15*12-mesh polyester plastic-coated pet net production technology

A production process and plastic coating technology, applied in the direction of fabric, coating, fabric surface trimming, etc., can solve the problems of low production efficiency and poor economic benefits, and achieve the effect of crisp feel and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

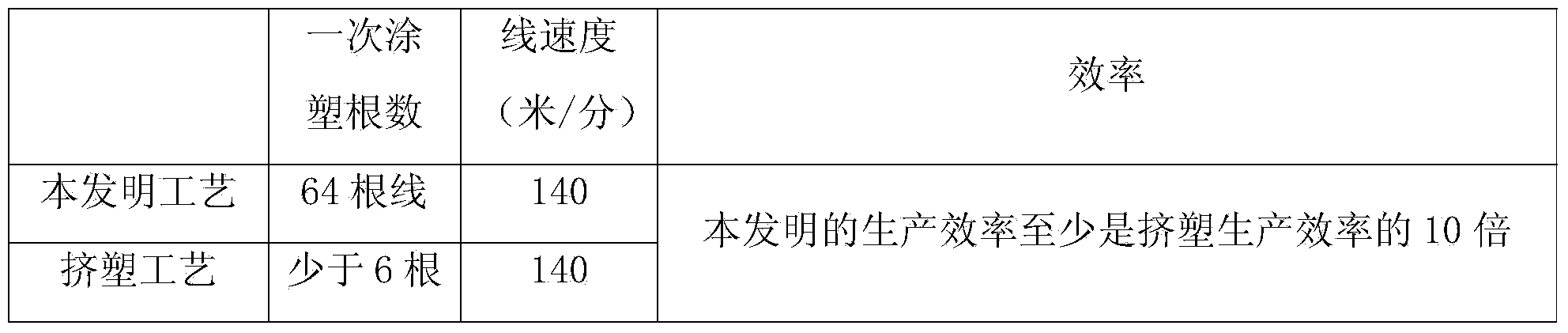

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention will not be limited.

[0013] A 15×12 mesh polyester plastic-coated pet net production process, comprising the following steps:

[0014] (1) twisted polyester filament

[0015] The raw materials have the following properties: 1440dtex / 192F, elongation at break of 15.5% to 11.5%, and breaking strength ≥ 8cN / dtex; in the direct twisting step of polyester filament, the twist of polyester filament is controlled at Z100.

[0016] (2) Monofilament plastic coated

[0017] In the monofilament plastic coating step, the creel tension is controlled to 35N, and the polyester filaments during plastic coating pass through the plastic coating molds with an aperture of 0.55 mm and an aperture of 0.65 mm on the applicator, and then enter an oven at a temperature of 220 ° C. After drying, it is sent to the winding machine; the tension of the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com