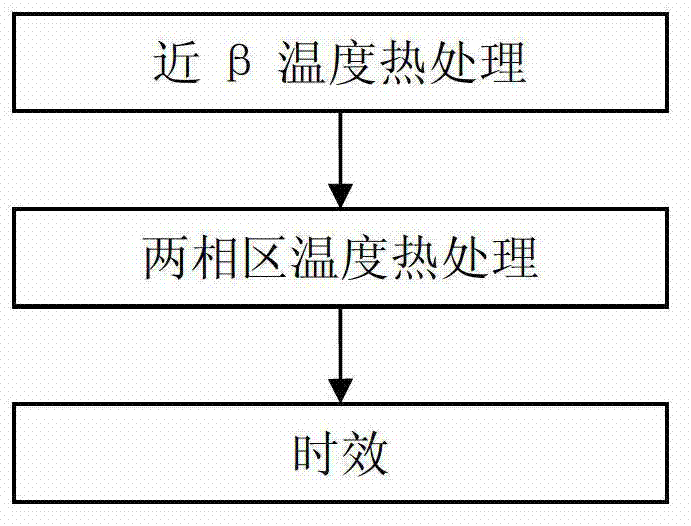

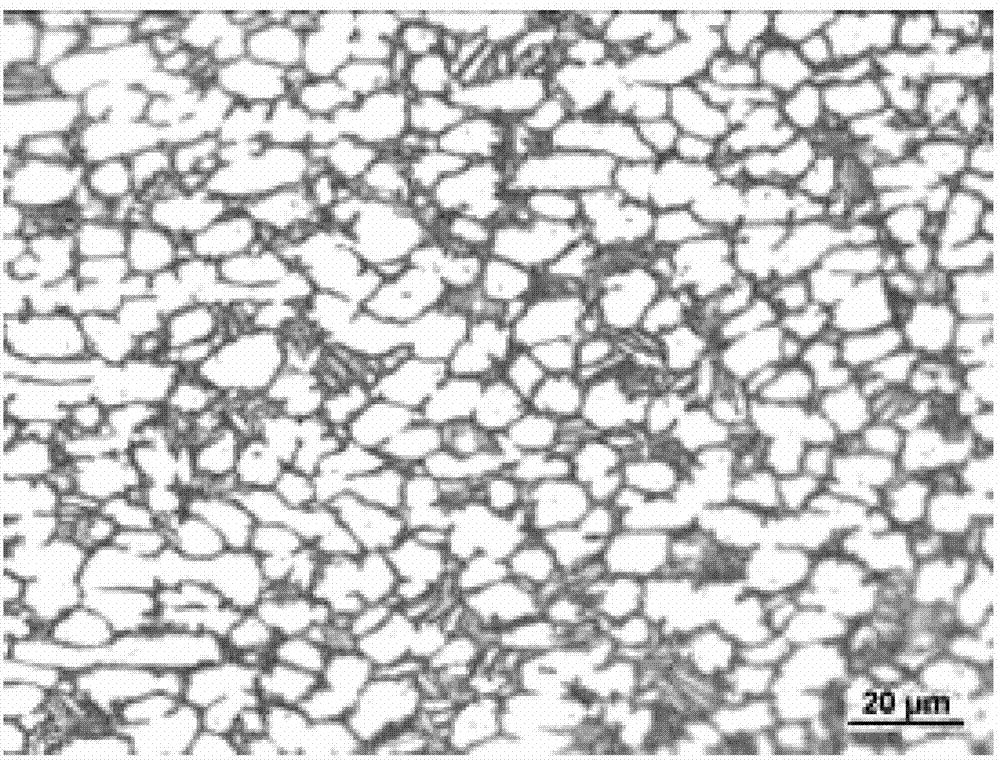

Method for acquiring tri-modal microstructure in near-alpha titanium alloy

The invention relates to a method for acquiring a tri-modal microstructure in a near-alpha titanium alloy. Near-beta temperature heat treatment is carried out to change the sample microstructure into alpha-equiaxial+martensite; two-phase region temperature heat treatment is carried out to change the sample microstructure into alpha-equiaxial+alpha sliver+beta-rotation; and aging treatment is carried out to obtain the titanium alloy with tri-modal microstructure. The invention does not need near-beta thermal deformation, does not generate deformation temperature rise effect, can easily controlthe temperature, and does not need to carry out special pretreatment on the equiaxial-structure near-alpha titanium alloy to acquire the duplex microstructure. The invention is simple and easy to implement, has wide application range, and is suitable for heat treatment on near-alpha titanium alloy parts manufactured by rolling, extrusion, machining and other formation methods to acquire the tri-modal microstructure. Especially for the titanium alloy complex components, partial complex components or large-size components, after processing the near net shape of the component, the method can be utilized to acquire the tri-modal microstructure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

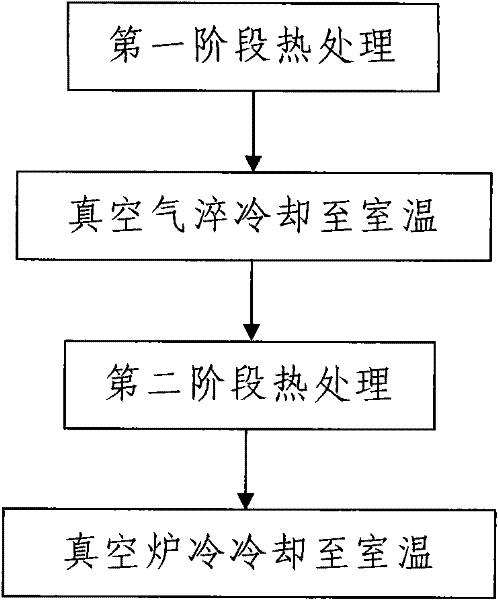

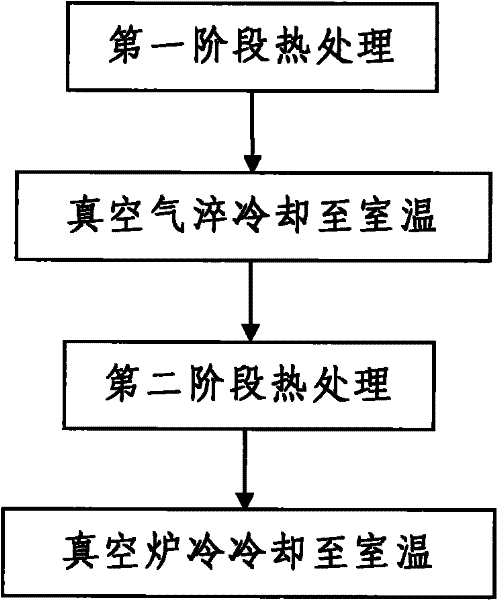

Thermal treatment method for improving mechanical property of titanium alloy strip

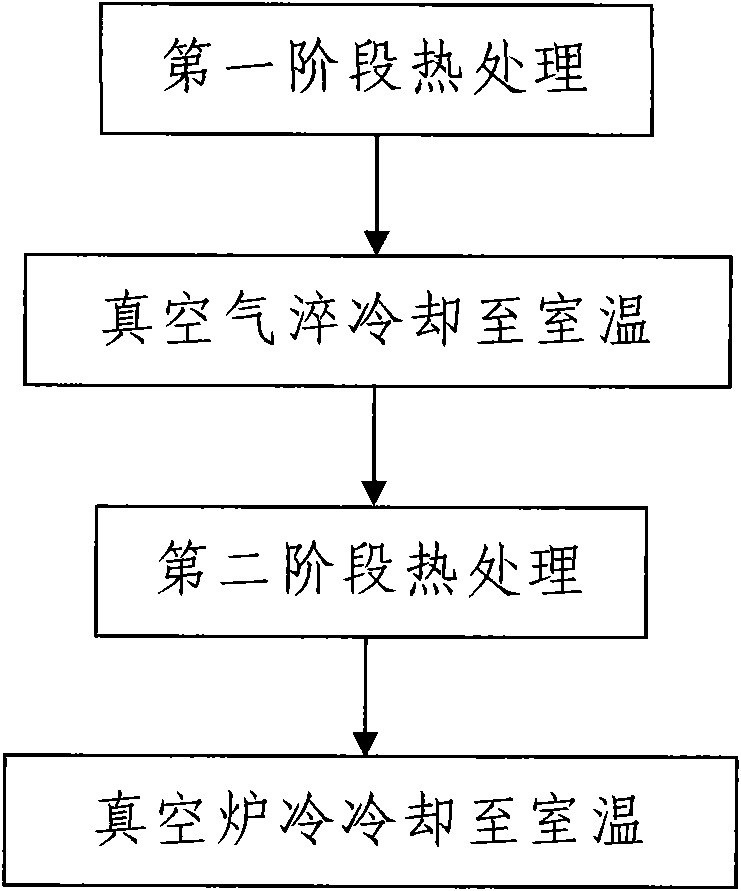

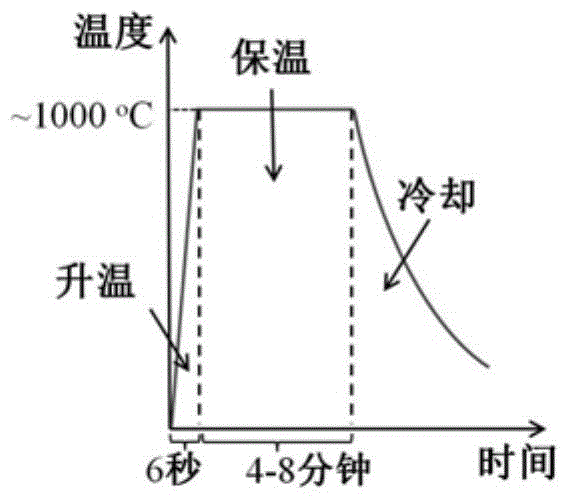

The invention discloses a thermal treatment method for improving mechanical property of a titanium alloy strip, which comprises the following steps of: 1, a first stage of thermal treatment: performing the first stage of thermal treatment on the treated titanium alloy strip by adopting a vacuum thermal treatment furnace, wherein the heating temperature is 780 to 820 DEG C, the heat preservation time is 10 to 20 minutes and the cooling mode is vacuum gas quenching; and a second stage of thermal treatment: performing the second stage of thermal treatment on the treated titanium alloy strip after the first stage of thermal treatment by adopting the vacuum thermal treatment furnace, wherein the heating temperature is 460 to 540 DEG C, the heat preservation time is 6 to 10 hours and the cooling mode is vacuum furnace cooling. The method has the advantages of reasonable design, simple thermal treatment, simple and convenient operation and good thermal treatment effect; the mechanical property of the treated titanium alloy strip is greatly improved; and the method fully meets the technical requirements of the TB2 titanium alloy strip for aviation and spaceflight for high strength, high toughness, high modulus and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

