Method for recovering elemental copper from copper-containing wastewater with microbial fuel cell

A fuel cell and microorganism technology, applied in the fields of biochemical fuel cells, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of long start-up time and low copper recovery efficiency, achieve short start-up time, improve recovery efficiency, The effect of reducing the ohmic internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0033] The method for reclaiming elemental copper from copper-containing waste water with microbial fuel cell of the present embodiment comprises the following steps:

[0034] ① Construct a double-chamber MFC reactor.

[0035] The MFC reactor used in this example includes a cathode chamber and an anode chamber with the same volume, and the material is polyethylene. 300mL~500mL (the effective volume in this example is 500mL); the two electrode compartments are separated by a pretreated proton exchange membrane (Nafion TM 212, DuPont). The anode chamber and the cathode chamber are respectively equipped with an anode and a cathode, and the MFC anode is a graphite rod with an effective surface area of 31cm 2 ; MFC cathode is a graphite rod with an effective surface area of 31cm 2 . The two pole chambers are connected with wires, and a variable resistance box of 10Ω~100Ω is connected between the two pole chambers (the resistance is set to 50Ω in this embodiment). The anode...

Embodiment 2)

[0054] The method for reclaiming elemental copper from copper-containing wastewater by microbial fuel cell of the present embodiment is the same as in Example 1, except that:

[0055] The COD value of the anode substrate in step ③ is 850mg / L.

