A loom broken yarn capture device

A capture device and loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of affecting the safety of loom operation, unable to stop in time, etc., and achieve the effect of preventing random flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

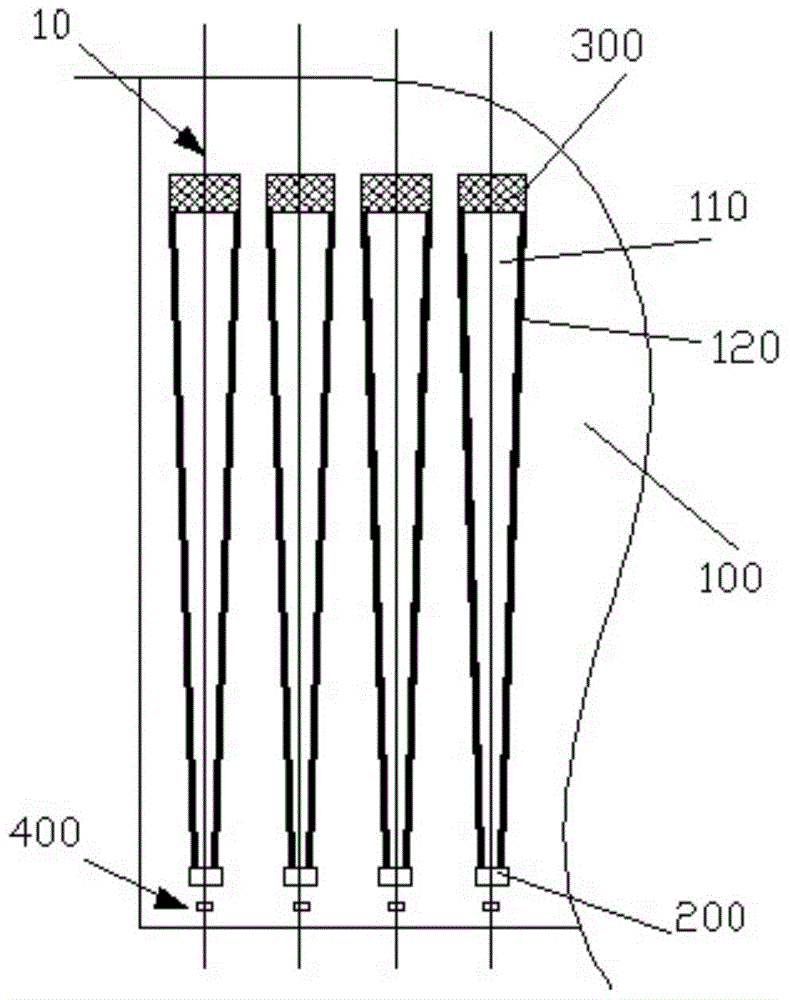

[0014] In this example, see figure 1 The broken yarn capture device of the loom comprises a capture platform 100, the capture platform 100 is arranged in parallel on one side of the warp yarn 10 transmission plane, and the warp yarn 10 is provided with a tablet sensor 400 for monitoring whether the warp yarn 10 is broken, and each Each of the warp yarns 10 is correspondingly provided with a capture groove 110 on the capture platform 100, and the two ends of the capture groove 110 are respectively provided with an air nozzle 200 and an air suction port 300, and the air jet direction of the air nozzle 200 is consistent with the The transmission direction of the warp yarn 10 is the same, the air jet volume of the air nozzle 200 is equal to the air suction volume of the air suction port 300, and the tablet pressing sensor controls the air nozzle 200.

[0015] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com