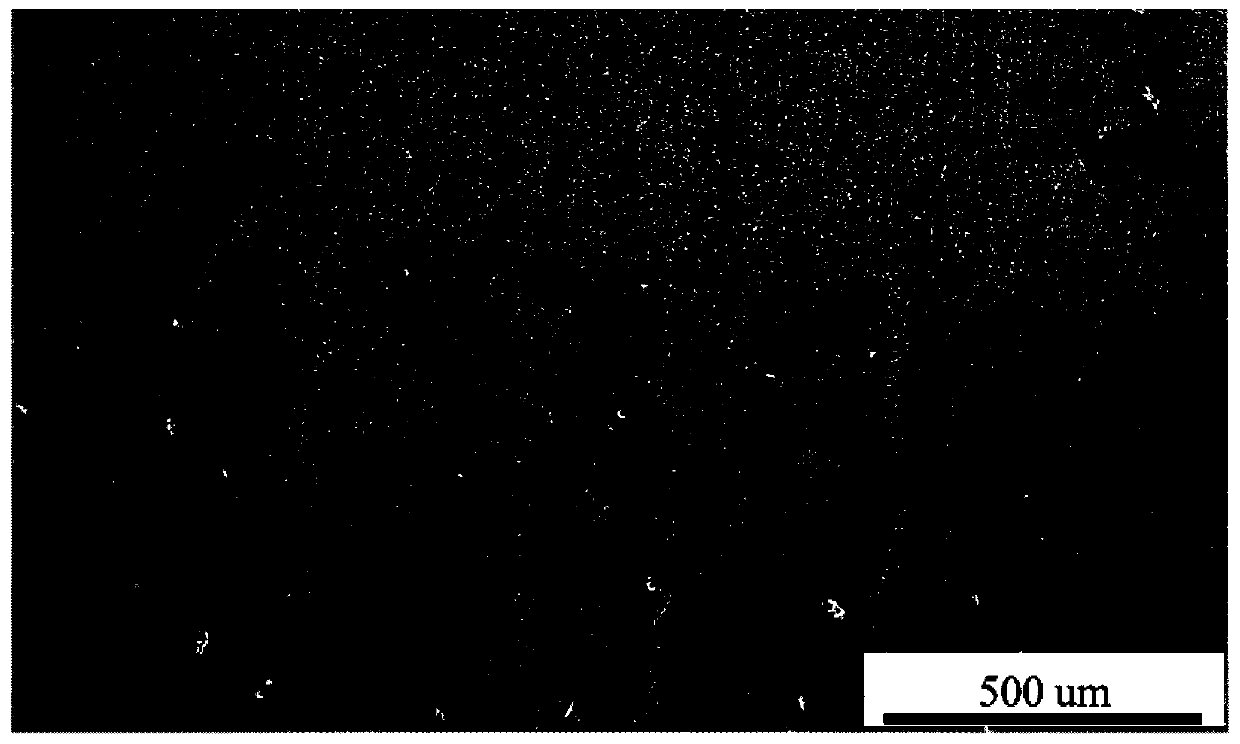

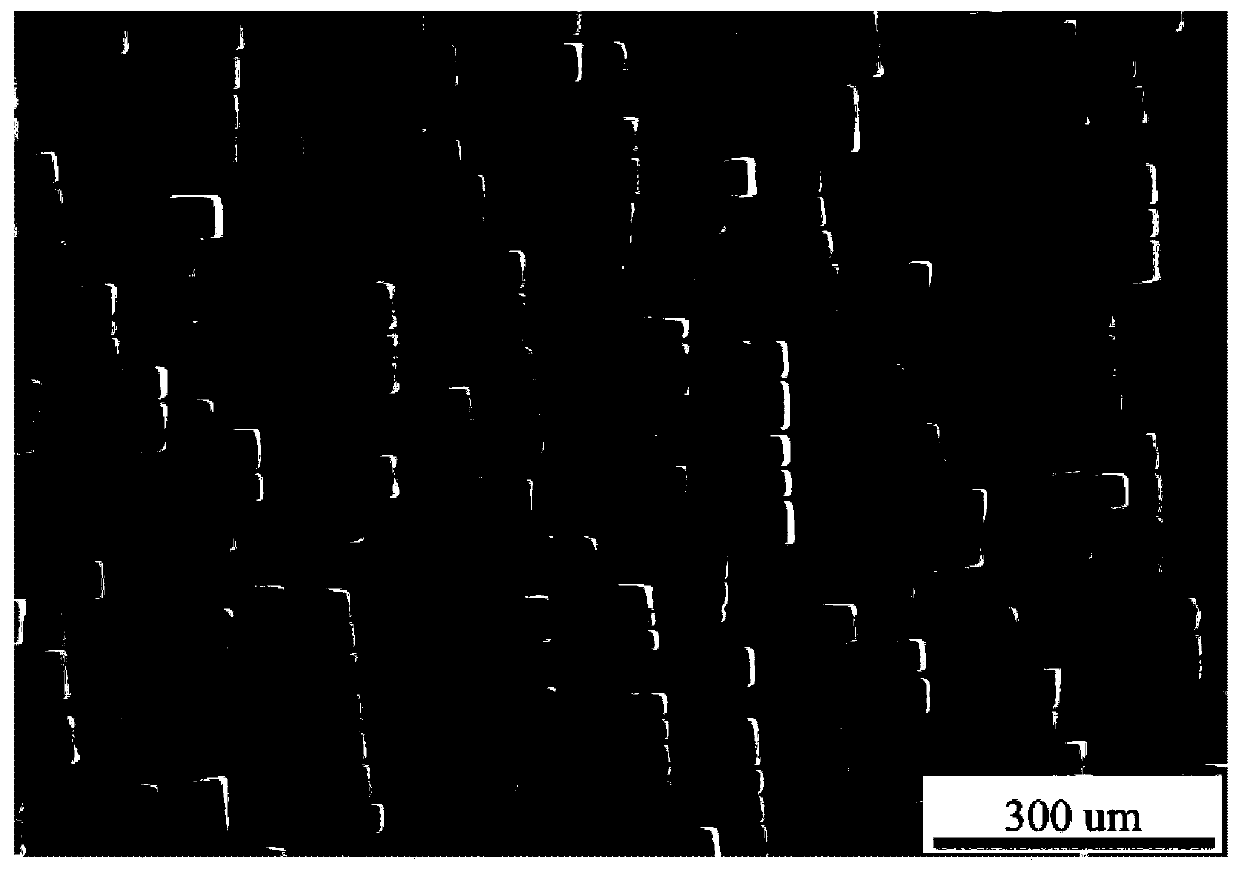

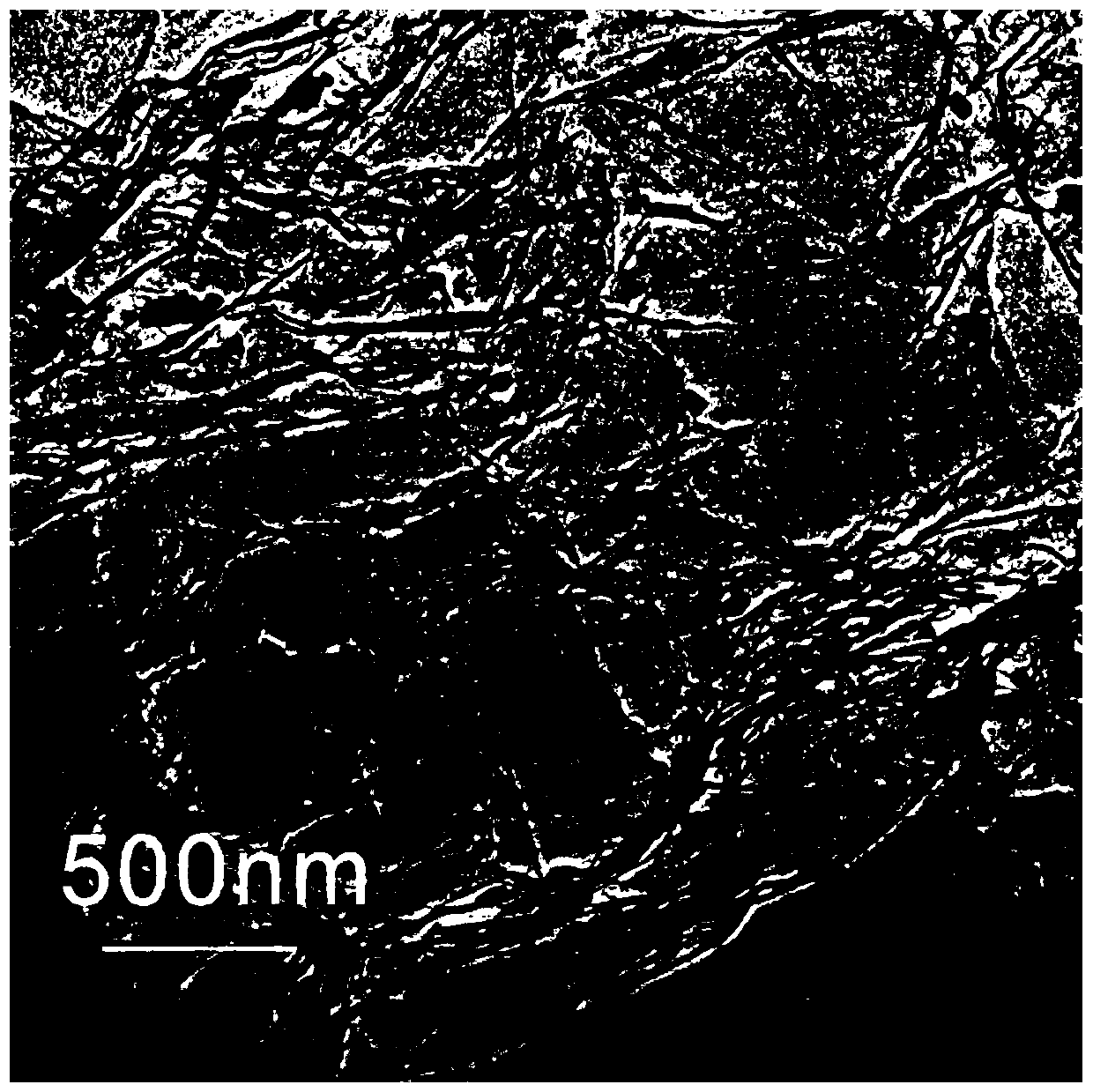

Method for direct and rapid preparation of single-layer graphene on SiO2/Si substrate