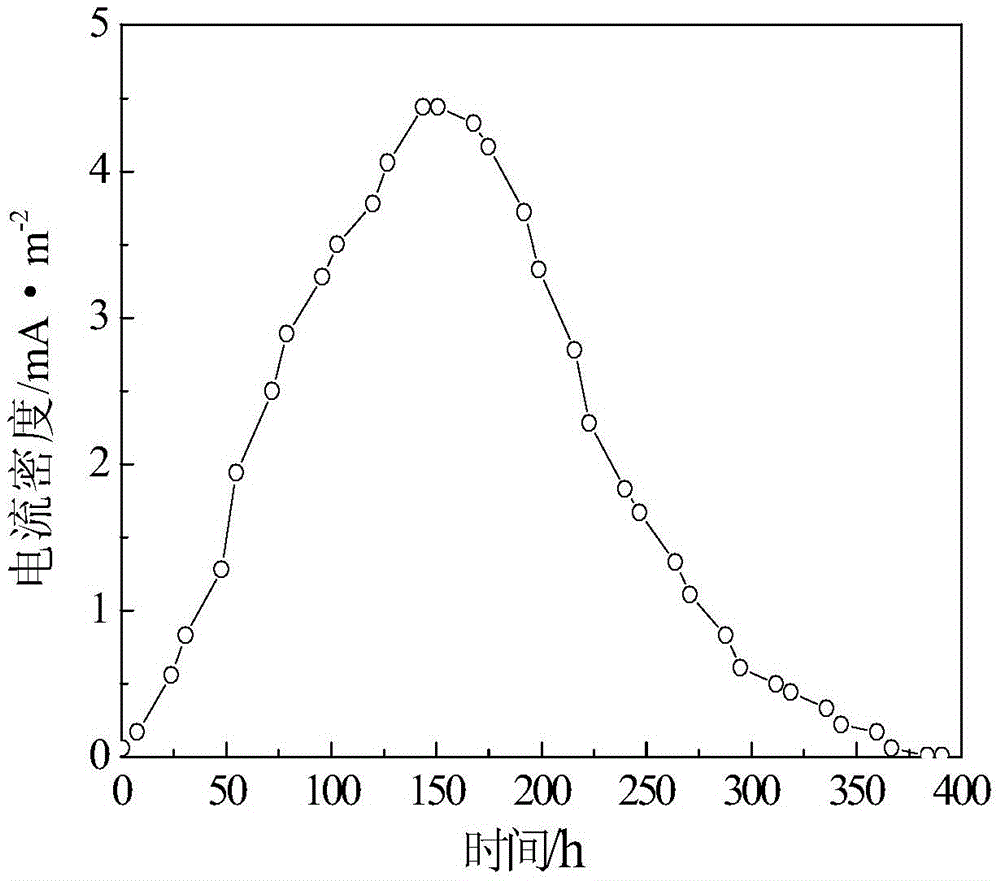

[0056] The power generation performance of the MFC of the present embodiment is shown in Figure 4 , the maximum current density of MFC is 0.6 mA·m -2 . After running for 190 hours, take out the cathode, and use a brush to scrape the bronze-colored deposits on the cathode into the product collector.

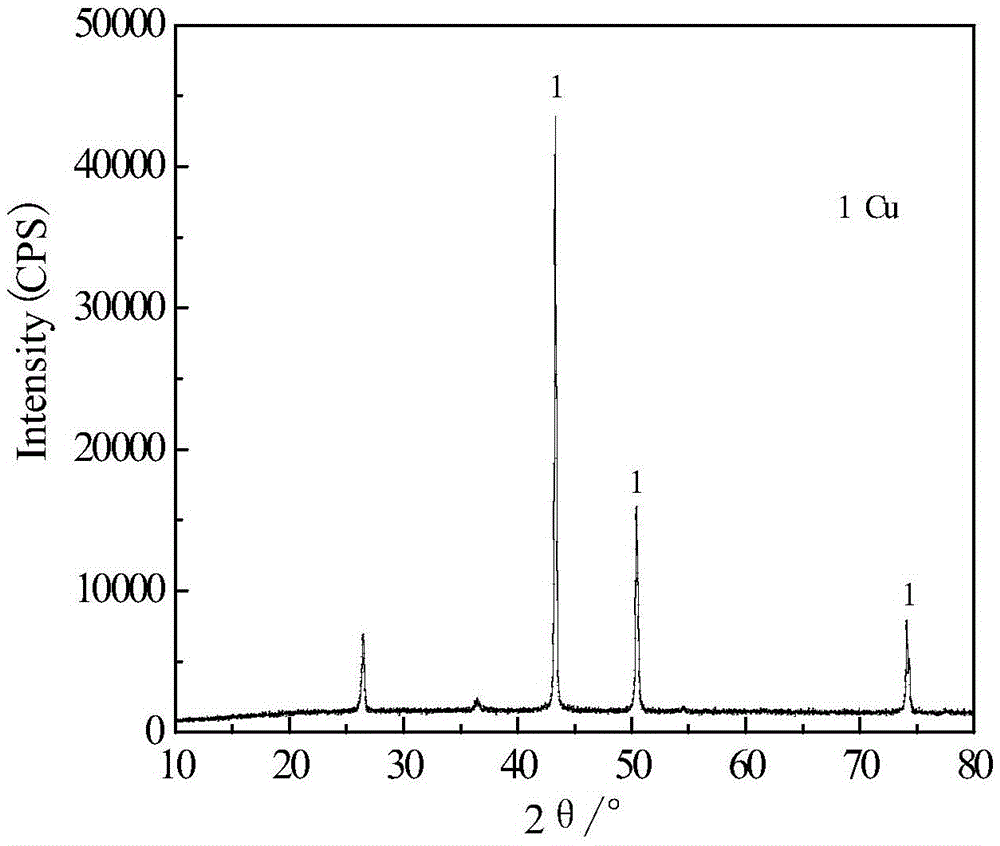

[0057] The XRD diffraction pattern of present embodiment cathode deposit sees Figure 5 According to the detection method of Example 1, sharp diffraction peaks appear in the cathode deposit diffraction pattern at 2θ of 43.9°, 50.4° and 73.6°, which are consistent with the characteristic peaks of elemental copper through computer retrieval; and the characteristics of cuprous oxide do not appear Peaks 36.4°, 43.2° and 61.4° and Cu 4 (OH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com