Thermal treatment method for improving hardness of TC21 two-phase titanium alloy

A heat treatment method, TC21 technology, applied in the field of titanium alloy heat treatment, can solve the problems of difficult deformation, high energy consumption, low efficiency, etc., and achieve the effect of stable performance, less process parameters and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the specific steps of this embodiment are as follows:

[0017] (1) Process the TC21 titanium alloy bar after β forging into a titanium alloy sample with a size of 60×60×120 mm.

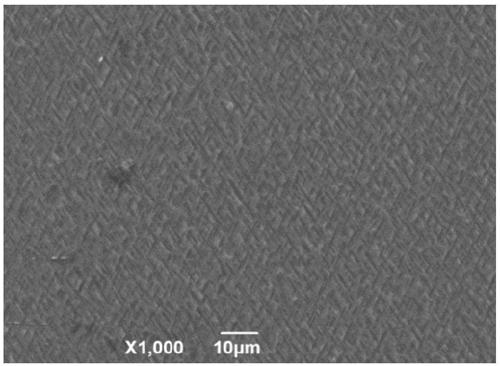

[0018] (2) After heating the heat treatment furnace to 1050°C, place the titanium alloy sample, keep it warm for 4 hours, and then quench it in water at a water temperature of 10°C to obtain a quenched sample whose structure is all rhomboid martensite. A block sample of 20×20×10 was cut from the quenched sample, and after the sample was ground, polished and corroded, the martensite structure observed by scanning electron microscope (SEM) was as follows: figure 1 shown.

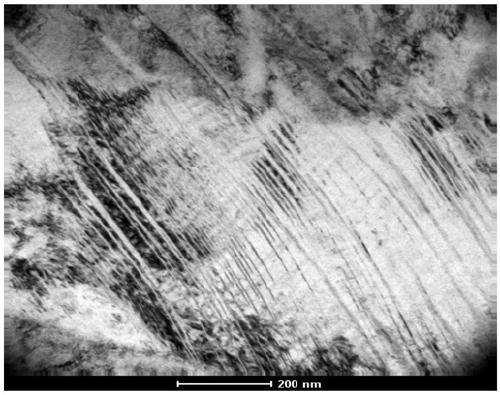

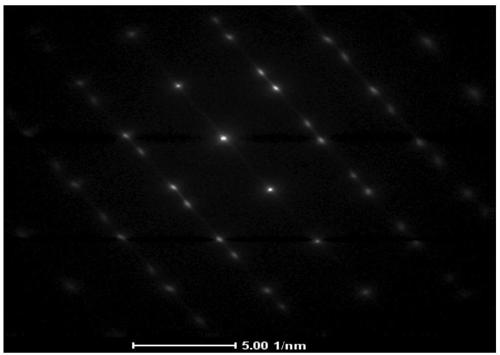

[0019] (3) Heat the heat treatment furnace to 500 ° C, then put the quenched sample obtained in step (1) into the heating furnace, keep it warm for 4 hours, and then air-cool to obtain the aging treatment sample, whose structure is nano-twin α phase and β phase . Cut 20 × 20 × 10 block samples from the aging tr...

Embodiment 2

[0023] Embodiment 2: the specific steps of this embodiment are as follows:

[0024] (1) Process the TC21 titanium alloy bar after β forging into a titanium alloy sample with a size of 60×60×120 mm.

[0025] (2) After heating the heat treatment furnace to 1020°C, place the titanium alloy sample, keep it warm for 4 hours, and then quench it in water at a water temperature of 10°C to obtain a quenched sample whose structure is all rhomboid martensite.

[0026] (3) Heat the heat treatment furnace to 500°C, place the quenched sample obtained in step (2) into the heating furnace, keep it warm for 4 hours, and then air-cool. The aging structure is nano-twin α phase and β phase.

[0027] Under the same conditions, the hardness of the TC21 titanium alloy three kinds of samples of the raw material forged TC21 titanium alloy, the quenched sample of step (2) and the step (3) aging treatment is tested, and it is found that the TC21 titanium alloy obtained by the inventive method The hardn...

Embodiment 3

[0028] Embodiment 3: the specific steps of this embodiment are as follows:

[0029] (1) Process the TC21 titanium alloy bar after β forging into a titanium alloy sample with a size of 60×60×120 mm.

[0030] (2) After heating the heat treatment furnace to 1000°C, place the titanium alloy sample, keep it warm for 4 hours, and then quench it in water at a water temperature of 10°C. The quenched structure is all rhomboid martensite.

[0031] (3) Heat the heat treatment furnace to 550°C, place it, and put the quenched tissue sample obtained in step (2) into the heating furnace, keep it warm for 3 hours, and then air-cool. The aging structure is nano-twin α phase and β phase.

[0032] Under the same conditions, the hardness of the TC21 titanium alloy three kinds of samples of raw material forged TC21 titanium alloy, the TC21 titanium alloy of the quenched structure of step (2) and the step (3) quenching and aging treatment is tested, and it is found that the hardness obtained by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com