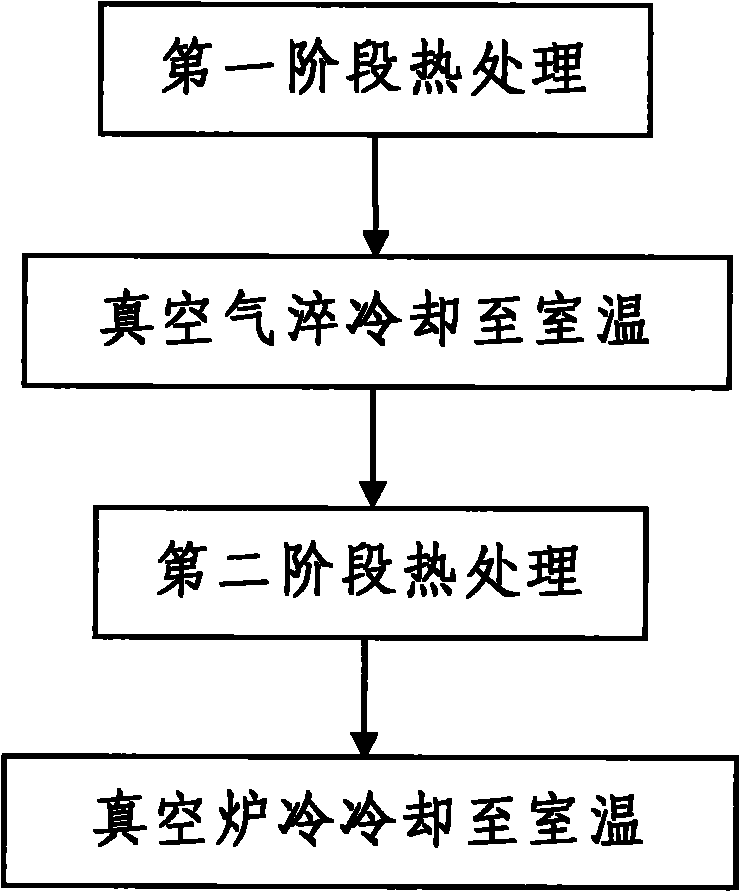

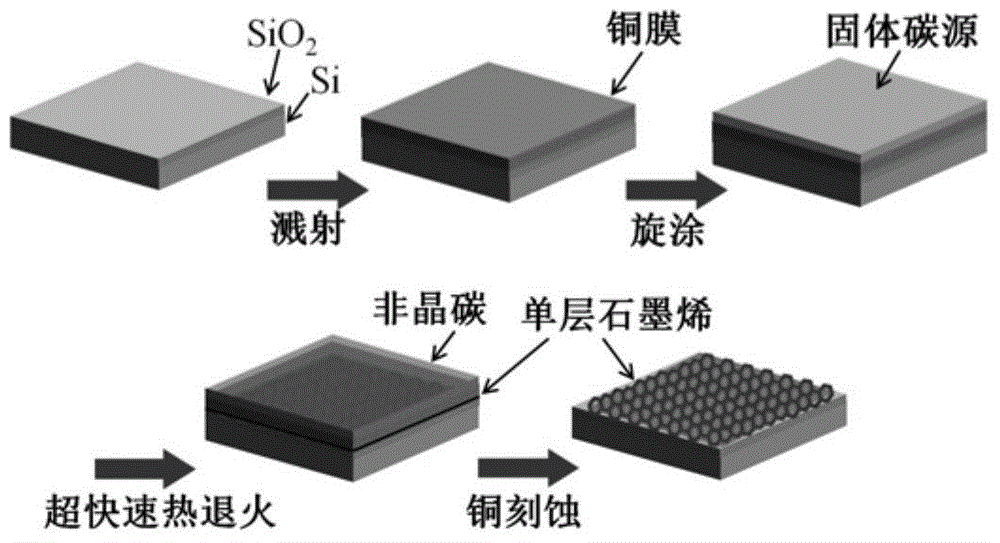

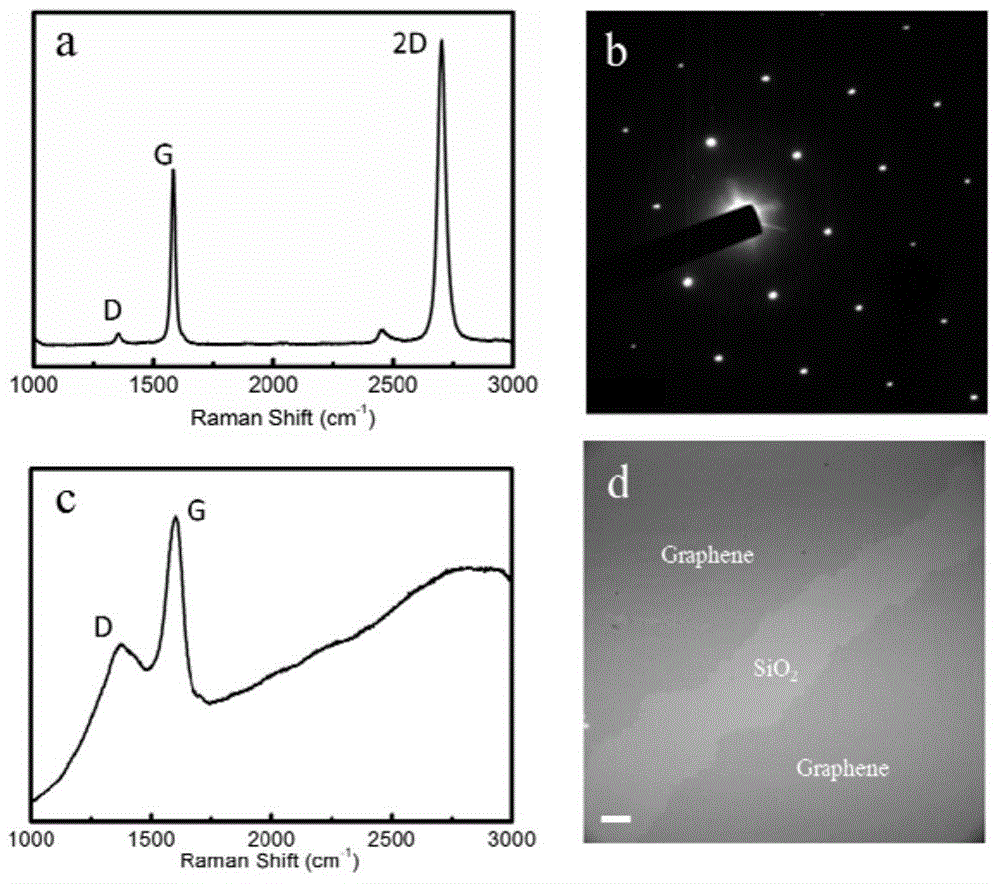

The invention discloses a method for direct and rapid preparation of single-layer graphene on a SiO2 / Si substrate. The method comprises the following main steps: depositing a layer of a crystallized metal catalytic material film on the SiO2 / Si substrate and then uniformly coating the surface of the metal catalytic material film with a solid carbon source; carrying out high-temperature treatment on the previously-obtained sample by using simple rapid heat treatment technology, wherein in the process of rapid high-temperature heat treatment, a part of the carbon source on the surface of the metal catalytic material film is diffused onto the surface of SiO2 through metal grain boundaries and forms single-layer graphene under active catalysis of metal, and the rest part of amorphous carbon is left on the surface of the film; and finally, carrying out simple metal dissolving so as to obtain single-layer graphene with SiO2 / Si as a substrate. With the method provided by the invention, large-area high-quality single-layer graphene can be directly obtained on the SiO2 / Si substrate. The method has simple and rapid preparation process, is compatible with current microelectronic process, does not need transfer of the substrate and is beneficial for device processing and application of graphene.

Owner:HANSHAN NORMAL UNIV

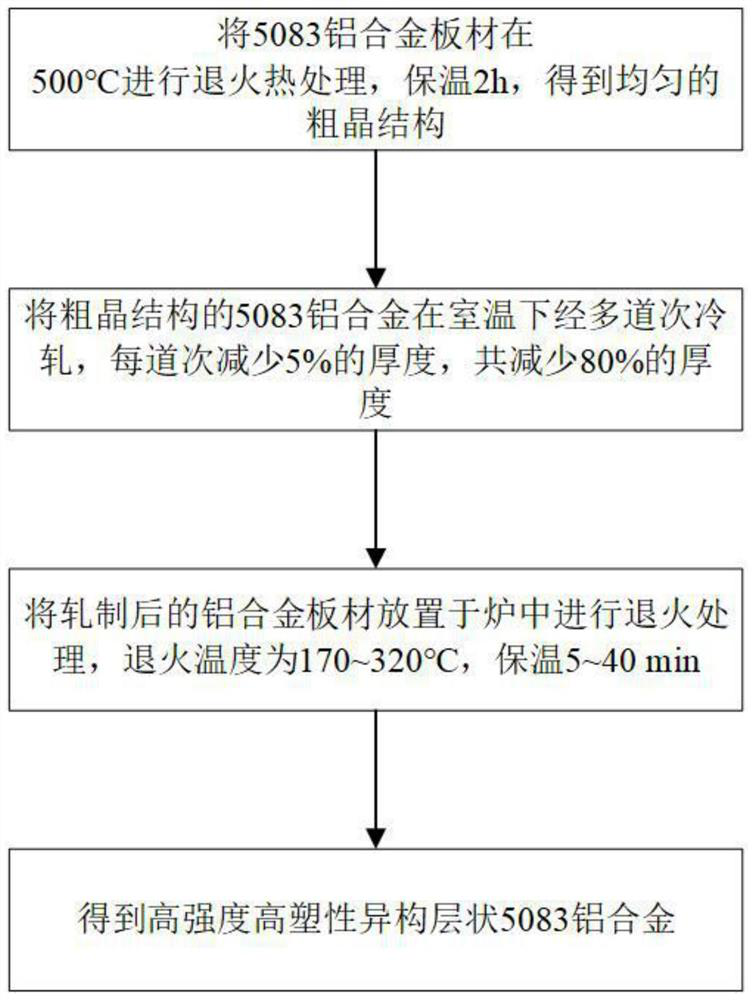

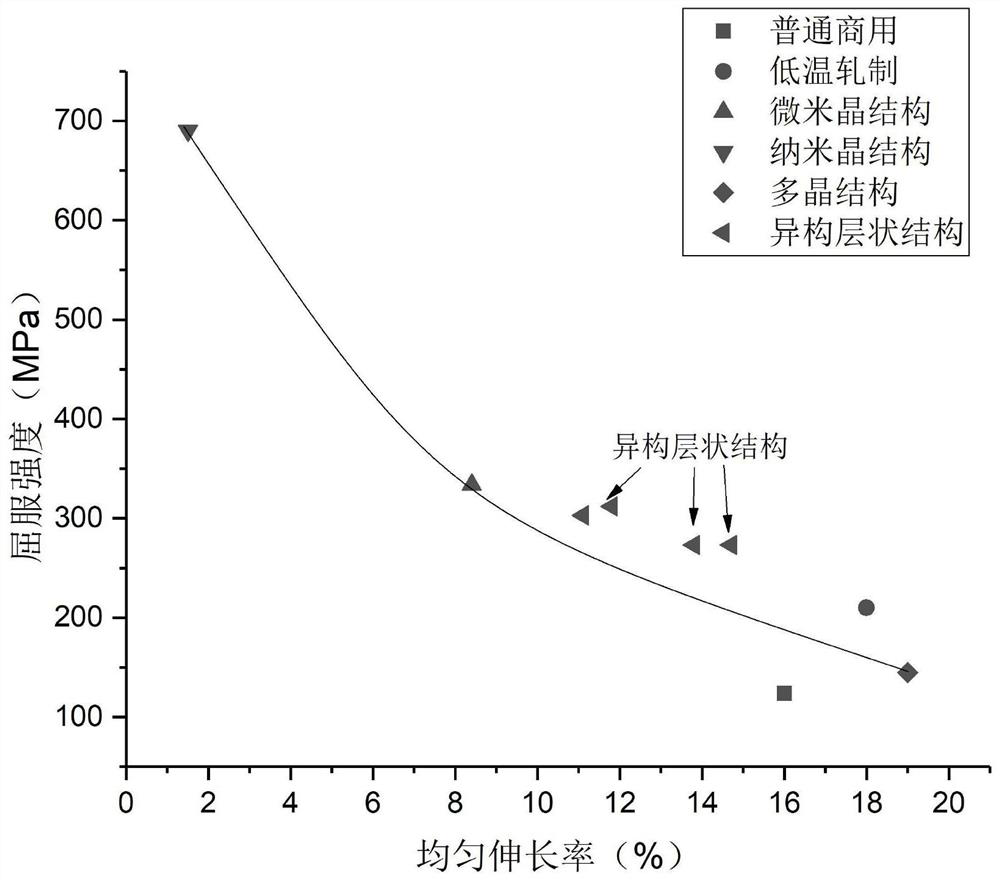

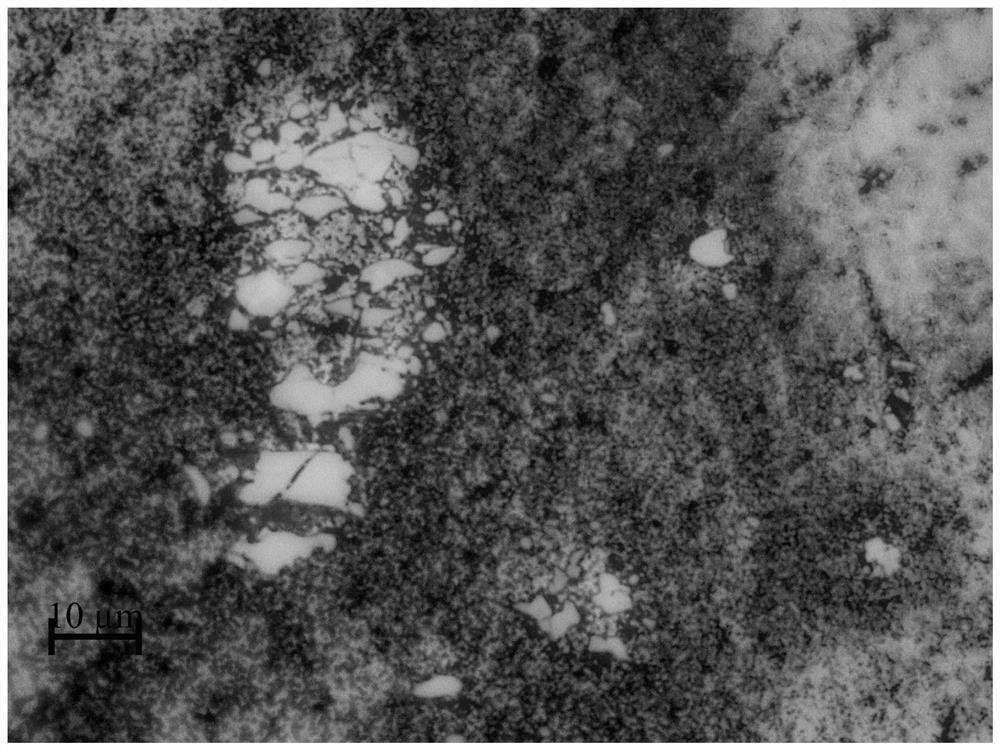

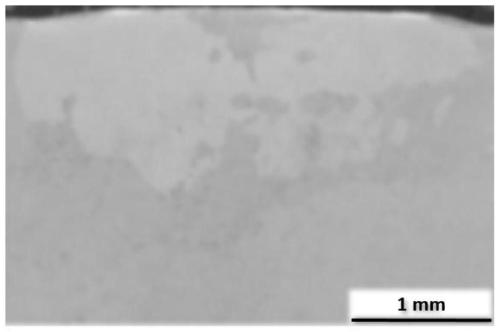

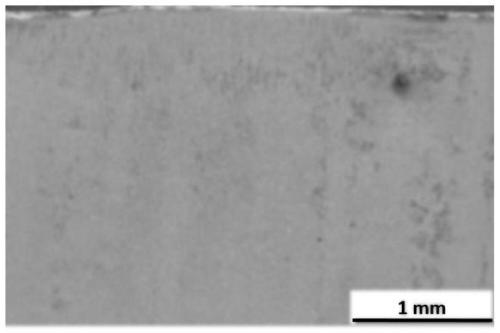

High-strength and high-plasticity heterogeneous layered 5083 aluminum alloy and preparation method thereof

The invention discloses a high-strength and high-plasticity heterogeneous layered 5083 aluminum alloy and a preparation method thereof. The preparation method comprises the steps that a 5083 aluminumalloy plate is placed into a heating furnace and subjected to annealing heat treatment at 500 DEG C, the temperature is kept for 2 h, and a 5083 aluminum alloy plate with a uniform coarse-grain structure is obtained; the 5083 aluminum alloy plate with the uniform coarse-grain structure is subjected to multi-pass cold rolling at room temperature after being discharged from a furnace, the thicknessof the 5083 aluminum alloy plate is reduced by 5% in each pass, and the thickness of the 5083 aluminum alloy plate is totally reduced by 80% finally; and the rolled 5083 aluminum alloy plate is placedinto the furnace for recrystallization annealing treatment, and the heterogeneous layered 5083 aluminum alloy is obtained. According to the preparation method, a rolling method commonly used in industry is adopted, the equipment cost is low, and the rolling reduction of each pass is easy to control; and at the same time, the heat treatment method is simple, the temperature and time of heat treatment are easy to control, and the prepared 5083 aluminum alloy simultaneously has high strength and high plasticity.

