Thermal treatment method for improving mechanical property of titanium alloy strip

A heat treatment method, titanium alloy technology, applied in the field of heat treatment to improve the mechanical properties of titanium alloy strips, can solve the problem of high strength, high toughness and high modulus, complex composition, sensitive alloy structure and performance of TB2 titanium alloy strips and other problems, to achieve the effect of simple heat treatment method, low input cost and good heat treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

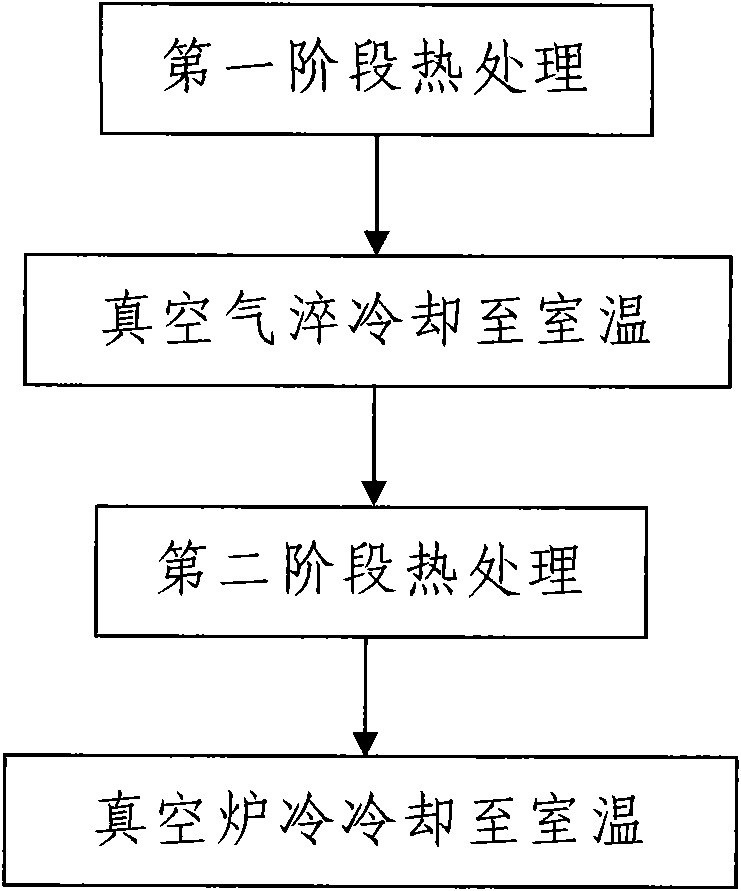

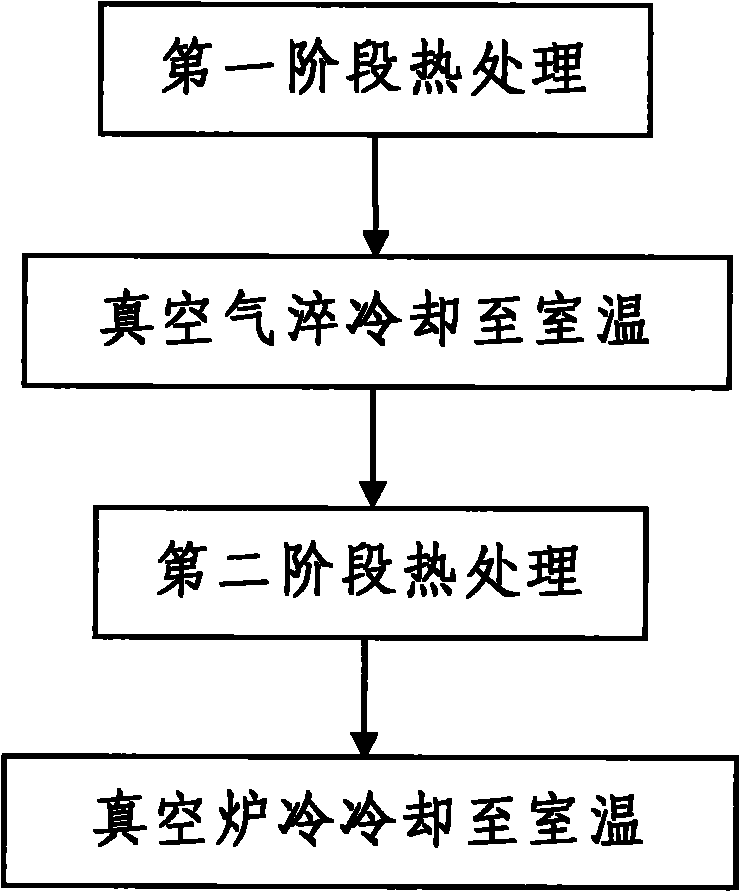

[0021] Such as figure 1 As shown, in this embodiment, the TB2 titanium alloy strip with a thickness of 0.6 mm is treated, and the TB2 titanium alloy strip with a thickness of 0.6 mm is heat treated in two stages. First, the TB2 titanium alloy strip with a thickness of 0.6 mm is subjected to the first stage heat treatment using a vacuum heat treatment furnace, the vacuum degree in the vacuum heat treatment furnace is not less than 10 -3 Pa, the heating temperature is 780°C-820°C, the holding time is 10min-20min, and the treated titanium alloy strip is immediately cooled by vacuum air quenching and then cooled to room temperature. Specifically, when the treated titanium alloy strip is subjected to vacuum air quenching (that is, after being kept at a heating temperature of 790°C for 12 minutes), the cooling is carried out in two stages: first, the cooling is carried out in a temperature not greater than 10 5 Fill the vacuum heat treatment furnace with argon gas at an inflation p...

Embodiment 2

[0025] In this embodiment, the difference from Embodiment 1 is that first, the TB2 titanium alloy strip with a thickness of 0.6 mm is subjected to the first-stage heat treatment in a vacuum heat treatment furnace, and the vacuum degree in the vacuum heat treatment furnace is not less than 10 -3 Pa, the heating temperature is 800°C and the holding time is 10 minutes; and immediately after the holding, the treated titanium alloy strip is cooled by vacuum air quenching and cooled to room temperature. When the titanium alloy strip to be processed is cooled by vacuum air quenching (that is, after being kept at a heating temperature of 800°C for 10 minutes), the cooling is carried out in two stages: first, with a temperature not greater than 10 5 Fill the vacuum heat treatment furnace with argon gas at an inflation pressure of Pa, and rapidly cool the treated titanium alloy strip to 180°C; after that, adjust the inflation pressure of the argon gas to a value not greater than 10 3 Th...

Embodiment 3

[0029] In this embodiment, the difference from Embodiment 1 is: first, the TB2 titanium alloy strip with a thickness of 0.7 mm is subjected to the first-stage heat treatment in a vacuum heat treatment furnace, and the vacuum degree in the vacuum heat treatment furnace is not less than 10 -3 Pa, the heating temperature is 800°C and the holding time is 12 minutes; and immediately after the holding, the treated titanium alloy strip is cooled by vacuum air quenching and cooled to room temperature. When the treated titanium alloy strip is cooled by vacuum air quenching (that is, after being kept at a heating temperature of 800°C for 12 minutes), the cooling is carried out in two stages: first, with a temperature not greater than 10 5 Fill the vacuum heat treatment furnace with argon gas at an inflation pressure of Pa, and rapidly cool the treated titanium alloy strip to 160°C; after that, adjust the inflation pressure of the argon gas to a value not greater than 10 3 The inflation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com