Owner:国能锅炉压力容器检验有限公司

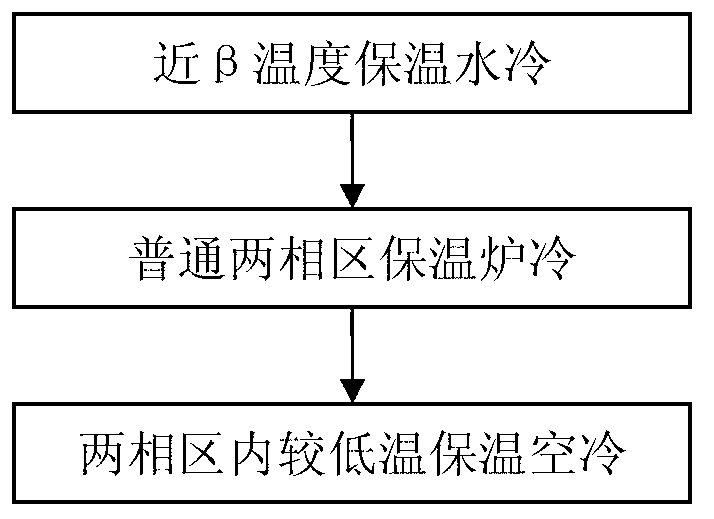

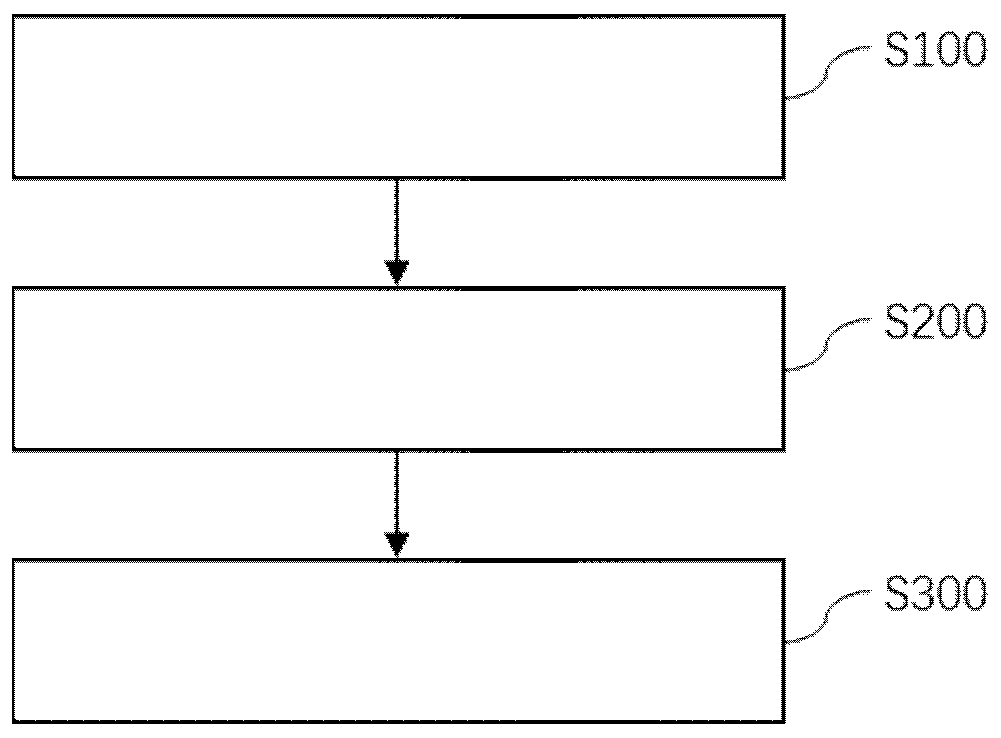

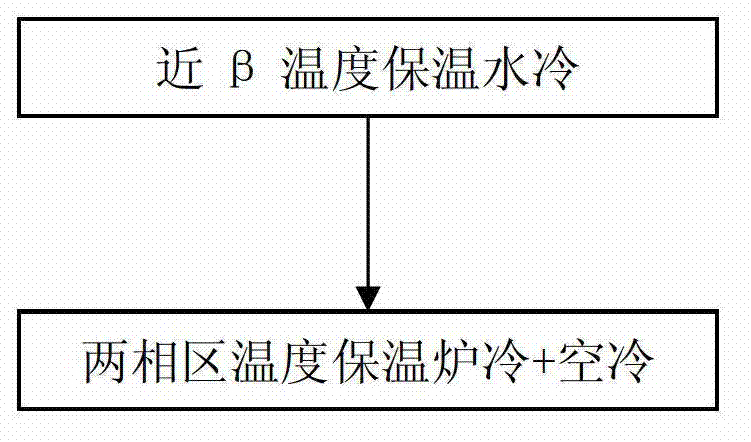

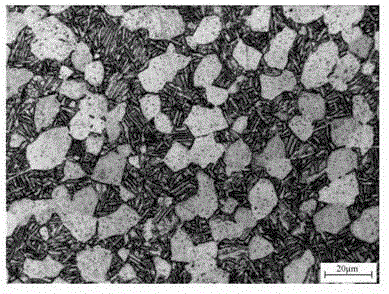

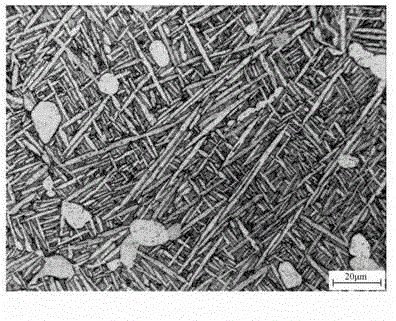

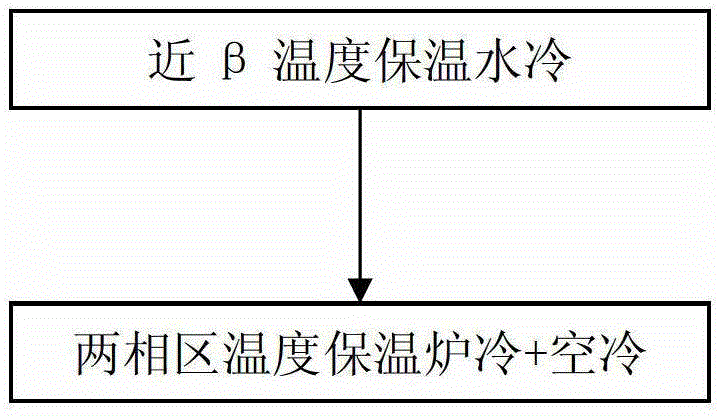

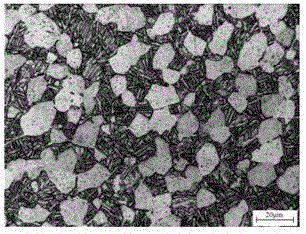

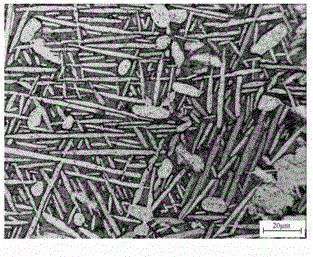

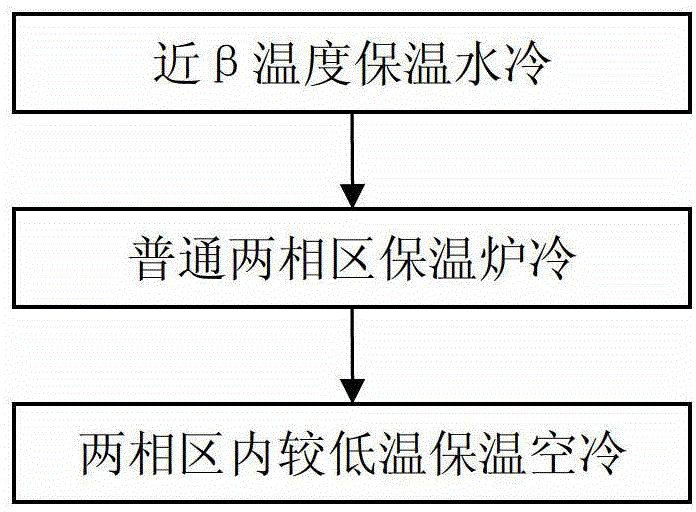

Method for obtaining tri-modal microstructure in dual-phase titanium alloy through furnace cooling

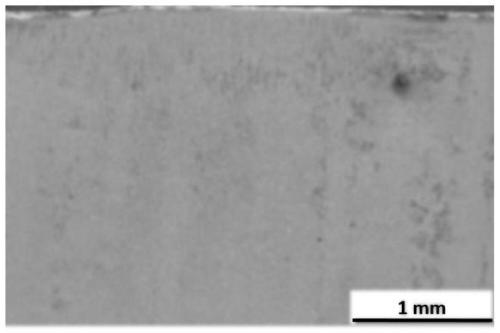

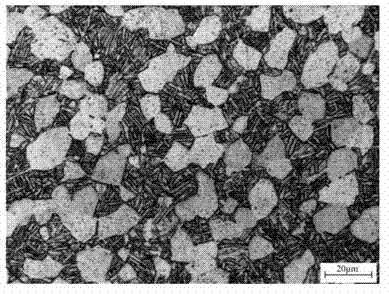

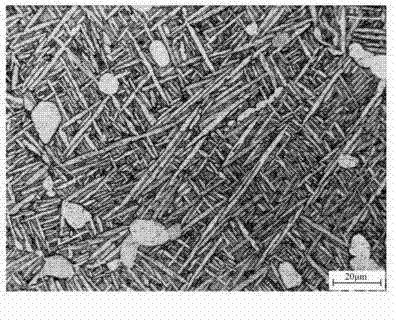

The invention discloses a method for obtaining a tri-modal microstructure in dual-phase titanium alloy through furnace cooling. The method comprises the following steps of: carrying out heat insulation water cooling at near beta temperature; carrying out heat insulation furnace cooling in a common two-phase region and carrying out heat insulation air cooling in a two-phase region at lower temperature. 10-20% of primary equiaxial alpha phases are remained in a titanium alloy microstructure through carrying out heat insulation water cooling at near beta temperature, and the rests are martensites. A test sample microstructure is changed into alpha equal axle, alpha thick silvers and beta residues through carrying out heat insulation furnace cooling in the common two-phase region. The titanium alloy with the tri-modal microstructure is obtained through carrying out heat insulation air cooling in the two-phase region at lower temperature. The method is free of near beta thermal deformation, deformation and nonuniform thermal effect and easy for temperature control, and a dual-modal microstructure can be obtained without carrying out special pretreatment on a primary equiaxial microstructure of the titanium alloy. The method is simple, convenient, feasible and wide in application rang and can be widely used for thermal treatment of titanium alloy parts manufactured by using methods such as rolling, squeezing, machining, forming and the like so as to obtain the tri-modal microstructure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Heat treatment method for inhibiting recrystallization of 3D printed or welded single crystal superalloy

The invention discloses a heat treatment method for inhibiting recrystallization of a 3D printed or welded single crystal superalloy, and belongs to the field of additive manufacturing and metal heattreatment. The method comprises the following steps of removing residual alloy powder and an impurity crystal layer on the surface of the 3D printed or welded single crystal superalloy, performing stress relief annealing on the 3D printed or welded single crystal superalloy to release internal residual stress on the premise of no recrystallization, performing standard heat treatment on the 3D printed or welded single crystal superalloy subjected to stress relief annealing after heat preservation for a necessary period of time at a necessary temperature, so that the strengthening gamma' phase of the 3D printed or welded single crystal superalloy grows to a predetermined size and is orderly arranged. The method can be use for improving the structure and performance of the 3D printed or welded single crystal superalloy, and subsequent heat treatment of the 3D printed or welded single crystal superalloy can be developed based on the method.

Owner:XI AN JIAOTONG UNIV

Method of acquiring tri-modal microstructure in near-alpha titanium alloy through furnace cooling

The invention provides a method of acquiring a tri-modal microstructure in a near-alpha titanium alloy through furnace cooling. According to the method, near-beta temperature heat-insulating water cooling and two-phase region temperature heat-insulating furnace cooling and air cooling are carried out so as to obtain the near-alpha titanium alloy with the tri-modal microstructure; 10 to 20% of an equiaxial primary alpha phase can be retained in a titanium alloy microstructure through the near-beta temperature heat-insulating water cooling, with the balance being martensite; and a tri-modal microstructure titanium alloy consisting of equiaxial alpha, sliver alpha and a beta transformation microstructure is finally formed through the two-phase region temperature heat-insulating furnace cooling and air cooling. The method provided in the invention needs no near-beta thermal deformation and does not generate non-uniform deformation heat effects, temperature can be easily controlled, and special pretreatment does not need to be carried out on the equiaxed-structure near-alpha titanium alloy so as to acquire a duplex microstructure. The thickness value of secondary flake alpha in the invention is in a great adjustable range; the method is simple and easy to implement, has a wide application scope and is applicable to heat treatment of near-alpha titanium alloy parts manufactured by using methods like rolling, extrusion and machining molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Thermal treatment method for improving hardness of TC21 two-phase titanium alloy

The invention discloses a thermal treatment method for improving hardness of a TC21 two-phase titanium alloy and belongs to the technical field of titanium alloy thermal treatment. According to the method, by carrying out heating, heat preservation and water quenching on the TC21 two-phase titanium alloy subjected to beta forging above the phase transformation point, a whole rhombic martensitic structure is obtained, a nanoscale twin crystal alpha-phase structure is obtained by carrying out tempering treatment on the rhombic martensitic structure at 500-550 DEG C, and compared with a forging structure, the hardness of the TC21 titanium alloy is remarkably improved through the nanoscale twin crystal alpha-phase structure. As the TC21 titanium alloy has good hardenability, the whole rhombicmartensitic structure can be easily obtained. The method provided by the invention is small in number of technical parameters, high in feasibility, easy to implement, stable in performance and beneficial for industrial production of TC21.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Thermal treatment method of spheroidal graphite cast iron worm wheel

InactiveCN106636867AImprove wear resistanceSimple heat treatment methodFurnace typesProcess efficiency improvementDuctile ironPearlite

The invention discloses a thermal treatment method of a spheroidal graphite cast iron worm wheel. The spheroidal graphite cast iron worm comprises the following components in percentages by weight: 3.8-4.5% of C, 2.0-2.5% of Si, 0.2-0.4% of Mn, less than 0.08-0.07% of P, less than or equal to 0.02% of S and the balance of Fe. The method comprises the steps: proportioning; preheating; smelting; ladle analysis; final deoxidation; spheroidal graphite treatment and inoculation; pouring; and pearlite treatment. The thermal treatment method is simple. The wear resistance of spheroidal graphite cast iron is improved by virtue of strictly controlling the adding amount of carbon and silicon in the spheroidal graphite cast iron and by means of spheroidizing treatment and pearlite treatment. The method is particularly suitable for casting a worm wheel of a filter cloth-free vacuum filter.

Owner:GUANGXI UNIV

Post-weld heat treatment method for Q345R steel plates for hot roll pressure container barrels

InactiveCN108707740AGuaranteed mechanical propertiesGuaranteed CorrosionFurnace typesHeat treatment furnacesWeld seamMechanical property

The invention discloses a post-weld heat treatment method for Q345R steel plates for hot roll pressure container barrels. The post-weld heat treatment method comprises the processes of steel plate heating, heat preservation and cooling. According to the post-weld heat treatment method, the post-weld heat treatment heating speed, the heat preservation time, the cooling speed and other processes arecontrolled, the good mechanical property of the steel plates is guaranteed, the interior microstructure coarsening and unevenness caused by hot roll of the Q345R (HIC) steel plates for the hot roll pressure container barrels are avoided, the internal defects are eliminated, and the mechanical property and the decay resistance of the steel plates and the welding heat effect zones are guaranteed. The treated steel plates are well matched with the 1 / 2 position of welding seams in the plate thickness direction in obdurability, the surface hardness is low, the mechanical property of the steel plates is stable, sulfuretted hydrogen corrosion resistance is good, and the post-weld heat treatment method is suitable for post-weld heat treatment production and checking of same-like steel plates withthe thicknesses ranging from 110 mm to 160 mm. The heat treatment method is simple and practical, and is suitable for volume production in plants.

Owner:WUYANG IRON & STEEL

Heat treatment method of non-ferrous metal hot roll

ActiveCN107447096ASimple heat treatment methodHigh strengthFurnace typesHeat treatment furnacesEconomic benefitsHigh intensity

The invention discloses a heat treatment method of a non-ferrous metal hot roll, and relates to the technical field of metal processing. The method comprises the following steps: 1) preheating: the roll is placed in a high-temperature furnace for preheating treatment after being demolded and cleaned; 2) secondary normalization; 3) quenching: double-frequency induction quenching is performed on the working surface of the roll, and the cooling mode is a combination of oil cooling and air cooling; 4) tempering; 5) annealing. The heat treatment method of the non-ferrous metal hot roll is simple and feasible; the treated non-ferrous metal hot roll is high in strength and good in thermal cracking resistance and electrochemical corrosion resistance, and has excellent accident resistance, fatigue resistance and abrasion resistance, thereby meeting operating requirements of practical production and application; the service life of the non-ferrous metal hot roll is effectively prolonged, and production efficiency and economic benefits are increased.

Owner:安徽昕悦铸造科技有限公司

Aluminum alloy heat treatment process

The invention discloses an aluminum alloy heat treatment process. The aluminum alloy heat treatment process comprises the following steps that (1) quenching is conducted, specifically, after aluminum alloy sectional material products are extruded from an outlet, all quenching fans are immediately started to conduct cooling, and the temperature of the sectional material outlet is controlled between 520 DEG C and 550 DEG C; (2) artificial aging is conducted, specifically, the quenched aluminum alloy sectional materials are heated in an aging furnace to 190 DEG C-200 DEG C, and then heat preservation is conducted for 2 hours; (3) inspection is conducted, specifically, the aluminum alloy sectional materials obtained after artificial aging are inspected; (4) second-time aging is conducted, specifically, the unqualified products obtained after first-time aging are subjected to second-time aging, the temperature of second-time aging is 160 DEG C- 170 DEG C, and heat preservation is conducted for 10 hours; (5) the unqualified products obtained after second-time aging are heated to the temperature of 250 DEG C-300 DEG C, heat preservation is conducted for 3-5 min, and the temperature of the unqualified products is quickly decreased to the room temperature; and (6) double-stage aging is conducted. According to the aluminum alloy heat treatment method provided by the invention, the comprehensive mechanical property of aluminum alloy is improved, the operation procedure is simple, meanwhile, multiple heat treatment reworking of the unqualified products is realized, and loss is reduced.

Owner:ANHUI LANT ALUMINUM

Thermal treatment method for improving mechanical property of titanium alloy strip

The invention discloses a thermal treatment method for improving mechanical property of a titanium alloy strip, which comprises the following steps of: 1, a first stage of thermal treatment: performing the first stage of thermal treatment on the treated titanium alloy strip by adopting a vacuum thermal treatment furnace, wherein the heating temperature is 780 to 820 DEG C, the heat preservation time is 10 to 20 minutes and the cooling mode is vacuum gas quenching; and a second stage of thermal treatment: performing the second stage of thermal treatment on the treated titanium alloy strip after the first stage of thermal treatment by adopting the vacuum thermal treatment furnace, wherein the heating temperature is 460 to 540 DEG C, the heat preservation time is 6 to 10 hours and the cooling mode is vacuum furnace cooling. The method has the advantages of reasonable design, simple thermal treatment, simple and convenient operation and good thermal treatment effect; the mechanical property of the treated titanium alloy strip is greatly improved; and the method fully meets the technical requirements of the TB2 titanium alloy strip for aviation and spaceflight for high strength, high toughness, high modulus and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A heat treatment method for non-ferrous metal hot roll

ActiveCN107447096BSimple heat treatment methodHigh strengthFurnace typesHeat treatment furnacesElectrochemical corrosionQuenching

The invention discloses a heat treatment method of a non-ferrous metal hot roll, and relates to the technical field of metal processing. The method comprises the following steps: 1) preheating: the roll is placed in a high-temperature furnace for preheating treatment after being demolded and cleaned; 2) secondary normalization; 3) quenching: double-frequency induction quenching is performed on the working surface of the roll, and the cooling mode is a combination of oil cooling and air cooling; 4) tempering; 5) annealing. The heat treatment method of the non-ferrous metal hot roll is simple and feasible; the treated non-ferrous metal hot roll is high in strength and good in thermal cracking resistance and electrochemical corrosion resistance, and has excellent accident resistance, fatigue resistance and abrasion resistance, thereby meeting operating requirements of practical production and application; the service life of the non-ferrous metal hot roll is effectively prolonged, and production efficiency and economic benefits are increased.

Owner:安徽昕悦铸造科技有限公司

Method for acquiring tri-modal microstructure in near-alpha titanium alloy

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Platinum film with oversized crystal grains and preparation method thereof

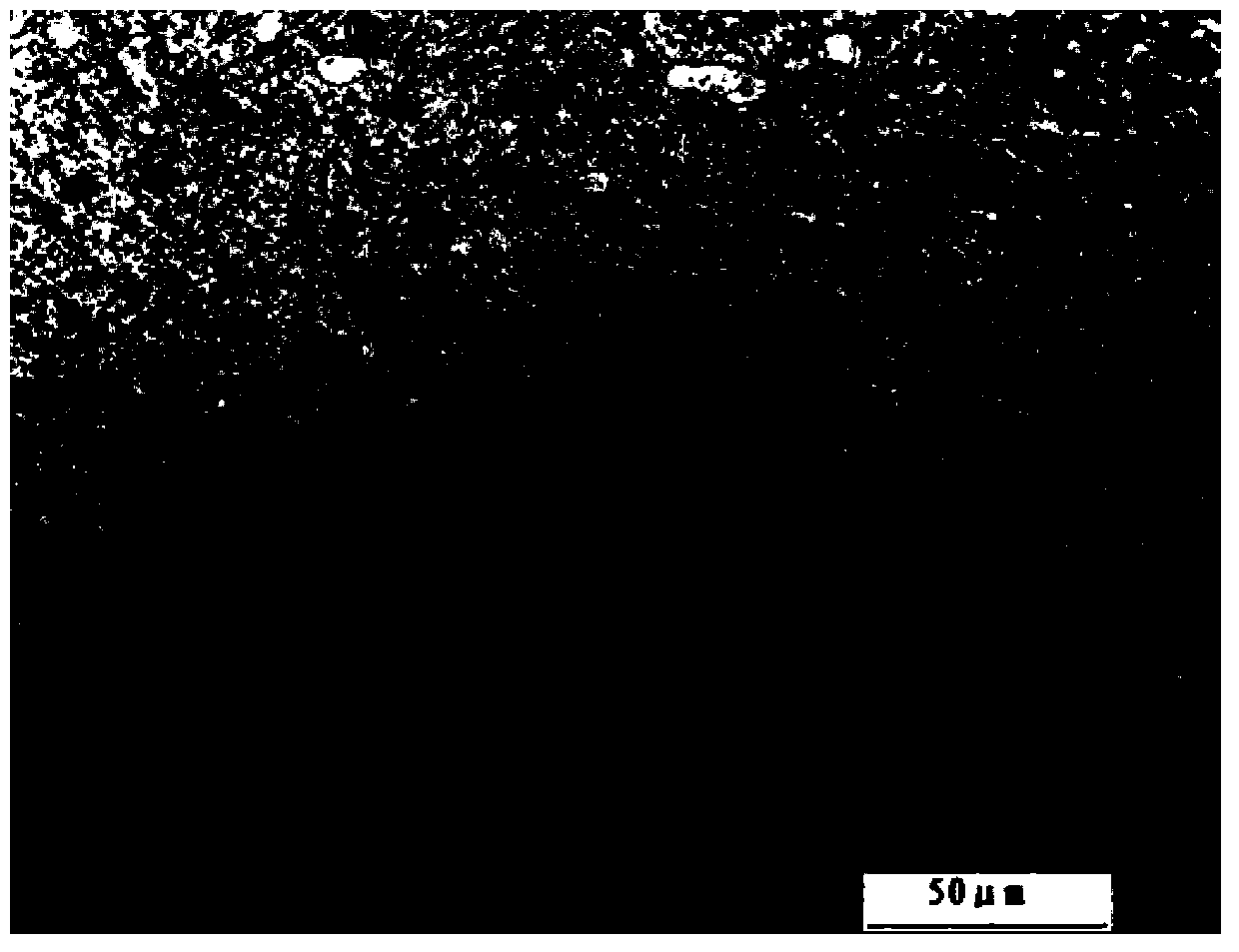

PendingCN114752892ARefine the grain sizeLess structural defectsVacuum evaporation coatingSputtering coatingMixed gasMaterials science

The invention relates to the technical field of thin films, in particular to a platinum thin film with ultra-large crystal grains and a preparation method of the platinum thin film. A conventional magnetron sputtering method is used for preparing the platinum thin film, mixed gas of argon and oxygen is used as sputtering carrier gas, the oxygen content in the deposited platinum thin film is adjusted by adjusting the oxygen content in the mixed gas of argon and oxygen during sputtering, and the oxygen content in the deposited platinum thin film is adjusted in cooperation with the subsequent heat treatment temperature and heat treatment atmosphere of the thin film. The surface energy and strain energy in the growth process of thin film crystal grains are mainly adjusted, so that the crystal grains with specific orientation have thermodynamic or dynamic growth advantages in a certain stage of heat treatment, surrounding small crystal grains are continuously consumed and grow abnormally until the abnormally grown crystal grains are in contact with one another, and the growth efficiency of the thin film is improved. And finally, the platinum film with large grain size and uniform grain distribution is obtained. The preparation method disclosed by the invention is simple, and the prepared platinum film has few structural defects and excellent electrical properties.

Owner:江苏精瓷智能传感技术研究院有限公司

Method for obtaining tri-state tissue from titanium alloy

ActiveCN102758161BNo deformation temperature rise effectEasy temperature controlTest sampleThermal deformation

The invention discloses a method for obtaining a tri-state tissue from a titanium alloy, and is characterized in that through thermal treatment at near beta temperature, a test sample tissue is changed to an alpha isometric+martensite; through temperature solution in a two-phase region, the test sample tissue is changed to an alpha isometric+alpha silver+martensite; and the titanium alloy with the tri-state tissue is obtained through annealing. According to the invention, near beta thermal deformation is not required, a deformation temperature rise effect cannot be generated, the temperature is easy to control, and an initial isometric tissue of the titanium alloy can become a duplex tissue without special pretreatment. The method, provided by the invention, is simple and easy, and wide in application range, and can be applied to thermal treatment of titanium alloy parts, which are produced by methods, such as rolling, extrusion, machining and the like, so that the tri-state tissue is obtained. In particular for complicated titanium components, locally complicated components or large components, after a near clean form of the components is obtained through machining, the tri-state tissue is obtained through the method provided by the invention.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Heat treatment methods to suppress recrystallization of 3D printed or welded single crystal superalloys

The invention discloses a heat treatment method for inhibiting recrystallization of a 3D printed or welded single crystal superalloy, and belongs to the field of additive manufacturing and metal heattreatment. The method comprises the following steps of removing residual alloy powder and an impurity crystal layer on the surface of the 3D printed or welded single crystal superalloy, performing stress relief annealing on the 3D printed or welded single crystal superalloy to release internal residual stress on the premise of no recrystallization, performing standard heat treatment on the 3D printed or welded single crystal superalloy subjected to stress relief annealing after heat preservation for a necessary period of time at a necessary temperature, so that the strengthening gamma' phase of the 3D printed or welded single crystal superalloy grows to a predetermined size and is orderly arranged. The method can be use for improving the structure and performance of the 3D printed or welded single crystal superalloy, and subsequent heat treatment of the 3D printed or welded single crystal superalloy can be developed based on the method.

Owner:XI AN JIAOTONG UNIV

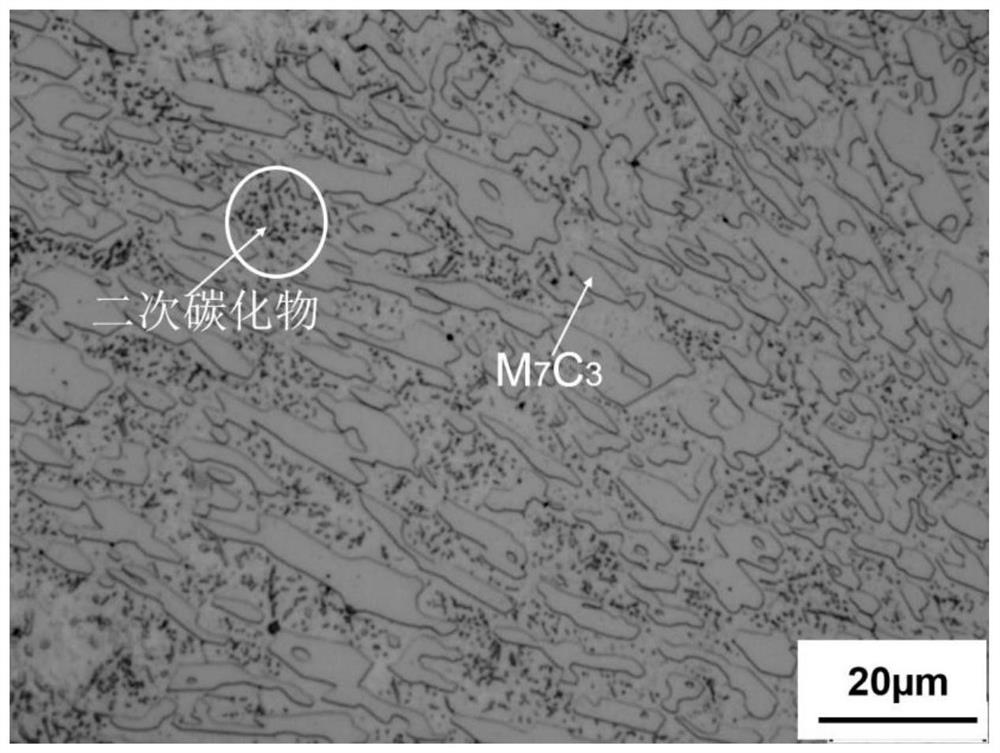

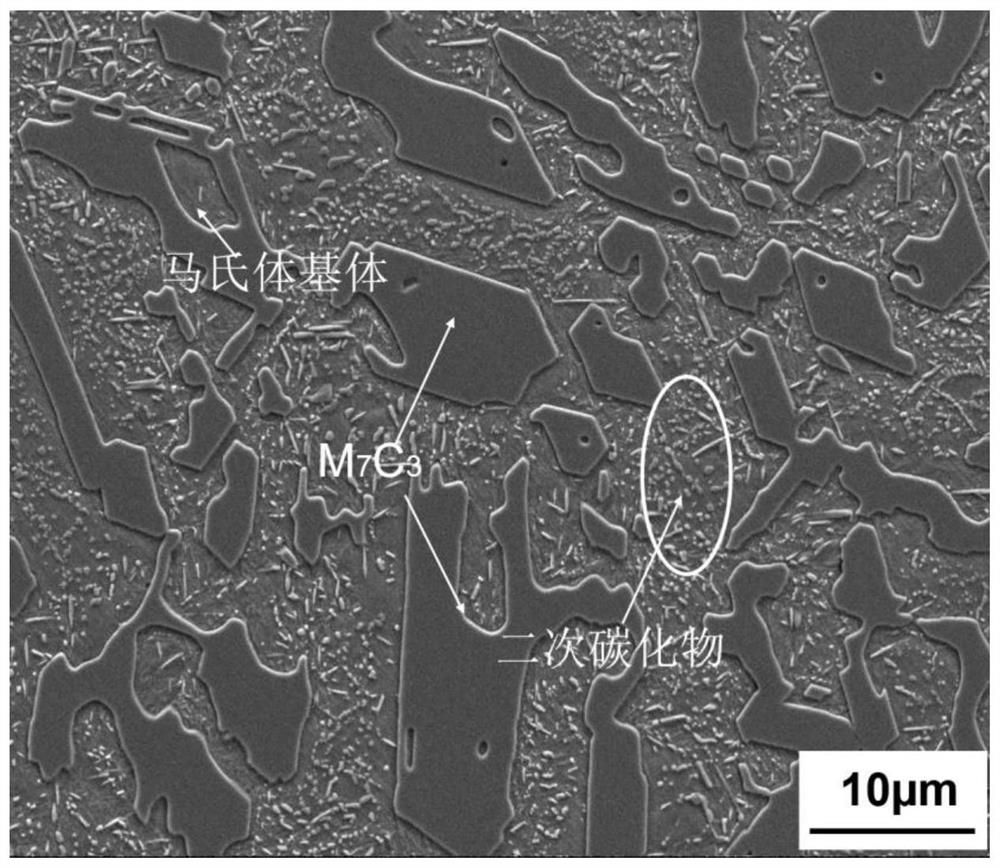

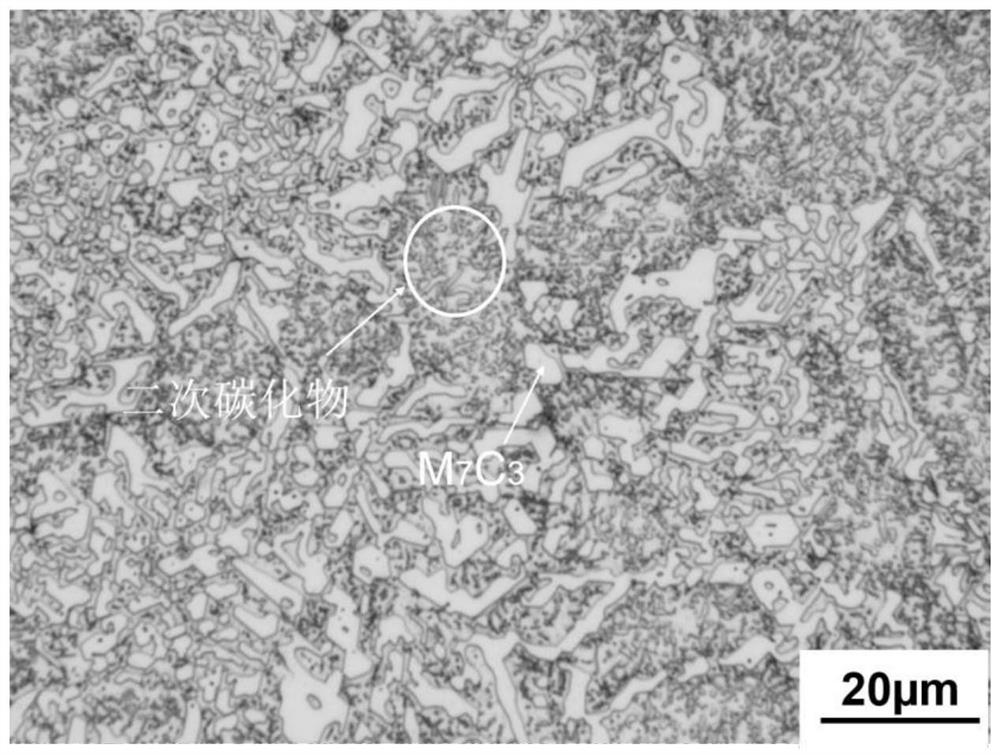

High-chromium martensite cast iron heat treatment method based on natural aging

The invention relates to a high-chromium martensite cast iron heat treatment method based on natural aging. According to the technical scheme, high-chromium martensite cast iron comprises the following chemical components in percentage by mass: 2.5-3.0% of C, 18-22% of Cr, 0.5-0.9% of Si, 2.0-2.5% of Mn, 0.7-1.2% of Cu, less than or equal to 0.049% of P, less than or equal to 0.049% of S, and thebalance of Fe, wherein 6.5 <=Cr / C<=7.3. The preparation method comprises the following steps: proportioning the chemical components, performing smelting, pouring and polishing, keeping the temperatureat 900-1000 DEG C for 1-2 hours after polishing, then carrying out water quenching until room temperature is reached, and performing natural aging at room temperature for 7-21 days to prepare the high-chromium martensite cast iron. The hardness of the high-chromium martensite cast iron ranges from 65.5 HRC to 67.5 HRC, the V notch impact work ranges from 2.4 J to 5.2 J, and the matrix structure is martensite. The method has the advantages of simple heat treatment process, low heat treatment cost and energy conservation, and the high-chromium martensite cast iron prepared after natural aging is high in hardness and good in toughness.

Owner:WUHAN UNIV OF SCI & TECH +1

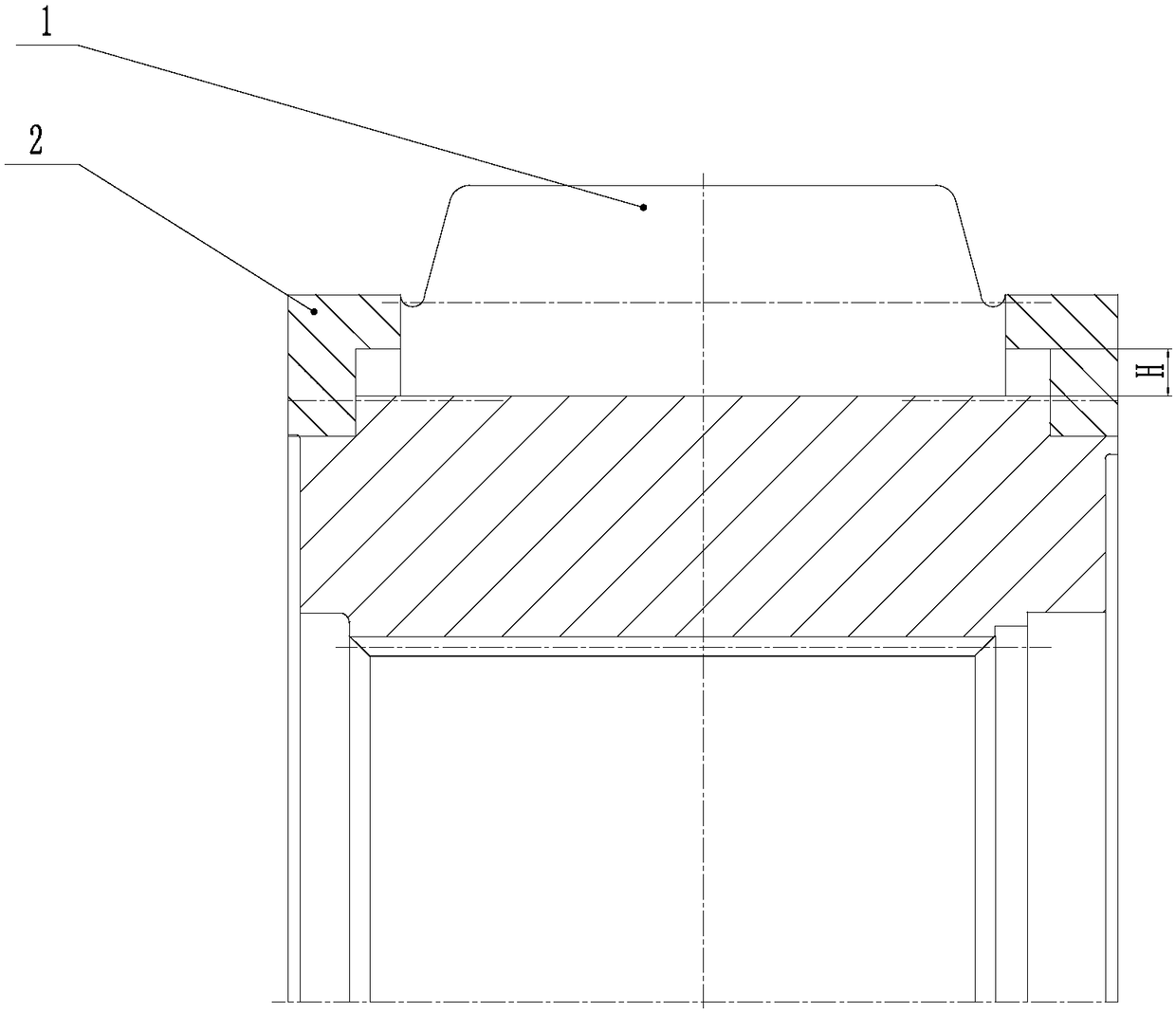

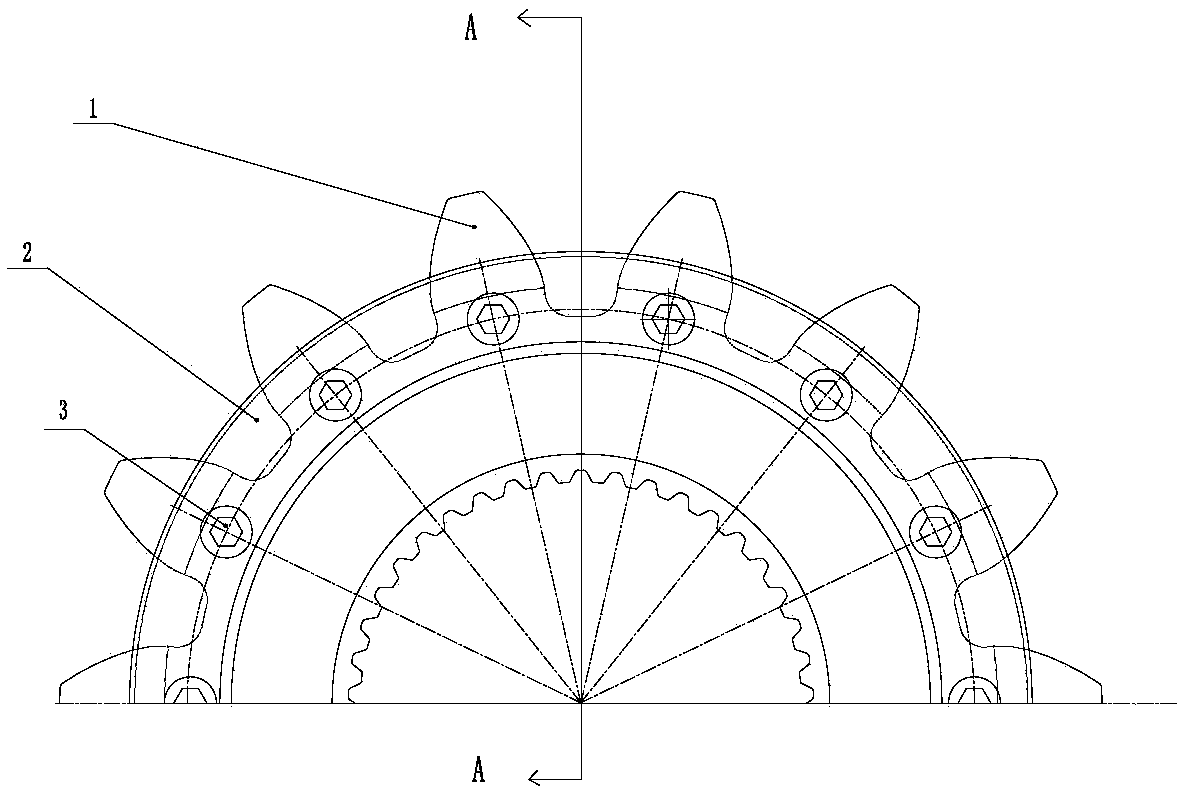

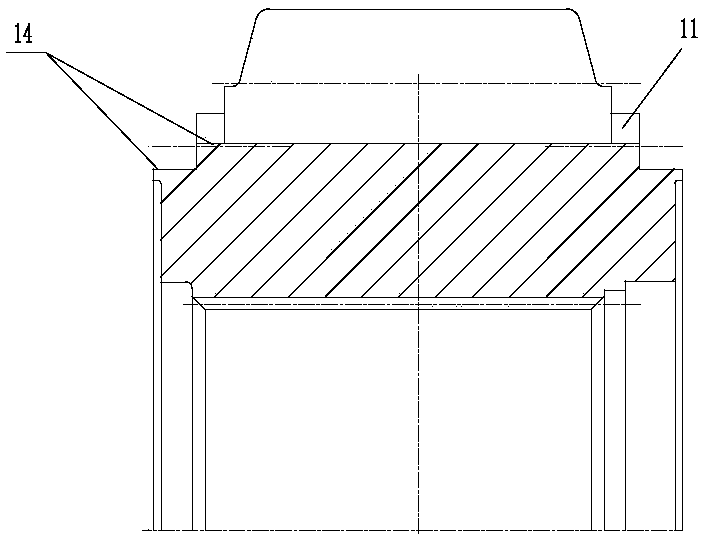

Push and press gear

PendingCN108386517AImprove processing efficiencySimple heat treatment methodPortable liftingGearing elementsFlange

The invention discloses a push and press gear. The push and press gear comprises a gear, main flanges and bolts, and flange inner holes are two layers of stepped holes which comprise spline holes fromlarge to small and supported holes. A plurality of key teeth protruding into the spline holes are uniformly distributed in the circumferences of the spline holes, key slots are formed between the keyteeth, and countersunk screw holes are separately formed in the positions which supported hole walls correspond to the multiple key slots. Ladder steps and corresponding key teeth I which correspondto the two layers of stepped holes of the flange inner holes are arranged on the side walls of the two axial end surfaces of the gear, and screw holes corresponding to the countersunk screw holes areformed in the key teeth I. Flange flanges are separately installed at the two ends of the gear, the ladder steps of the two layers of stepped holes are inlaid, the key teeth are inlaid into tooth grooves at the root of the gear, and the key slots and the key teeth are inlaid. The flange flanges are connected with splines of the gear and are fixed by the bolts passing through the countersunk screwholes and the screws. According to the push and press gear, the machining efficiency and quality are improved, a heat treatment method is simplified, and 20-40% cost can be saved.

Owner:BEIJING DASHENG GEER METALLURGICAL EQUIP CO LTD

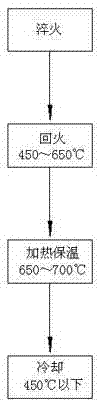

35crmnsi steel heat treatment method to eliminate the second type of temper brittleness and improve toughness and 35crmnsi steel

The invention relates to the technical field of heat treatment of castings and forgings, in particular to 35CrMnSi steel, and a heat treatment method for eliminating second-class temper brittleness and improving toughness of the 35CrMnSi steel, which is suitable for quenching and tempering. The heat treatment method comprises a series of steps of quenching, tempering, heating, preserving heat and cooling, and integrates physical and chemical treatment technologies and the like, so that insufficient and incomplete basic structural transformation of the 35CrMnSi steel is avoided, the second-class temper brittleness is eliminated, and the toughness of a product is improved; the heat treatment method has the advantages as follows: by the heat treatment method, the quality of the product can be improved, the defective rate can be reduced, production resources can be saved, the production cost of an enterprise can be reduced, the second-class temper brittleness of the 35CrMnSi steel can be eliminated and the toughness of the 35CrMnSi steel can be improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

A heat treatment method for additively manufacturing single crystal nickel-based superalloys

ActiveCN109014215BImprove organizationImprove performanceAdditive manufacturing apparatusHeat-affected zoneCrystal orientation

The invention relates to a heat treatment method for additive manufacturing monocrystal nickel-base superalloy. The heat treatment method includes the steps that to-be-processed additive manufacturingmonocrystal nickel-base superalloy is subjected to solid solution heat treatment, aging heat treatment and cooling in a heat treatment furnace, slicing and sample preparation are carried out on the processed additive manufacturing monocrystal nickel-base superalloy, combined with microstructure characterization and crystal orientation analysis, and the effect of the heat treatment method is judged according to the size of gamma<'> phase and whether recrystallization occurs in a heat-affected zone and a epitaxial growth zone or not. According to the heat treatment method for the additive manufacturing monocrystal nickel-base superalloy, the gamma<'> phase is dissolved, re-precipitated, and grown up in the subsequent aging process by applying appropriate heat energy to the additive manufacturing monocrystal nickel-base superalloy, thus the gamma<'> phase with uniform size distribution and regular shape is obtained, and the purposes of microstructure improvement and alloy property optimization are achieved.

Owner:XI AN JIAOTONG UNIV +1

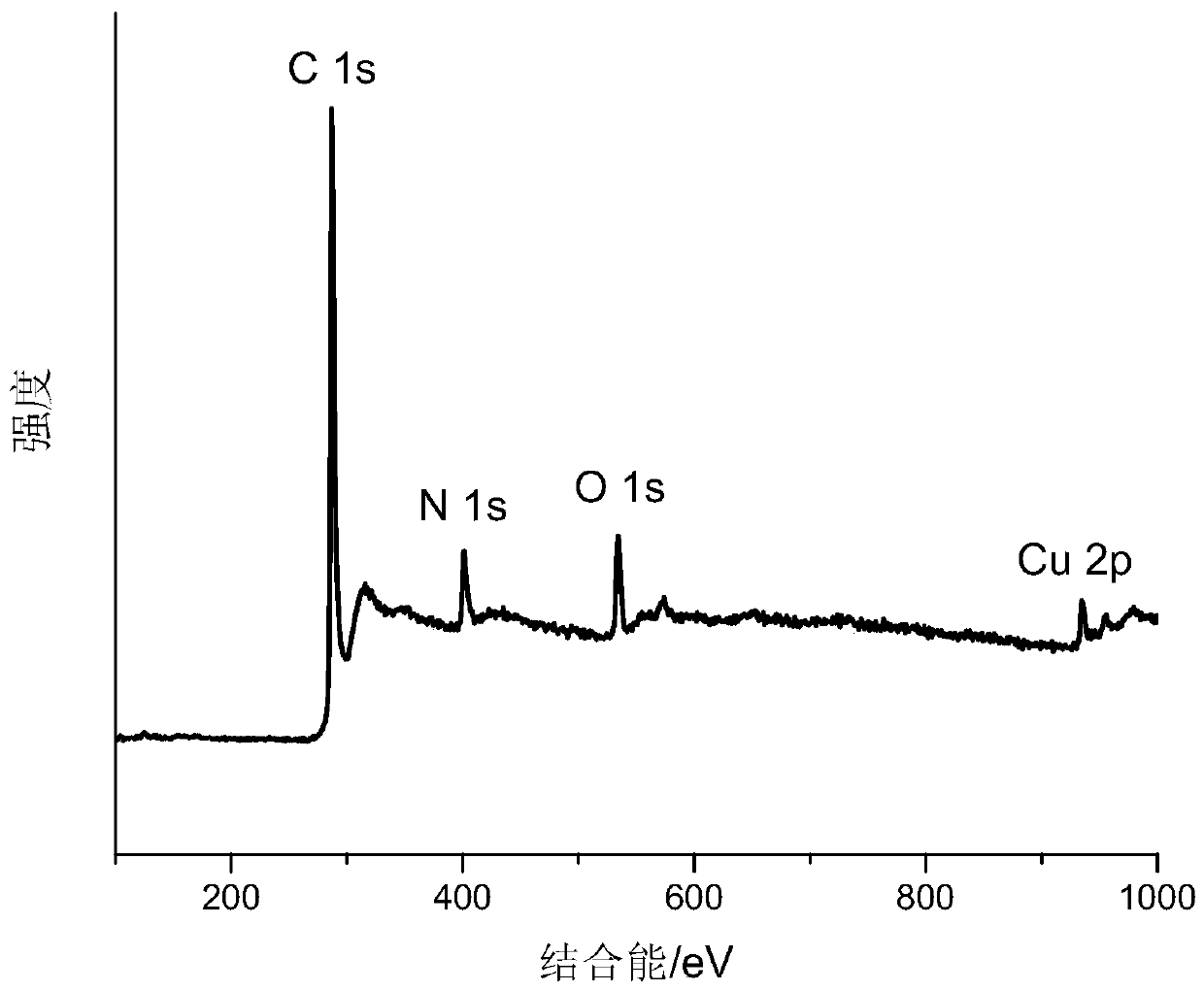

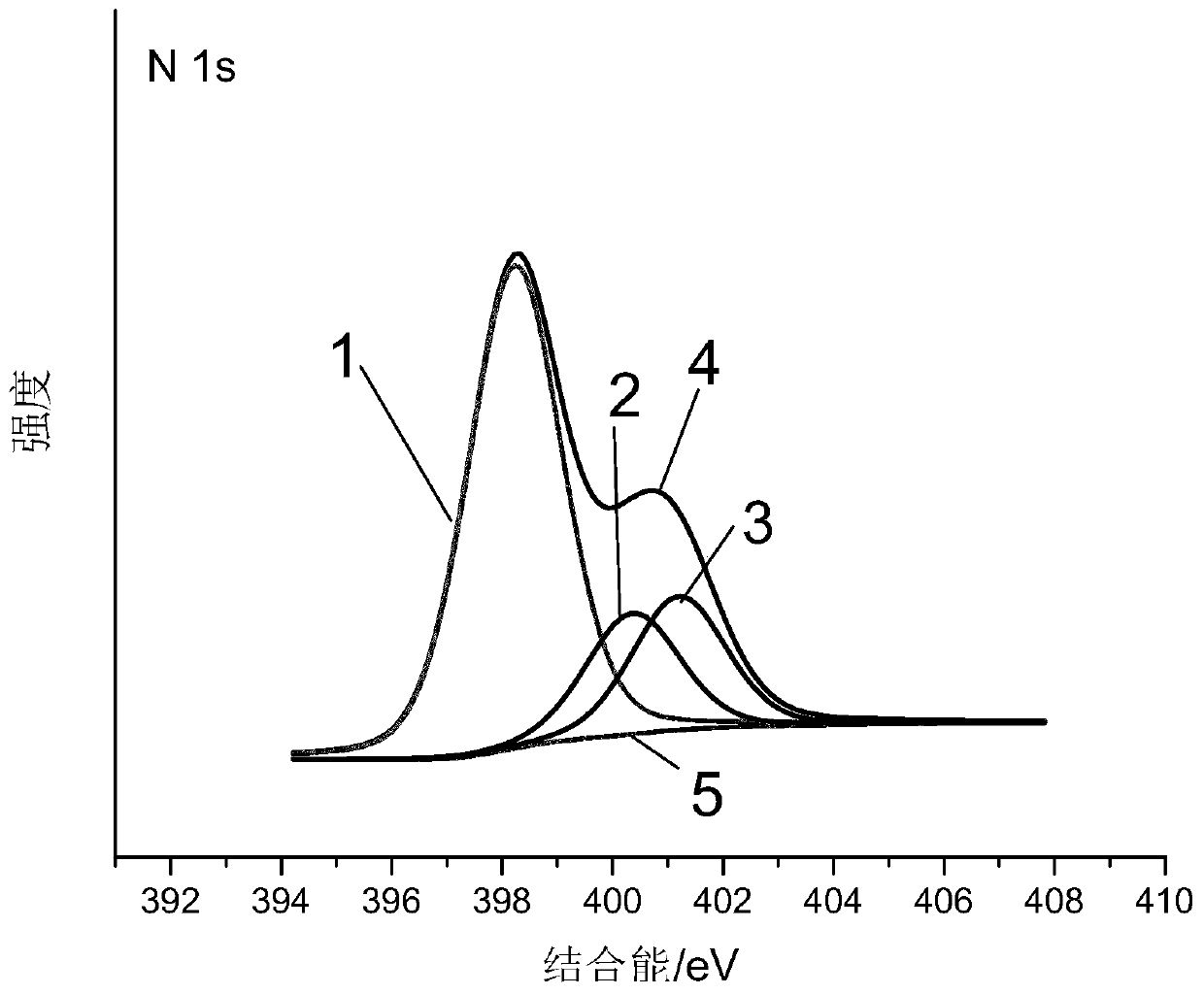

A sp doped with monodisperse metal atoms 2 Preparation method of hybrid carbon material

The invention discloses an sp2 hybrid carbon material doped with single dispersed metal atom and a preparation method of the sp2 hybrid carbon material, and relates to an sp2 hybrid carbon material and the preparation method thereof. The invention aims to solve the problems of high preparation cost of metal doped carbon material and uncontrollable metal introduction site. According to the sp2 hybrid carbon material doped with the single dispersed metal atom, a part of metal element is bonded with N atom evenly through a coordinate bond and doped in a sp2 hybrid carbon framework, and the other part is evenly distributed in the sp2 hybrid carbon material doped by the single dispersed metal atom. The preparation method includes steps of firstly, mixing and acquiring a nitrogen source / carbon source fluid mixture; secondly, freeze-drying and acquiring a nitrogen source / carbon source solid mixture; thirdly, sintering to obtain the sp2 hybrid carbon material doped with the single dispersed metal atom. The invention is mainly used for preparing the sp2 hybrid carbon material doped with the single dispersed metal atom.

Owner:HARBIN INST OF TECH

Method of acquiring tri-modal microstructure in near-alpha titanium alloy through furnace cooling

The invention provides a method of acquiring a tri-modal microstructure in a near-alpha titanium alloy through furnace cooling. According to the method, near-beta temperature heat-insulating water cooling and two-phase region temperature heat-insulating furnace cooling and air cooling are carried out so as to obtain the near-alpha titanium alloy with the tri-modal microstructure; 10 to 20% of an equiaxial primary alpha phase can be retained in a titanium alloy microstructure through the near-beta temperature heat-insulating water cooling, with the balance being martensite; and a tri-modal microstructure titanium alloy consisting of equiaxial alpha, sliver alpha and a beta transformation microstructure is finally formed through the two-phase region temperature heat-insulating furnace cooling and air cooling. The method provided in the invention needs no near-beta thermal deformation and does not generate non-uniform deformation heat effects, temperature can be easily controlled, and special pretreatment does not need to be carried out on the equiaxed-structure near-alpha titanium alloy so as to acquire a duplex microstructure. The thickness value of secondary flake alpha in the invention is in a great adjustable range; the method is simple and easy to implement, has a wide application scope and is applicable to heat treatment of near-alpha titanium alloy parts manufactured by using methods like rolling, extrusion and machining molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for obtaining tri-modal microstructure in dual-phase titanium alloy through furnace cooling

The invention discloses a method for obtaining a tri-modal microstructure in dual-phase titanium alloy through furnace cooling. The method comprises the following steps of: carrying out heat insulation water cooling at near beta temperature; carrying out heat insulation furnace cooling in a common two-phase region and carrying out heat insulation air cooling in a two-phase region at lower temperature. 10-20% of primary equiaxial alpha phases are remained in a titanium alloy microstructure through carrying out heat insulation water cooling at near beta temperature, and the rests are martensites. A test sample microstructure is changed into alpha equal axle, alpha thick silvers and beta residues through carrying out heat insulation furnace cooling in the common two-phase region. The titanium alloy with the tri-modal microstructure is obtained through carrying out heat insulation air cooling in the two-phase region at lower temperature. The method is free of near beta thermal deformation, deformation and nonuniform thermal effect and easy for temperature control, and a dual-modal microstructure can be obtained without carrying out special pretreatment on a primary equiaxial microstructure of the titanium alloy. The method is simple, convenient, feasible and wide in application rang and can be widely used for thermal treatment of titanium alloy parts manufactured by using methods such as rolling, squeezing, machining, forming and the like so as to obtain the tri-modal microstructure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

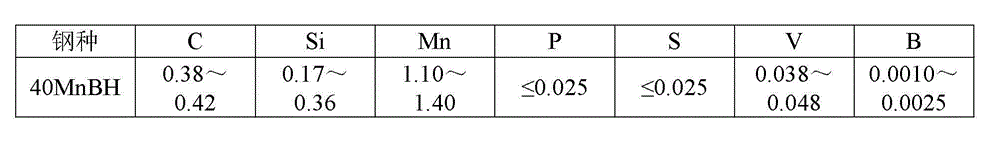

Method for improving hardenability of 40MnBH steel for hardenability maintenance structure

The invention relates to a method for improving hardenability of 40MnBH steel for a hardenability maintenance structure and is characterized in that ferrovanadium is added to achieve microalloying of vanadium on the basis of chemical components of 40MnBH steel prescribed by GB / T5216-2004 standards during smelting, so that final 40MnBH steel comprises, by weight, 0.38% to 0.42% of carbon, 0.17% to 0.35% of silicon, 1.10% to 1.35% of manganese, less than or equal to 0.025% of phosphorus, less than or equal to0.025% of sulfur, 0.0010% to 0.0025% of boron, 0.038% to 0.048% of vanadium, and the balance ferrum and inevitable impurities. The method has the advantages that the kind of added microalloy elements is small; the adding method during smelting is simple, and the microalloy elements can be added with other alloy elements; addition amounts of microalloy elements are small, the cost is low, and the vanadium accounts for 0.038% to 0.048%; special technical processes are not needed during smelting and rolling, the comprehensive effectiveness is enhanced, and the effect of improving the hardenability is obvious; and the heat treatment method is simple when users use the 40MnBH hot-rolled steel, the heating temperature is not needed to be increased deliberately, the comprehensive performance of produced motor shaft products is good, machining properties are good, and the machining amount is small.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

A kind of metal superhydrophobic surface and preparation method thereof

The invention relates to a metal super-hydrophobic surface and a preparation method thereof. The preparation method comprises following two steps: firstly, electroplating method is adopted, traditional Watts electroplate liquid is taken as a base electroplate liquid, conductive metal base materials such as stainless steel, copper, aluminium alloy, and magnesium aluminum alloy, are taken as a negative electrode, and copper sheets are taken as a positive electrode so as to prepare a nickel coating layer; and secondly, an obtained electroplated surface and an ethanol solution containing fluorosilane are delivered into a heating furnace for heat treatment, and an obtained sample is subjected to washing and blow drying so as to obtain the surface with super-hydrophobicity on metal workpieces. The preparation method of the metal super-hydrophobic surface is simple; cost is low; and the preparation method is convenient for industrialized application. Contact angle of the obtained metal super-hydrophobic surface is more than 155 DEG, and rolling angel is less than 10 DEG; the metal super-hydrophobic surface possesses excellent super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance; the preparation method is suitable for obtaining the metal super-hydrophobic surfaces with super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance on the surfaces of a plurality of metal base materials with complex shapes and large area.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com